This review is devoted to the step-by-step technology for performing work on laying the Shinglas soft roof on the roof. The process is described exactly as recommended by the manufacturer. If you prefer this roofing material, then just follow all the recommendations below.

- Description of the workflow

- Stage 1 - the acquisition of the necessary materials and tools

- Stage 2 - flooring under the roof

- Stage 3 - fastening the lining and valley carpet

- Stage 4 - fastening the eaves and gable strips

- Stage 5 - fixing the roofing material

- Stage 6 - the device of the valley

- Stage 7 - fastening the ridge elements

- Conclusion

Description of the workflow

To make it easier for you to understand the topic, we will break it down into small steps:

- Acquisition of necessary materials and tools;

- The device of a flooring under a roof;

- Laying of underlayment carpet and valley;

- Fastening of eaves and gable strips;

- Fixing the main cover;

- Valley device;

- Fastening elements on the ribs and skates.

Stage 1 - the acquisition of the necessary materials and tools

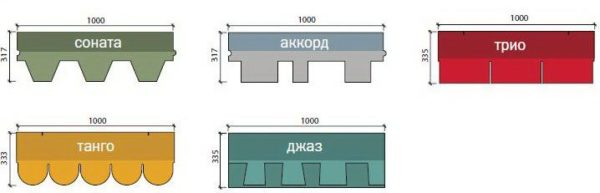

Several collections of products are produced, which are updated annually. But all of them can be divided into several main groups according to the forms of cutting. The main options are shown in the diagram below.

Also, before choosing a specific option, I recommend deciding on the desired color that will suit your home. Within each collection there is a choice of options, so you will find the best solution without difficulty.

If earlier there were single-layer options, now you can buy two and even three-layer products. Of course, the price of such products is much higher, but if you need quality, then there is no point in saving.

Now let's figure out what is needed for work:

- Soft tile - you choose it yourself. The cost varies from 220 to 1200 rubles per square meter. Depending on the type, the service life also varies, for the simplest option it is 10 years, the middle segment lasts 15-25 years, and premium products last 50-60 years. Therefore, the decision depends on your preferences and financial capabilities;

- Lining materials are used to create an additional moisture barrier.They also increase the reliability of fastening the main coating. A self-adhesive version is attached along the edges, and a material with mechanical fastening is attached over the entire area. The cost of the first type of products is 2300 rubles per 15 m2, and the second - 3500 per 40 m2;

- A valley carpet is needed if your roof has internal corners. The material is sold in rolls 1 meter wide and 10 meters long. It is matched to the color of the main coating and costs around 3200 rubles per roll;

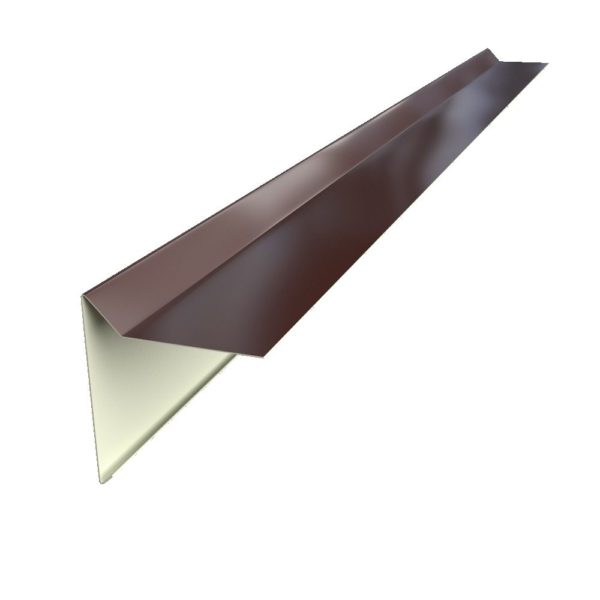

- For cornices and gables, special metal strips are needed. They are made from polymer-coated sheet steel. If you have a roof adjoining vertical surfaces, then you need special slats and for these areas;

- Bitumen-polymer mastic "Fixer" is used for gluing elements in any areas where it is required. A bucket with a capacity of 12 liters costs about 2000 rubles;

- Galvanized nails with a wide head with a diameter of 3 mm and a length of 30 mm are the main fastener when installing the roof. To fix the flooring, you can use self-tapping screws or ruffed nails;

- For flooring, it is best to use OSB boards or moisture-resistant plywood. The thickness should be at least 12 mm, and if the rafters are wide, then even more. A 25 mm thick edged board is also used, but I do not recommend this option due to the fact that the surface will not be as stable.

