This article will highlight the technology of laying a soft roof: the tools necessary to perform this work, the procedure for hydro- and vapor barrier and the direct installation of the roof itself.

This article will highlight the technology of laying a soft roof: the tools necessary to perform this work, the procedure for hydro- and vapor barrier and the direct installation of the roof itself.

Soft roofing, which is often also called flexible roofing or flexible (bituminous) tiles, is a modern roofing material with high waterproofing performance, a unique appearance, and it is distinguished by a fairly simple installation technology - soft roofing can be laid without special knowledge and skills. .

This type of roofing roll roofing, in the manufacture of which the latest scientific research is used, has become widespread in our country.

Soft standard roof It is made of fiberglass sheets impregnated with bitumen on both sides, which makes the material particularly airtight.

In addition, the top layer of the material is impregnated with rubber bitumen, which increases the resistance of the soft roof to various damages, and also protects it from exposure to sunlight, preventing the material from fading under the sun's rays.

Another reason for the popularity of the material is that laying a soft roof with your own hands is a fairly inexpensive procedure due to the simplicity of erecting such a roof, which does not require additional costs for inviting specialists from outside, allowing you to save a lot when building a house.

Another advantage of soft tiles is the small amount of waste generated during the installation process. If a soft roof is chosen to cover the house, the laying technology is affordable and simple, not requiring any professional skills, as well as the cost of acquiring special equipment and tools.

You can install such a roof on your own, for this it is enough only the desire to learn something new and diligence.

Before laying a soft roof, you should carefully prepare the necessary tools, as well as make a base for installing soft roofing material.

It is also important to have at least basic skills in handling the tools used when laying the roof.

If a soft roof was purchased to cover the roof - the installation instructions are included in the kit, it is recommended to read it before starting work, and it will also be useful to view various videos on the Internet on the correct installation of the roof.

Preparation of tools and base for soft roofing

You should follow the procedure for laying a soft roof: before proceeding directly to the installation, you should decide what tools will be needed and carefully prepare them.

No special tools for working with a soft roof are required, you only need:

- A standard hacksaw that any person involved in construction will have;

- Roulette for performing various measurements;

- Knife with a sharp blade;

- Always a well-sharpened pencil.

In addition, when a soft roof is laid, the installation technology involves the use of a trowel, with which an adhesive mixture will be applied to the bitumen, and a coil of chalk rope is useful for marking.

To protect your hands when laying a soft roof, it is recommended to use special work gloves.

When, finally, the required material is purchased and all the necessary tools are prepared, you can begin to manufacture the base for the installation of a soft roof.

Before starting work, it is necessary to properly clean, level and dry the surface on which the laying will be carried out.

The rules for laying a soft roof require that installation be carried out on a dry, solid surface, on which there are no various gratings.

In addition, it is recommended to lay moisture-resistant plywood or OSB boards under a soft roof.

At the same time, it is very important to prevent deflections of the roof covering, which can lead to damage and destruction of the roof structure, leading to roof leakage. The quality of the base preparation determines the service life and overall reliability of the structure.

Useful: soft tiles can also be laid on corrugated board.

When preparing the base, it should be taken into account that the slope of the roof to be covered should be at least 11º, which reduces the loads on the roof that can cause damage to the roofing material.

Relatively small - approximately 1.5 kg - the weight of a sheet of soft tiles allows you not to experience difficulties in lifting the material onto the roof with a large slope.

Before a soft roof is laid - bicrost or otherwise, the colors of all sheets should be checked, which may vary in different packages. The packages are opened in advance so that you can immediately distribute the sheets and perform the installation correctly.

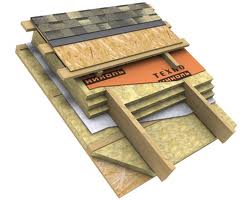

By itself, soft roofing has good waterproofing properties, but it is recommended to improve them with additional waterproofing.

The most commonly used self-adhesive roll materials, which include polyethylene and anti-adhesive films, additionally impregnated with bitumen.

Waterproofing materials are laid parallel to the eaves, with a vertical overlap of at least 20 cm and a horizontal overlap of at least 10 cm.

