Installation of a soft roof is considered by many developers to be very difficult, but in reality it is not so. If you study the technology presented in the article and follow a clear sequence of work, you can easily cope with this task. To make it even easier for you to understand all the nuances, we have broken the whole process into 10 stages.

- Description of the workflow

- Step 1 - preparing materials and tools

- Step 2 - attaching the base to the truss system

- Step 3 - laying the underlayment

- Step 4 - fastening the cornice and gable strips

- Step 5 - laying the valley carpet

- Step 6 - fixing the cornice tiles

- Step 7 - laying ordinary elements

- Step 8 - junctions to the valley

- Step 9 - chimney connections

- Step 10 - fastening the ridge elements

- Conclusion

Description of the workflow

Installation instructions for a soft roof will consist of the following steps:

- Preparation of materials and tools;

- Floor fixing;

- Installation of lining carpet;

- Installation of metal elements on gables and cornice overhangs;

- Laying of the valley carpet;

- Fixing cornice tiles;

- Laying ordinary elements;

- Installation at the junction with the valley;

- Protection of chimney connections;

- Fastening of ridge elements.

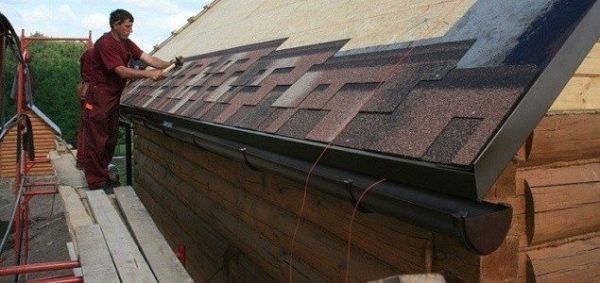

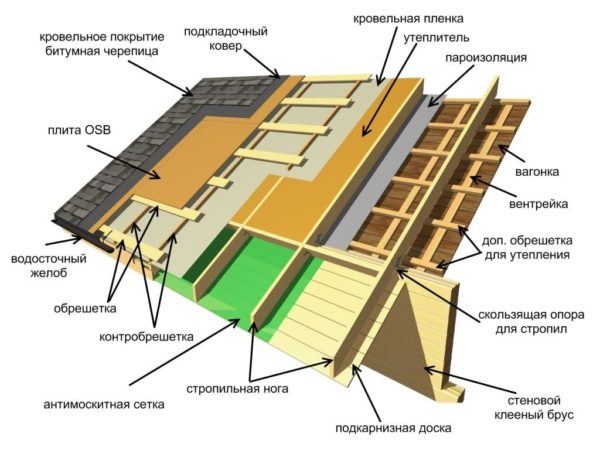

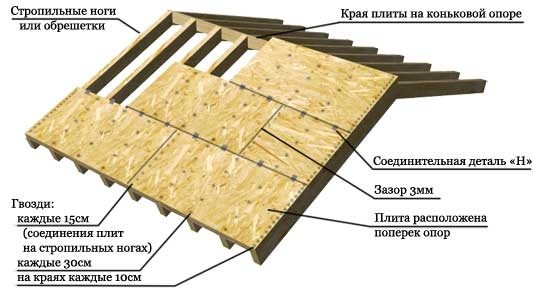

It is better to entrust the construction of the truss system to professionals, this is the type of work that it is better not to perform without experience.. On the roof, a crate must be fixed. The optimal design is shown in the diagram below. We will analyze the part of the work that relates to the installation of roofing.

The minimum roof slope for such coatings is 12 degrees. It is better if this figure is higher.

Another aspect that you need to know is at what temperature to lay a soft roof. The minimum threshold is +5 degrees, but it is better to work at +15-20. At temperatures up to +10, the roof elements must be heated with a building hair dryer for their better adhesion.