Recommendations for calculating the required amount of materials are simple:

- Soft roofing is taken with a margin of 5-10%, the exact value depends on the material collection you have chosen. When buying, you will be advised on this matter;

- The valley carpet is calculated according to the area, do not forget to take into account the overlap of 10 cm at the joints;

- Mastic consumption is about 700 grams per square meter;

- Nails are sold by weight, to make it easier for you to count, use the rate of 80 grams per square meter.

From the tool you need the following:

- For sawing sheets, a hacksaw or power tool is used;

- Cutting soft tiles is done with an ordinary knife;

- A tape measure, level and pencil are needed for marking. You will also need a cord to break the roof;

- For cutting metal strips, metal scissors are needed;

- Nails are hammered with a hammer weighing 500-600 grams, use a screwdriver for self-tapping screws.

Stage 2 - flooring under the roof

This part of the work is carried out after the roof structure has been erected and the vapor barrier material has been fixed on it.

The process itself looks like this:

- A vapor barrier is laid on top of the rafters and a counter-lattice is stuffed from a 50x50 mm bar. This will create a ventilation gap under the roof and extend the life of the structure;

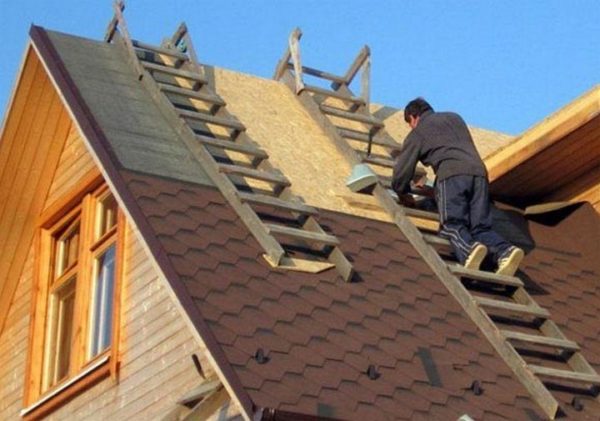

- With large volumes of work, it is easier to immediately lift all the sheets onto the roof, and then use them as needed. On small roofs, the elements are lifted up the skids from the bars as needed;

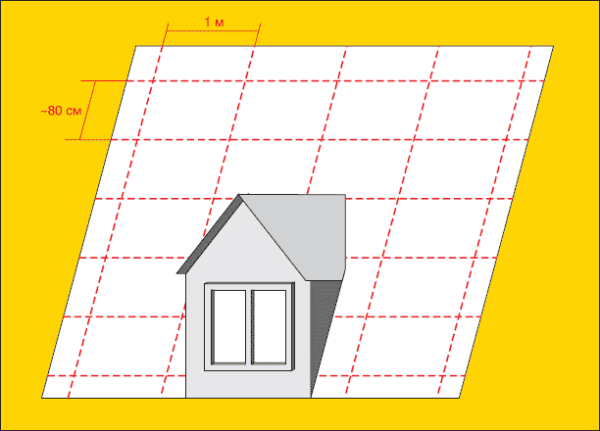

- Work is done from the bottom up. First, sheets of the first row are exposed along the lower edge and fixed with nails or self-tapping screws. The fastening spacing is as follows: 15 cm along the joints, 10 cm along the edge of the roof and 30 cm along the rafters in the middle of the elements. The sheets are arranged in a checkerboard pattern, all the information is very clearly shown in the diagram below;

In order for you to move safely on the smooth surface of OSB sheets, slats are stuffed onto the surface. The step of their location should be such that it is convenient for you to climb or descend the slope.

- Do not forget that gaps of 3 mm should be left between the sheets to prevent deformation during temperature changes. First, all the whole elements are stacked, then pieces of the desired size are cut and put in place.

