Lightning protection of a private house with a roof made of metal or any other roofing material is very important. Proper installation of the protective circuit makes it possible to protect the building from a fire resulting from a lightning strike. The design of lightning protection is quite simple, and therefore you can make such a system yourself. What is needed for this and how to install - I will tell below.

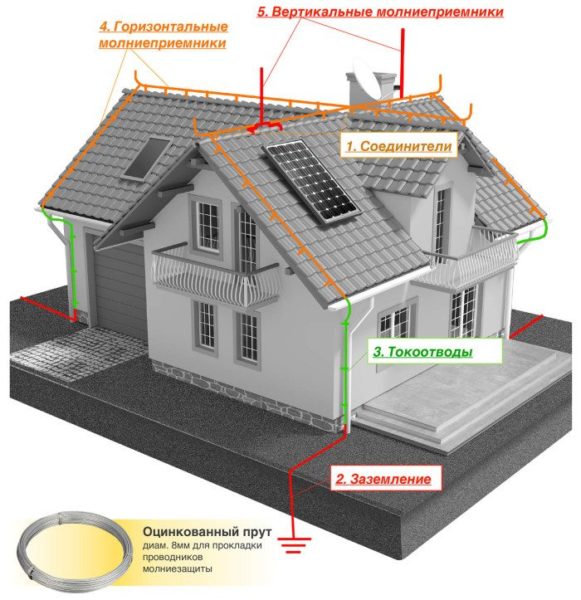

System elements

A lightning strike on an unprotected roof of a building can lead to the most serious consequences. Thunderstorm fires are not uncommon, especially if the affected building was made of combustible materials. That is why the presence of lightning protection will help you save not only property, but also health, and sometimes life.

The principle of operation of the lightning diverter circuit, which is installed in private houses, is simple:

- The lightning rod is responsible for capturing the electric discharge. It is usually represented by a metal structure, which is located on the ridge of the roof (sometimes going on the slopes).

- The lightning discharge, caught by the lightning rod, is transmitted further along the current-carrying circuit. This circuit is made of copper, aluminum or steel wire. It connects the receiving pin, cable or mesh to a grounding structure located in the ground.

- Grounding - a circuit of metal strips or rods, which ensures the discharge of the discharge into the thickness of the soil. As a rule, it is buried at least 0.8 - 1 m deep into the ground, which provides effective lightning neutralization and increases the overall level of security.

According to this principle, the so-called passive lightning protection of the house is equipped. It does not require additional energy sources for its operation.

An alternative is an active protection system:

- The main part of such a system is an active lightning rod, which is mounted at least 1m above the highest point of the building (most often it is a chimney).

- The device ionizes the air at a certain distance around itself, which allows you to effectively intercept lightning within a radius of up to 100 meters.

- In the future, the lightning charge, just as in the case of a passive system, is transmitted through a current-carrying circuit to the grounding system.

The disadvantage of such a system is the need to connect it to the electrical network, as well as a rather high price. On the other hand, the efficiency of active devices is higher than that of passive devices, therefore, for example, it is worth spending money for an expensive wooden house.

The main documents regulating the installation of protective circuits are:

- RD 34.21.122-87 "Instruction for lightning protection of buildings and structures";

- SO 153-34.21.122-2003 "Instruction for lightning protection of buildings, structures and industrial communications".

Protective circuit installation

Lightning rods of different types

Lightning protection in a private house may well be mounted independently. In this section, I will tell you what parts it consists of, and I will start with the most important one - with a lightning rod.

It is a metal element that takes the first hit and provides charge trapping. Thus, instead of causing damage, lightning energy is redirected to the ground loop.

The lightning rod can have a different design. The most common types I will briefly describe in the table:

Types of lightning rods

| Type | Peculiarities |

| Rod | The simplest design that is suitable for a metal roof. The detail is a metal pin 1.5 - 2 m high, installed vertically at the highest point of the roof.As a rule, a chimney or an antenna is used to fasten the rod, a little less often a lightning rod is placed on a wooden support fixed on the ridge. For manufacturing, you can use materials that are subject to minimal oxidation when in contact with precipitation - copper, stainless steel, etc. The optimal thickness of the round rod is from 12 mm or more. If a hollow metal tube is used to mount the receiver, then its upper end must be welded or rolled. |

| Rope | It is a metal torso or wire mounted on wooden supports above the roof ridge. It is allowed to use a metal supporting frame, but in this case the lightning rod itself is isolated from the supports using ceramic inserts.