Step 1 - preparing materials and tools

Any work begins with the collection of everything you need. The list is shown in the table below.

| Material | Description |

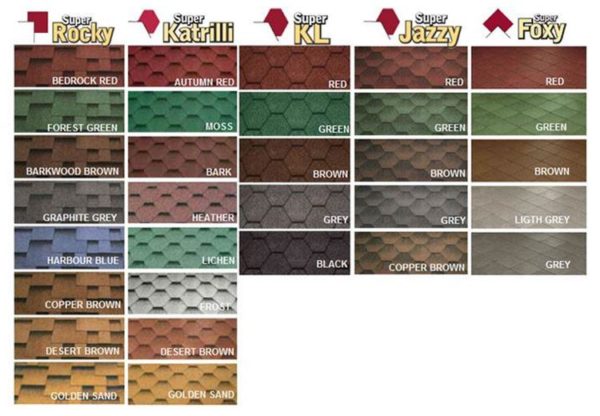

| Soft roof and accessories | It makes no sense to consider all the elements, since the calculation is usually made by the selling company. This service is free, and you need to provide a roof plan, the rest of the work will be carried out by specialists. This greatly simplifies the process, since you do not have to sit through complex calculations. |

| OSB boards | The easiest way to use moisture-resistant elements of this particular type. I tried both edged board and moisture-resistant plywood, but OSB is much more convenient to work with and stronger. At the same time, the price of the material is quite democratic. |

| metal elements | Planks for cornices and gables are not always sold with the roof. If this is the case for you, then you need to purchase these products separately. When buying, you need to know the length of the structures in running meters. To the results obtained, a margin for docking is added (the joint should be 2-5 cm) |

| fasteners | Bituminous tiles are fastened with roofing nails. And for OSB, use self-tapping screws 4-5 cm long, depending on the thickness of the sheets |

As for the tool, you need such a set:

- To cut OSB boards, you need an electric saw or electric jigsaw;

- Self-tapping screws are tightened with a screwdriver;

- If you need to heat the elements for their better gluing, you need a building hair dryer;

- Nails are hammered;

- The tile is cut with an ordinary construction knife. Tin elements are cut with scissors for metal;

- If the adhesive composition is in cylinders, then you need a gun for sealant;

- For measurements and markings, a tape measure, a level, a chopping cord and a pencil are used.

Another important device is a special ladder, it is made of a bar and boards. With its help, it will be safe to move on roofs with a large slope. The design differs from the classic version in that two bars are nailed and reinforced with braces in the upper part, which are held by the ridge. Everything is simple and reliable.

Step 2 - attaching the base to the truss system

First you need to create a solid foundation for flexible tiles. I wrote above which material is best, but if you do not have the opportunity to use OSB, then moisture-resistant plywood or edged board will do.

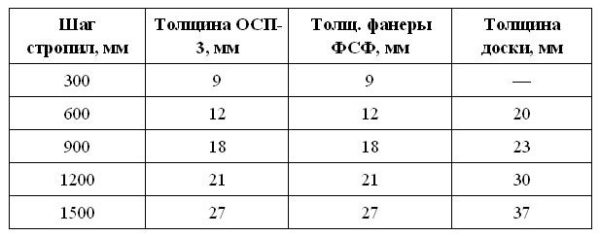

As for the thickness of the material, it depends on the pitch of the rafters. To make it easier for you to choose the best solution, below is a table with all the information for all three options.

The sheet mounting technology is very simple:

- Elements stacked across rafters. Vertical seams should not match, that is, every second row starts with a half of the element. It is easiest to cut products on the ground with a power saw (a jigsaw cuts worse). The main thing is to correctly mark the sheets so as not to spoil them;

- Sheets are lifted with a rope and two bars. Most often, fastening is done using self-tapping screws. But if you have an electric hammer, then you can fix the material with nails, it will be faster. For fixing, use nails three times longer than the thickness of the OSB;

- A deformation gap of 3 mm wide must be left between the sheets. As for the fastening step, it is 10 cm along the edges, and 15 cm along the rafters in the middle. When carrying out work, make sure that the fastener heads become flush with the surface and do not stick out above its level.