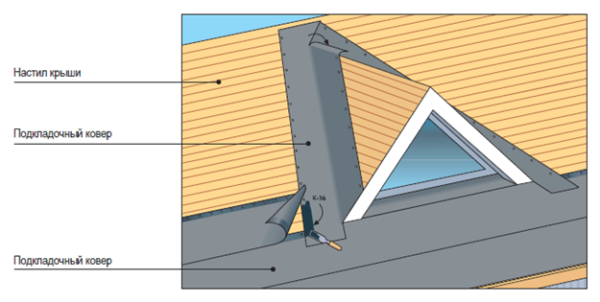

Stage 3 - fastening the lining and valley carpet

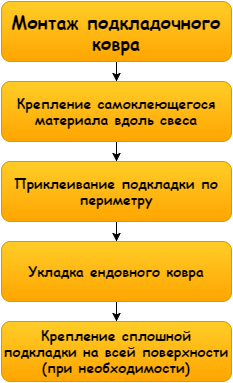

The instruction for this part of the work looks like this:

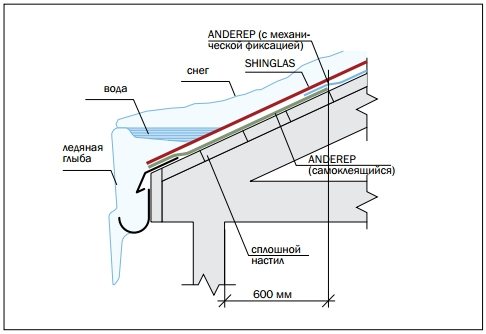

- First of all, you need to stick the strips along the overhang, their width should be 60 cm more than the width of the eaves. That is, the lining is put on the roof 60 cm further than the wall. To make it clear, below is a diagram. This option provides maximum reliability of the roof in all weather conditions;

- Further along the perimeter of all slopes, a strip of the same self-adhesive material is glued. Its width is 50 cm.All joints of sheets are made at least 10 cm and additionally glued with mastic, which is applied in a strip of 10 cm. It is important to evenly place the material and press it tightly over the entire area;

- The valley carpet is laid so that the canvas is located in the middle of the joint. It is desirable that the valley be covered from top to bottom with one sheet, if this is not possible, then the overlap at the junction should be at least 30 cm. The material is fastened with galvanized nails in increments of 15 cm, do not fasten the edge near the overhang at a distance of 15 cm, this is necessary to install the cornice strip;

- If you need a continuous lining carpet, then it is fastened with horizontal stripes from the bottom up with an overlap at the joints of 100 mm. To ensure additional reliability, all connections are smeared with mastic. The pitch of the nails during installation is 150 mm.

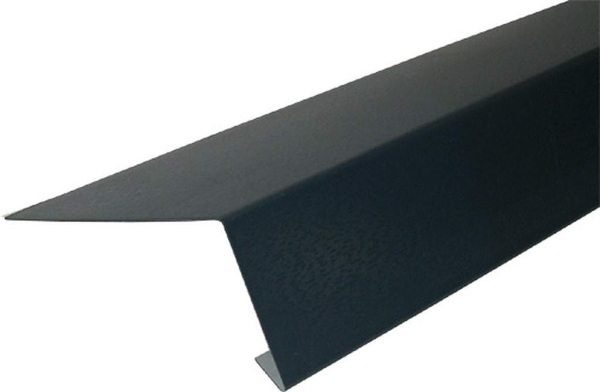

Stage 4 - fastening the eaves and gable strips

To protect the edges of the roof, you need to have a certain set of materials and tools on hand, everything is listed in the table.

| What do you need | Recommendations for use |

| eaves plank | Its second name is a drip, it has a special shape for effective water drainage. It is better not to make homemade corners, but to buy ready-made elements. When calculating, take into account an overlap of 5 cm on the joints |

| Gable plank | Its width must be at least 100 mm for reliable protection of the ends of the roof |

| Tool | For cutting, scissors for metal are used, for fastening a hammer. You can coat the joint with mastic, but this is not necessary |

The workflow looks like this:

- You need to start from the edge of the roof, the first element is carefully placed along the edge of the overhang and nailed. They are arranged in a zigzag every 10 cm. This method of fastening ensures maximum reliability of the structure. Nails are hammered in carefully, they should not stick out above the surface, but they should not deform the metal either;

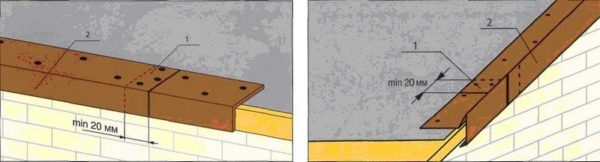

- At the joints, overlaps of at least 20 mm are made, but it is better to make them 30-50 mm for reliability. Connections are fastened as shown in the figure below. By the same principle, the cornice elements are joined, which will be discussed below;