The installation technology of a soft roof also includes laying a layer of insulation, the effectiveness of which will decrease if steam penetrates and condenses in the space under the roof, leading to the penetration of moisture into the insulation material.

In order to avoid such problems, it is necessary to perform a high-quality vapor barrier of the roof, which consists in laying a vapor-tight diffusion film under the insulation, which prevents the penetration of moisture and steam into it.

The films are laid along the rafters, and their joints should lie on the rafters.

Roof installation procedure

There are various ways of laying a soft roof, depending on the chosen material and its characteristics. Regardless of the choice of method, laying is recommended to be carried out in a warm or even hot season, when sufficiently high ambient temperatures improve the bonding strength of a soft roof due to heating.

In addition, it is important to take into account the design features of the roof itself, since the roofs of residential buildings have a number of differences from industrial and utility buildings that affect how to properly lay a soft roof.

For example, in the design of the roof of the garage, the cornice is either absent or differs significantly from the standard cornice, which should be taken into account when laying a soft roof.

In addition, the garage roof has a very small angle of inclination, which requires additional adjustments in the roof installation process.

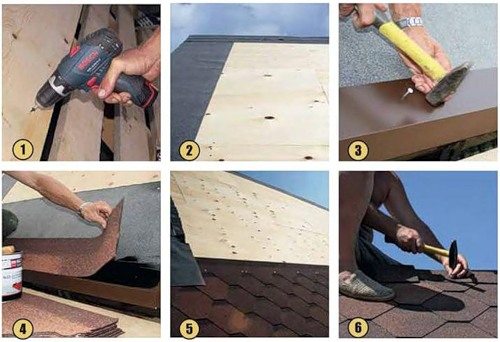

The procedure for installing a soft roof can be divided into three main stages:

- Fastening of the first sheet and cornice row.

- Fastening the next rows.

- Installation of "ridge" sheets.

As already mentioned, the procedure for installing a soft roof is quite simple, the most serious difficulties can arise when laying the main - lower - row, while subsequent rows are laid much easier.

Important: before laying, the surface of the entire roof should be carefully waterproofed by installing a valley carpet along the entire ridge, matched to the color of the roof itself.

After that, you can start laying the cornice row. The first sheet should begin to be laid from the eaves, removing the protective film from it first.

For gluing the sheet, special mastics are used, the choice of which depends on the material chosen for covering the soft roof.

The sheet is laid a few centimeters above the level of the inflection of the cornice, after which the next sheet is laid butt-to-butt to it, and the sheets should be nailed in places of perforation. Similarly, the installation of the entire cornice row is carried out.

Useful: the soft roof material is quite original, since its main rows are installed starting from the center of the roof. At the first performance of work, the laying technology may seem rather complicated, but all the difficulties will disappear after laying several rows, when a certain skill appears, and further work on laying a soft roof will seem quite simple.

Next, the protective film is removed from the next sheet, after which it is glued, heading towards the end parts, and slightly above the groove it is nailed with four nails with a roof slope not exceeding 24º.

With a larger angle of inclination, it is recommended to use not four, but six nails. This method of fastening sheets allows, if necessary, to quickly and easily dismantle them.

When laying, the edge of the first row should be located at a distance of about ten millimeters from the bottom of the eaves row, and the next sheets of this row are installed flush with the petals of the first, after which the excess edges of the roofing material are cut off and glued with mastic.

Important: to improve the sealing of the roof, all its nodes should be glued with mastic.

After the laying of the last row is completed, the installation of ridge sheets begins.

According to the instructions, ridge tiles can be obtained by dividing the cornice tiles into three parts, after which a separate sheet is glued, the short side of which should be parallel to the ridge.

This sheet is nailed on all sides with two nails, which should be nailed so that they are under the next sheet laid on the nailed sheet.

Summing up, we can say that in order to independently perform the installation of a soft roof, it is necessary to evaluate your abilities, strengths and capabilities.

With all the apparent ease of installation of this material, this process will require careful and thorough implementation of all stages of work, and the instructions attached to the material may be incomprehensible in the absence of special knowledge.

Laying a soft roof does not require special tools and skills and allows you to save on inviting qualified roofers, but in this case, you should follow all the rules and instructions for working with it so that the resulting roof serves for a long time and with high quality.

Did the article help you?