Step 3 - laying the underlayment

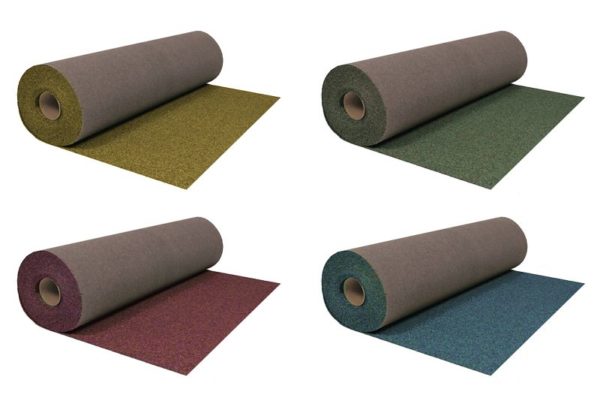

The lining layer increases the reliability of the roof and allows for additional waterproofing in difficult areas of the roof. The material is sold together with the roof and can be installed in two ways.

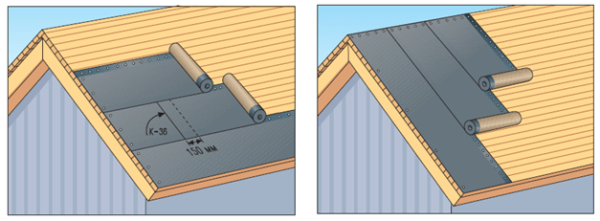

The specific option depends on the slope of the roof, if it is from 12 to 18 degrees, then the work is done as follows:

- On such slopes, the lining spreads over the entire surface. You can arrange the material both horizontally and vertically. When laying horizontally, the strips are laid from the bottom up, the overlap at the joints should be at least 100 mm, when connecting pieces in one row, the overlap is at least 150 mm. With a vertical arrangement, the requirements are the same;

- Elements are fastened with nails in 20 cm increments, the same hardware is used as for soft roofing. At the joints, the canvases are coated with a special mastic, this allows you to seal the joints and increase the reliability of the lining. The composition is applied in an even layer over the entire joint area. The edges along the perimeter of the roof are also planted on the mastic;

- To ensure reliability along the ridge, a second layer is fixed on top of the first layer.The sheet is positioned so as to cover the same distance on both sides. The element is glued along the edges, the mastic is applied in a strip of 10 cm. After that, the final reinforcement is made with nails.

If the slope of the roof is more than 18 degrees, then it is not necessary to lay a solid carpet. You can get by with partial insulation, manufacturers allow this option.

Here the work is done like this:

- The lining layer is laid along the edges of the overhangs and along the gables. The width of the strip should be at least 50 cm. The edges of the sheets are smeared with mastic and glued, after which they are fastened with nails. Everything is quite simple and fast;

- If there are pipes and other protruding elements on the surface, then the space around them is also isolated. At the same time, the lining carpet should go on vertical surfaces by 20-30 cm. The material is carefully glued, and where possible, nailed.

Step 4 - fastening the cornice and gable strips

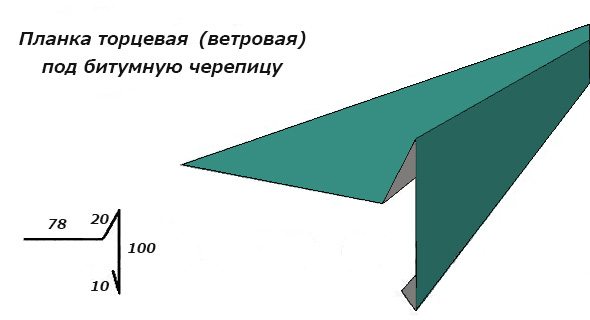

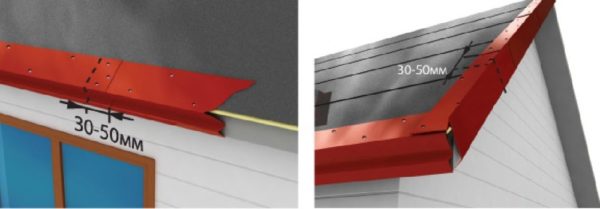

On top of the lining carpet around the perimeter, special metal elements are attached. They protect and reinforce the edges of the roof structure and improve the appearance of the finished roof. Products are made of tin and are selected according to color roofs.