For wooden roofs, the optimal cable tension height is 1 - 1.8 m from the ridge, for roofs made of non-combustible material - from 10 cm. |

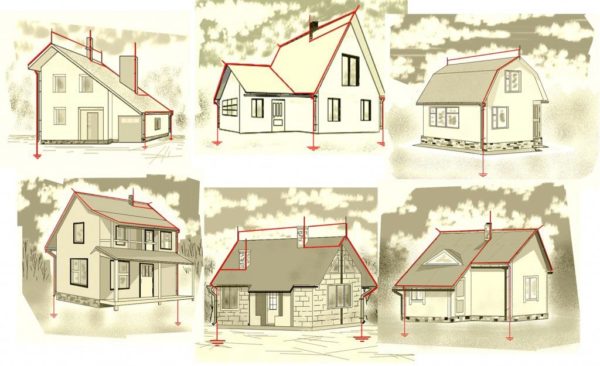

| Reticulate | For a tiled roof, a trapping mesh is the best option for a protective contour. It is mounted on a ridge, and down conductors connected to a common ground loop depart from it over the entire surface of the slope. |

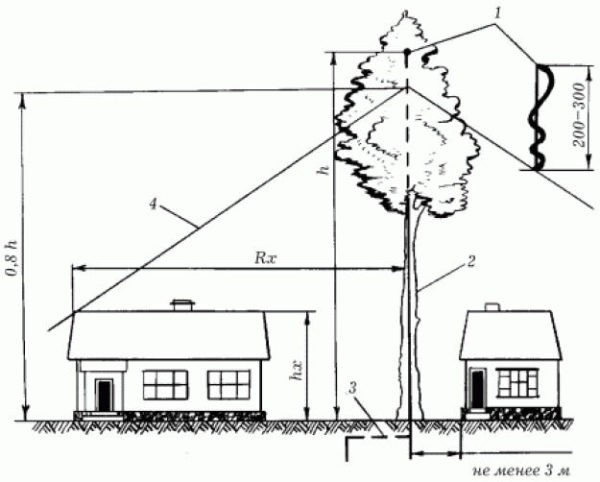

The charge receiver, especially the rod one, can be attached not only to the ridge on the roof, but also to a tree growing nearby. At the same time, the height of the tree must be at least 10-15 m higher than the house, otherwise the system will not be effective enough.

The tree should grow at a distance of 5-10 m from the structure that we are protecting.

There are two ways to calculate whether the structure will protect the entire house from lightning strikes:

- The easiest way is to draw an imaginary line at an angle of 450 from the highest point of the lightning rod to the ground.Everything inside the circle described by this line is protected.

- For a more accurate calculation, we use the formula for the protection radius R = 1.73*h, where h is the height of the lightning rod.

Installation of lightning rod

Work on the installation of the protective circuit begins with the installation of the receiving part. The sequence of operations here directly depends on the features of the roof structure, so here I will give only the most general tips.

Let's start with the bar model:

- To capture the discharges, we use either a metal rod with a diameter of 12 mm or more, or a pipe with a cross section of 15–20 mm. You can also buy ready-made lightning protection kits from J Propster, GALMAR, etc.

- First, we install the bed, which will be used as a base. The role of the bed can be high chimney, antenna mast, etc. It is also possible to make a separate frame from a wooden beam or a profile pipe, firmly fixing it on the ridge and strengthening it with braces / stretch marks.

- We fix the metal rod to the frame either by welding or using clamps. Lightning rods from a corner or profiled pipe can be bolted.

The cable version is done like this:

- We install vertical supports on the edges of the ridge. For a private house, a height of 1 m is sufficient. The optimal support pitch is approximately 1.5 m, which minimizes sagging and windage of the cable.

- If the supports are made of wood, then the catching cable can be attached to them without additional devices. . We purchase ceramic insulators for steel poles.

- Between the supports we pull a cable with a diameter of 6 mm.