- Above, I paid attention to the fact that it is not necessary to fix the valley carpet. When you have laid the drip, the carpet is glued to it from above with mastic and cut out along the edge of the overhang. It turns out a very reliable connection;

- Cornice elements are attached from the bottom up so that the joints are closed from water. They should go to the drip at the edges, so they are attached after it. If necessary, the elements are trimmed with metal scissors;

- Before fastening, the plank is aligned along the edge of the gable. Installation is carried out in the same way as in the case above: nails are hammered in a zigzag pattern with a step of 100 mm. You can additionally fix the elements on the side.

Stage 5 - fixing the roofing material

Installation of a soft roof Shinglas is carried out as follows:

- First of all, you need to mark the surface of the roof. This will allow you to control the laying line and provide the best result. Horizontal lines are made every 80 cm, these are 5 rows of flexible tiles. The vertical gap is 1 meter - across the width of the sheets. The markup can be done with chalk, pencil or something else, the main thing is that you see it when you work;

Work should be at temperatures above +5 degrees. If it is colder outside, then even warm shingles from the room will not stick very well.

- 4-5 packs are taken, the packages are opened and mixed with each other so that the surface has the same shade without pronounced spots. In order for the sheets to separate well, the pack can be shaken and bent several times before opening. You simply take the sheets one by one from each pack and put them in a common pile;

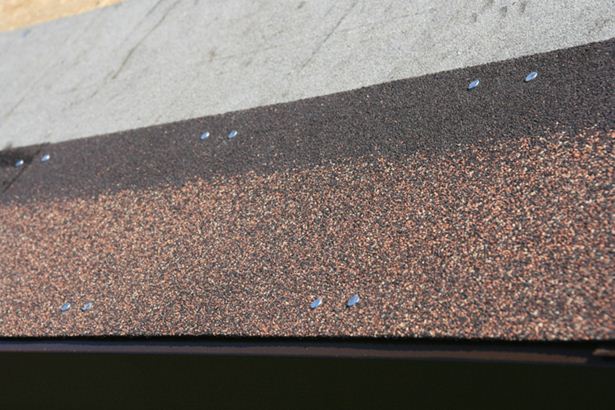

- Mounting starts from the middle of the slope. The first row is a cornice tile, which is a flat strip with perforation. If there is no special material, it's okay, an ordinary tile is taken, and the petals are cut off. The material is laid with an indent of 1-2 cm from the edge of the cornice strip and fixed with nails as shown in the photo below;

- Laying ordinary tiles starts from the middle of the roof slope. The first row is positioned so that it is 5 mm above the edge of the cornice material. It is important to align each sheet to prevent the row from being skewed. It is desirable to lead the rows in this way - from the middle to the edges, this allows you to best control the laying line;

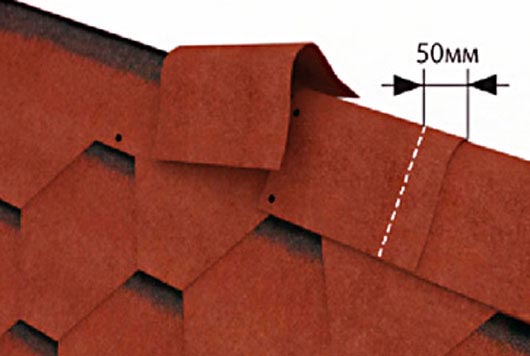

- Fastening is simple: a nail is hammered over each cutout with an indent of 2-2.5 cm from the edge. Everything is very simple and fast. The main thing is not to forget to remove the protective film from the self-adhesive layer, which is located on the reverse side. When driving nails, make sure that they are even and flush with the surface of the roofing material;

- Usually, each subsequent row is shifted by half a petal. But some collections need to be shifted more. To know how to arrange the sheets, just read the information on the package. There is always a brief manual for laying your own hands;