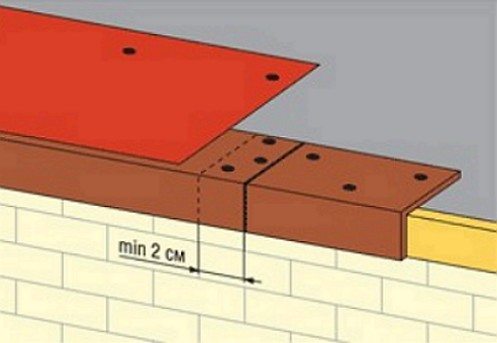

The fastening of these elements is carried out according to the following technology:

- First, the cornice strips are fixed.The bend of the elements must coincide with the roof overhang, at the joints an overlap of 3-5 cm is made to ensure reliability. Fastening is done with nails, which are arranged in a zigzag pattern with a step of 100 mm. At the joints of the elements, 3-4 nails are hammered in for a strong fixation;

- The wind bar is attached and joined in the same way as the eaves. It is important to remember here that the lower part always starts under the upper one, and the gable element at the junction with the eaves is always located on top. . At the junction, the nails are hammered in increments of 3-5 cm to ensure reliability.

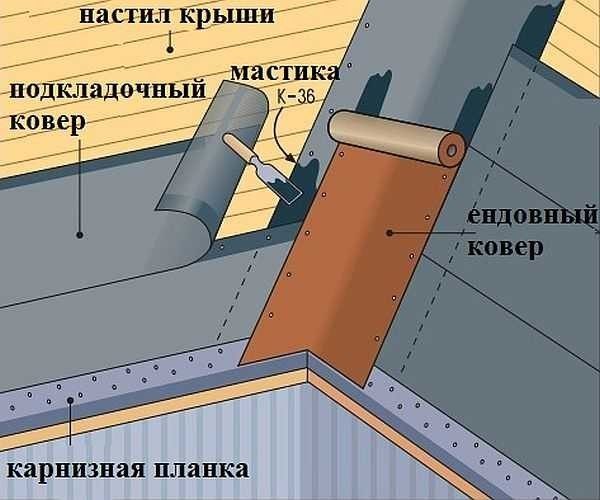

Step 5 - laying the valley carpet

If there are valleys on your roof, then they need to be given special attention. For work, a special valley carpet will be used, which is matched to the tone of the future tile. If desired, you can choose a contrasting shade to highlight the joints, but this option is more suitable for roofs with complex curves.

Let's figure out how to properly lay a valley carpet with your own hands:

- First of all, the surface should be cleaned of dust and dirt. There is already a lining carpet on the plane, it is this that needs to be wiped;

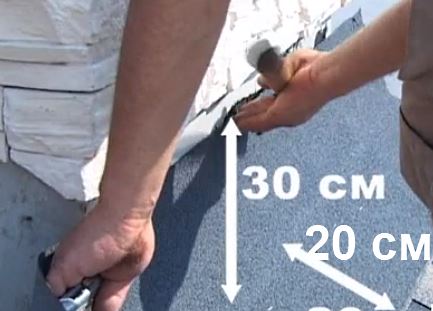

- It is desirable that the entire valley from beginning to end be covered with one sheet of material. So you will ensure maximum reliability and eliminate any problems in this area.. If you still need to join the pieces, then the overlap at the junction should be at least 20 cm, and preferably all 30, in order to protect the mating as best as possible;

- In the lower part, the material is cut out according to the shape of the joint, the carpet is laid over the cornice strip. Along the perimeter, the element must be glued with mastic, which is applied in a strip 10 cm wide. After that, you can finally fix the material with nails.