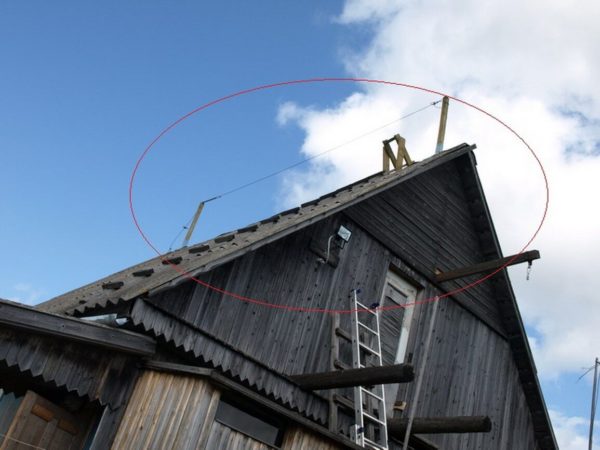

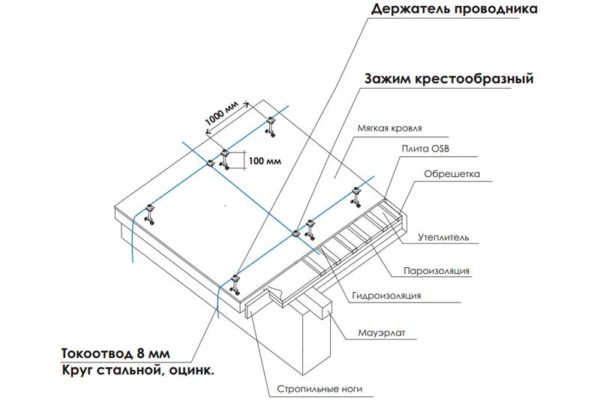

The lightning protection mesh is mounted taking into account the following requirements:

- The optimal conductor thickness is 6 mm or more.

- At the intersections, the conductors are either welded or connected with special couplings.

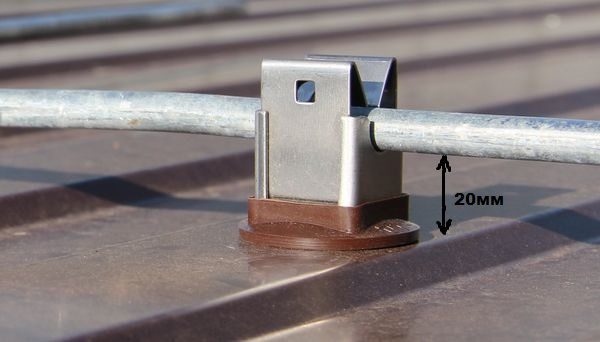

- There must be a gap of at least 20 mm between the roof and the catching elements. To do this, the grid is laid on special stands with a dielectric base.

Where the mesh is in contact with combustible materials, the gap must be increased to 15 - 20 cm.

After mounting any lightning rod, it is necessary to check its electrical resistance. The maximum value of this parameter is 10 ohms.

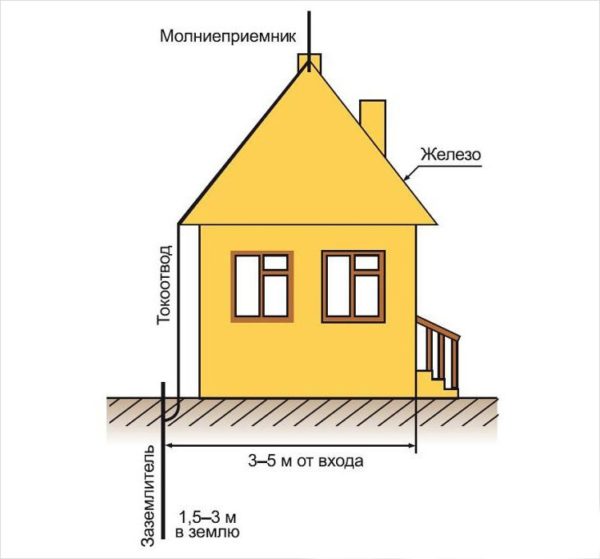

Conductor line

The next element, which includes the lightning protection circuit of the house, is the down conductor:

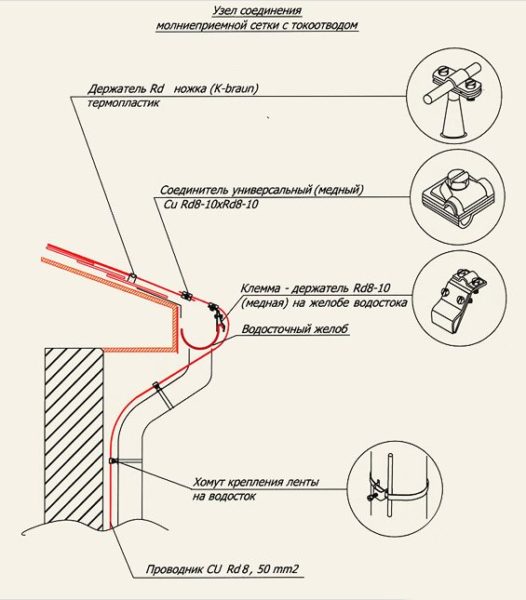

- The basis of the down conductor is a wire with a diameter of at least 6 mm. The optimum wire cross-section depends on the material and is at least 16 mm2 for copper, 25 mm2 for aluminum or 50 mm2 for steel conductor.