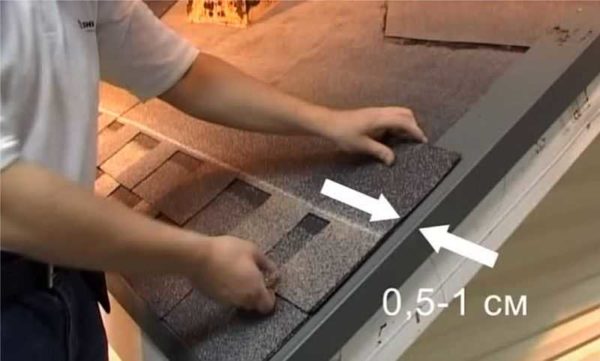

- As for the edges of the roof, it is necessary to cut the sheets so that they are indented 5-10 mm from the edge of the gable strip. Cutting is done on a board or plywood so that when you work you do not damage the surface under the shingle;

- To ensure reliability, the extreme elements, in addition to fastening with nails, should also be glued to the mastic. The composition is applied along the edges with a strip of 10 cm, the layer thickness should not be more than 1 mm.

Stage 6 - the device of the valley

If you have a straight roof, you can skip this step.

But if you have valleys, then their protection from moisture should be given the closest attention, the work consists of the following steps:

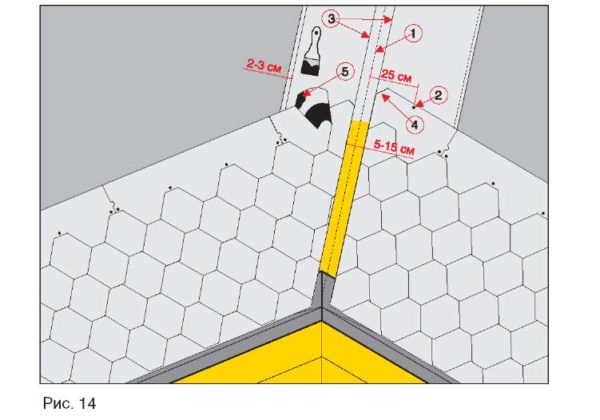

- The shingles are first laid without trimming. Near valleys they are fastened with nails both in the upper and lower parts at a distance of 25-30 cm from the connection of the slopes.There is no need to nail closer, since we have to perform additional work to isolate the connection. The general scheme of work is shown below;

- Lines are drawn along the surface of the valley at a distance of 2.5 to 7.5 cm from the axis of the structure. That is, in the end, the open part will be from 5 to 15 cm. I recommend making a 5-7 cm gutter, it looks much neater than wide options. You can smear the surface along the valley in advance, or you can do it after cutting, the strip width should be at least 10 cm;

- Shingles are cut along the line. In order not to damage the valley carpet, a plank or a piece of plywood is placed under the sheets. Work carefully so that the line is even, the appearance of the roof depends on it;

- After cutting, the elements are carefully glued to the mastic, pressing each section to ensure that the shingles are firmly attached.

Stage 7 - fastening the ridge elements

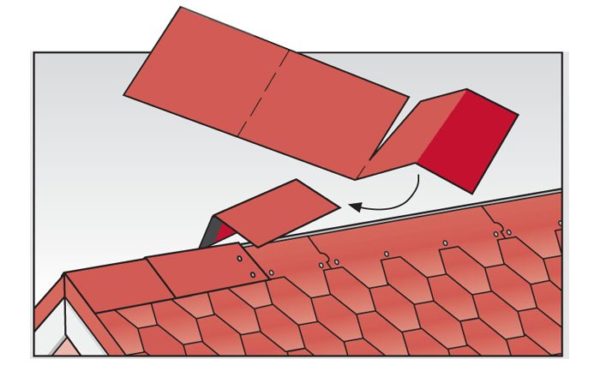

For work, cornice-ridge elements are used.

If we fastened them entirely from below, then on skates we will tear each sheet into 3 parts along specially applied perforated lines.

- Work begins on the side opposite to the prevailing wind direction in your area. The extreme element is additionally taken on the mastic over the entire area and nailed with four nails - 2 on each side;

- The nails are positioned so that they are covered by the next shingle.The overlap on the joints should be 5 cm, so it is best to fasten the elements at a distance of 3-4 cm from the edge. The diagram below shows everything clearly;

- When attaching, make sure that the elements are well glued to the surface and are evenly spaced. The work is simple, but requires accuracy and precision.

Conclusion

After studying this article, you can easily lay the Shinglas soft roof no worse than professionals. The video in this article will help you understand some of the nuances even better and clearly show the workflow. If you have any questions - write them in the comments below.

Did the article help you?