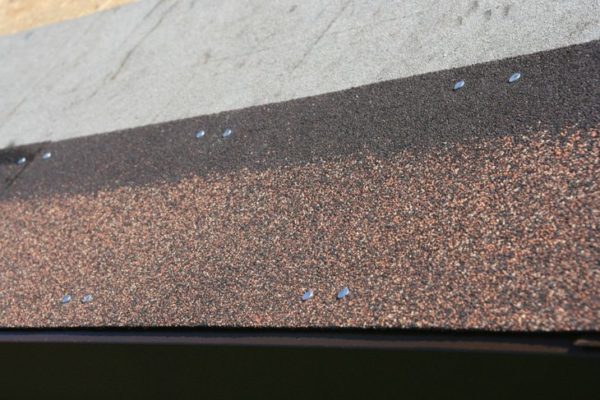

Step 6 - fixing the cornice tiles

The bottom row is made of the so-called ridge-cornice shingles. They are a flat strip without petals with perforation for division into three parts. In our case, there is no need to divide anything, we will use the elements as a whole.

Now let's figure out how this roofing material is laid:

- For convenience, I advise you to mark the surface with lines. The vertical ones should be equal to the width of the sheet, and the horizontal ones should be equal to the spacing of the shingles. This will make your work easier and prevent distortions;

- Sheets are placed with an indent of 8-10 mm from the edge of the cornice strip. First of all, you need to remove the protective layer from the self-adhesive areas, and the places where there is no glue should be lubricated with mastic. That is, you must have an element whose bottom part is completely adhesive. The shingle is neatly placed on the surface and pressed for a secure fit;

- The final fastening is done with nails. For reliability, you can beat them either from above or from below, 2 pieces each. Moreover, the bottom row is located so that the nails are closed with protrusions on the roofing sheets. You can estimate in advance to determine the attachment points.

If you don't have cornice shingles, you can use ordinary ones.But before applying, you need to cut off the protruding areas.

Step 7 - laying ordinary elements

Ordinary are the main elements, sheets with cutouts, from which the surface will be assembled. Laying a soft roof is very simple, but at the same time requires accuracy and precision.

The process itself looks like this:

- First of all, you need to unpack 5-6 packs and mix their contents. So you avoid color differences and achieve maximum uniformity of coverage.. You can also remove the protective film so as not to be distracted on the roof, in half an hour the sheets will not stick together, and it will be easier for you to work;

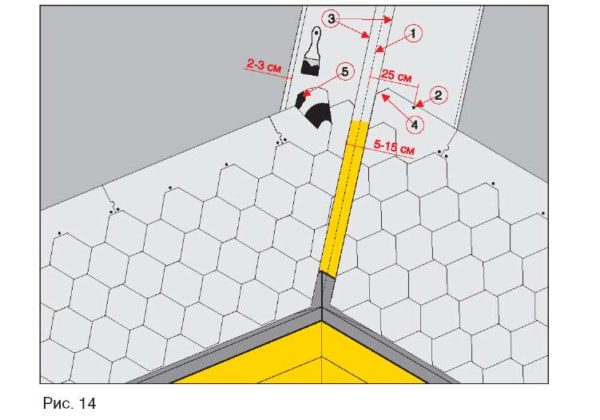

- Work is done from the bottom up. The first row is located with an indent of 5-10 mm from the edge of the cornice sheet. The installation scheme for a soft roof involves fastening sheets from the center to the sides. This allows you to clearly draw a horizontal line and avoid distortions;

- Each shingle is stuck with four nails, which are hammered over the cutouts of the sheet with an indent of 2-3 cm. Before fastening, do not forget to remove the protective layer from the self-adhesive strip from the bottom to fix the elements even better. Nails are hammered so that the hat is flush with the surface;

- The junctions with the gable planks should be smeared with bituminous mastic, the application width should be approximately 10 cm. It is better to cut the sheet in place - glue it and cut it along the bending line of the metal element. It turns out very accurately and very smoothly;

- The next row also starts from the middle, only the sheet is offset to increase the reliability of the roofing. The lower part is aligned with the cut line, after which the shingle is glued and nailed. The work is done in this way until you cover the entire surface, the main thing is to place the sheets evenly and fasten firmly.

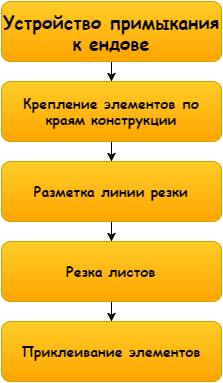

Step 8 - junctions to the valley

The installation of a soft roof involves ensuring the best reliability, which is why special attention is paid to the valleys.

