How often do we think that construction works are subject only to masters, professionals in their field. And sometimes we pay them dearly for what we could have done ourselves. This article is devoted to a detailed consideration of the installation of a soft roof. Do-it-yourself soft roof, is it real or not?

How often do we think that construction works are subject only to masters, professionals in their field. And sometimes we pay them dearly for what we could have done ourselves. This article is devoted to a detailed consideration of the installation of a soft roof. Do-it-yourself soft roof, is it real or not?

Where to begin? How to make a soft roof reliable and durable on your own? This article will help you answer these and many other questions related to the installation of a soft roof.

So, you decided to start installing a soft roof with your own hands - this is worthy of respect. To install a soft roof, you do not need a special tool, equipment for installation, as well as equipment for repairing a soft roof, can be found in every owner:

- hammer;

- hacksaw;

- sharp roofing knife;

- putty knife;

- measuring tape;

- mastic "Fixer" and a gun for her;

- bucket;

- pencil;

- a skein of chalk rope;

- nails;

- building hair dryer;

- trowel, it will help distribute the adhesive mixture over the bitumen.

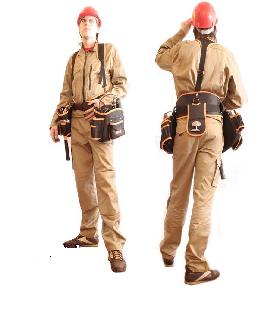

Advice! When starting installation, prepare all the necessary tools and think over its convenient location. The best option is to purchase a special tool belt, it allows you to keep all the tools at hand and saves a lot of time.

Let's say you bought a material and prepared a tool. Next, we will tell you about how to lay a soft roof, and avoid mistakes. Pay attention to the surface on which you will lay the soft roof.

It should be as clean, dry, even and resistant to deflection as possible. The best surface for laying a soft roof is OSB or moisture resistant plywood.

Mistakes in the choice of material for the roof base, or unevenness, can lead to a significant reduction in the life of the roof.

In this case, it may be necessary to repair the soft roof SNiP (that is, repair in accordance with building codes and regulations).

Advice! Pay attention to the angle of inclination of the surface on which you will lay the soft roof. The angle of inclination of the surface should not be less than 11 degrees, in order to avoid additional load, when laying on a surface located at a lower angle, laying is carried out in several layers. The number of coating layers is determined by the angle of inclination of the roof base.

After preparing a solid roof base, you need to check its geometry. Compare the length, width, diagonal size and flatness of the slope.

Eaves overhang, it is better to further strengthen the metal strips. They need to be laid with ribs on the edge of a solid base, secured with nails in a checkerboard pattern.

We lay the planks with an overlap, the minimum overlap is -3 cm. Next, you need to put the valley carpet in the valley and on the cornice overhangs, regardless of the roof slope. If the slope is less than 12 degrees, it is necessary to lay the valley carpet over the entire plane of the roof.

If the slope of the roof is more than 12 degrees, we lay the valley carpet with a width of 1 m. 50 cm for each slope. Horizontal overlaps when laying the valley carpet are 10 cm, vertical -15 cm.

It is advisable to additionally fix the lining carpet around the perimeter with nails with a galvanized hat.

To protect the side parts of the roof from moisture and wind damage, gable strips are needed. The edge of the gable plank should lie on the edge of the roof base.

Fronton strips are fastened with nails in a checkerboard pattern. The overlaps of the planks in the corners must be at least 3 cm.

Next, we need to mark the base of the roof with chalk rope. The markup is applied in the form of a grid. The step of horizontal lines should be equal to 5 rows of tiles, the step of vertical lines -1 m. Marking lines serve as a guide when laying soft tiles, and help to align it horizontally and vertically.

The modern building materials market offers a variety of coatings for soft roofing. The installation technology of various materials may differ, but the general recommendation for all types of soft roofs is to lay it in a warm, preferably hot season. The design of the roof is also important when installing a flexible roof.

Regardless of the material used, the entire process of installing a flexible roof is divided into 3 main stages:

- Installation of the first sheet and cornice row.

- Fastening the remaining rows.

- Installation of "ridge" sheets.

So, let's proceed to the installation of the starting strip. Usually, a special ridge-cornice strip or a regular strip with cut petals is used as the first strip.

We remove the protective film from the back of the ridge-cornice tiles and fasten it along the cornice strip with an indent of 1.5 cm from the edge. Be sure to fasten each sheet of tiles with nails in the corners.

When laying ordinary tiles, it must be taken into account that its shade in different packs may differ, that is, you need to take sheets alternately from several open packs.

The first row retreats 1-1.5 cm from the starting strip. In the case of a roof slope of less than 45 degrees, we fasten each strip with 4 nails, but if the roof slope is more than 45 degrees, add 2 more nails to fasten the tile sheet in the center.

At the same time, it is important that the nail head presses the coating, and does not violate its integrity.

On the pediment, you need to cut the tiles 1 cm to the edge of the end plank. At the same time, the upper outer corners of the sheets are cut off to repel rainwater. The edge of the tile with a width of 10 cm is glued with bituminous mastic.

When a tile adjoins a pipe or ledge. The junction is covered with a pattern from the valley carpet and glued with bituminous mastic.

When the last row of the coating is laid, we proceed to the installation of the ridge row. When making the ridge, the tile sheet is cut into 3 equal parts, heated at the bend with a building hair dryer, and fastened with nails to the ridge, placing the nails along the axial line of the tile.

The overlap is the same as when laying ordinary tiles.

The material for mounting a soft roof weighs a little, so there will be no problems with lifting sheets onto a roof with a large slope.

Despite the fact that the soft roof device has excellent waterproofing properties, experts recommend additionally using a rolled self-adhesive substrate impregnated with bitumen.

After all, additional waterproofing of a soft roof is a guarantee of its long-term operation. A mandatory step in the installation of any roof, including soft, is the laying of insulation.

Advice! When laying insulation under soft tiles, avoid steam. With the ingress and concentration of steam, the thermal insulation properties of the insulation can be significantly reduced.

Remember that the unscrupulous work of the craftsmen, or an independent violation of the technology for installing a soft roof, can lead to the formation of air or water cushions under the roof, or a violation of the integrity of the roof.

In this case, we recommend that you repair the soft roof with your own hands.

Soft roof repair includes replacement of damaged areas of the coating, installation of a two-layer roofing carpet in areas of frequent damage, the use of additional parapets or aprons made of galvanized steel to protect vulnerable areas.

Summing up

If you do not know how to lay a soft roof, start by installing a cornice row. To begin, lay the first sheet along the eaves, 1-2 centimeters above the cornice inflection.

Remove the protective film from the sheet first. Next, lay the remaining rows butt joint to the previous ones.

Don't forget to soft top fasten the sheets with nails in the places of perforation.For easy gluing, use mastic for soft roofing. It must be selected in accordance with the material that you use for soft roofing.

Thank you for reading this article. I hope that now you understand how to make a soft roof. And no matter what kind of soft roof you like, you can install it yourself without any problems.

Did the article help you?