- The current-carrying wire can be connected to the lightning arrestor either by welding or by bolting. From my point of view, the most reliable fastening will be a clamping sleeve, which provides both a strong fixation and reliable contact.

- The conductor is lowered from the roof to the ground, fixing it on the walls or downpipes. For the simplest fixation, staples are used, but today special fasteners can be purchased instead of them.

If the roof is large, then the conductive wires should go down every 25 meters.

- When laying a conductive wire on the walls and roof of the house, all turns must be drawn in the form of smooth arcs. This is done to minimize the risk of a spark discharge.

- In the manufacture of this element from a metal subject to corrosion, it is necessary to protect the conductor from moisture. A regular corrugated cable channel is fine.

When designing the current duct laying route, it is necessary to take into account the existing contradictions. On the one hand, all regulations require that the conductor be as short as possible. On the other hand, it is necessary to lay the contour to places where the risk of lightning strikes is highest - along gables, dormer windows, roof ledges, etc.

Ground loop

Grounding must be installed at least 5 m from the house, paths, playgrounds, pens for livestock and poultry, etc. To install the circuit, it is advisable to choose a site with constantly wet soil, since current disposal will not be as effective in dry land.

For mounting the circuit, you can purchase a special set of metal tubes and connecting elements. But such a kit is expensive, therefore, suitable conductors are usually used for work.

This do-it-yourself lightning protection element at home is mounted as follows:

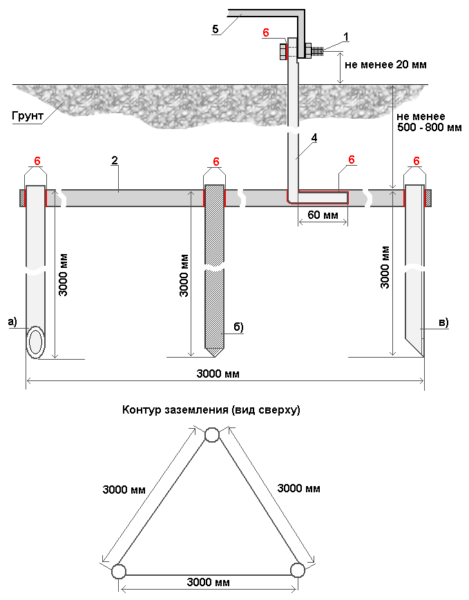

- On the selected site, we outline the contours of the structure in the form of an equilateral triangle with a side length of 1.3 to 3 m.

- By marking, we dig trenches about 30 cm wide and 80 - 120 cm deep.

- In the corners we hammer in ground electrodes - steel corners 40x40 mm or metal tubes with a wall of at least 3.5 mm.For the convenience of driving, we cut off one end of the ground electrode obliquely, and pile a metal plate on the other.

- The driving depth is from 1.5 to 2.5 m, while at least 20 cm of a corner or pipe must remain above the bottom of the trench.

- With steel strips we connect the upper parts of the ground electrodes into an equilateral triangle. Instead of steel strips, you can use copper wire with a thickness of at least 8-10 mm, screwed to the bolts installed in the electrodes. To avoid corrosion, the bolts at the attachment point are abundantly lubricated with grease.

- To connect to the current-carrying cable, we weld a steel strip to the triangle, which we bring to the surface.

- We fill the entire metal structure with salt (this will increase its efficiency by changing the composition of the soil solution) and fill the trench with earth.

- To the metal strip brought to the surface, we fasten the current-conducting wire from the lightning rod with a bolted connection or a coupling. You can also connect the ground wire from the electrical panel here.

The ground loop will provide effective neutralization of even a fairly strong discharge. However, during a thunderstorm, you should not be closer than 4 m from the grounding point, otherwise there is a risk of falling under step voltage.

System Care

In order for lightning protection in a private house to work effectively and without failures, it is necessary to perform the simplest preventive operations:

- Every year, before the start of the thunderstorm season, we inspect all elements of the system. If necessary, we repair, replace or treat with anti-corrosion compounds.

- Once every three years, we carry out a full cycle of preventive maintenance: we check the connections, if necessary, tighten the couplings to restore contact. We clean surfaces from oxides. We carry out measurements of the electrical resistance of the circuits.

- Once every five to seven years, we open the underground part of the ground loop. We inspect the parts to identify areas damaged by corrosion. If the pipe, fitting or strip is more than 1/3 rusted, the element must be replaced.

Conclusion

Grounding and lightning protection are two interrelated components that provide fire protection for a building. The technology of protective circuit devices is described in detail above and shown in the video in this article. In addition, you can get advice on installing lightning protection by asking a question in the comments.

Did the article help you?