The work is done according to the following algorithm:

- The sheets are nailed so that they go into the junction of the surfaces. Nails can be hammered no closer than 30 cm from the joint;

- Along the junction of the valley you need to draw lines on both sides. The width of the open groove should be from 5 to 15 cm, it all depends on the configuration of the roof. I recommend making it narrower for more reliability;

- Sheets need to be cut along the line. In order not to damage the valley carpet, a batten or a piece of plywood is placed under the soft roof. Then you can press hard on the knife and cut the elements along the line with high quality, doing the work with maximum accuracy;

- After cutting, all the corners of the shingles located near the valley are cut to repel water, after which the surface is smeared with mastic and glued. Apply the compound to the entire width of the shingles from the nailing point to the edge, then press them to the surface.

Step 9 - chimney connections

If you have a chimney on the roof, then the place of its exit to the surface must be protected from moisture especially carefully.

When I carry out the installation of a soft roof on a roof with a chimney or other pipe, I use the following work technology:

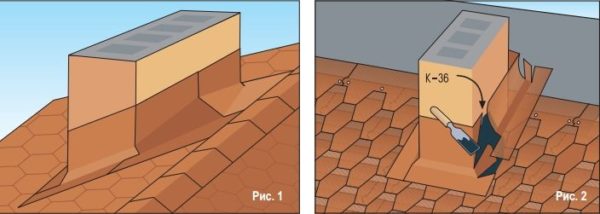

- Even at the stage of laying the lining carpet around the perimeter of the chimney, you can lay a triangular rail. If it is not there, it's okay, but if possible, then it is better to put this element to improve water flow;

- Ordinary tiles are placed with an overlap on the pipe of 5-7 cm and glued. A valley carpet is glued on top of it, it should go onto a vertical plane by 30 cm. The element is glued to the surface of the brick with a special sealing compound K-36, it is necessary to generously lubricate the surface and press the sheet well, after leveling it;

- A strobe is cut along the line above the waterproofing material, into which an abutment bar is planted on the sealant. In addition, it can be fixed with quick fixing dowels. Overlaps on knocks should be at least 5 cm to ensure reliability.

Step 10 - fastening the ridge elements

There are two options for carrying out work - with and without a ridge aerator.

Let's figure out how the work is done if the skate with an aerator:

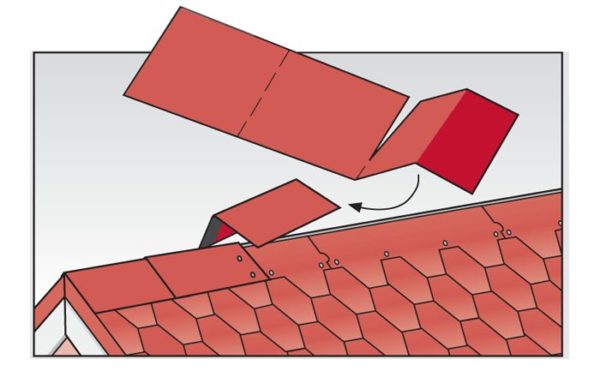

- First, a plastic element is taken and placed in its place. After that, the assembly is fastened using the same nails that were used for soft roofing;

- Next, ridge elements are taken, they have perforation, along which they can be torn into three parts.After that, the pieces are bent in half, this will be the work item. The diagram below shows everything in detail;

- Sheets are fastened one after another with four nails. The overlap of each next element is 5 cm, while the nails are arranged so that they close and are not visible after the work;

- After completion of the work, the roof is ready for operation, the extreme elements, if necessary, are cut along the cornice strips.

For roofs without aerators, it's even easier, you have to cut the shingles and nail them.

Conclusion

Installing a soft roof is not an easy process, but if you follow all the recommendations outlined above, you can make the roof yourself. This will save a lot of money, because the services of specialists are not cheap.

The video in this article will help you understand the topic even better, and if you have any questions, then write them in the comments below.

Did the article help you?