At the moment, a fairly wide range of different materials for roofing is presented on the construction market, one of the most popular is galvanized iron for the roof, time-tested and successfully used for several centuries.

At the moment, a fairly wide range of different materials for roofing is presented on the construction market, one of the most popular is galvanized iron for the roof, time-tested and successfully used for several centuries.

The roof made of galvanized iron is characterized by a long service life, high reliability, strength, as well as a rather attractive appearance.

Galvanized steel is by far the most common roofing material, and it gained the most popularity during the initial stage of the building boom due to its main positive characteristics:

- Significantly lower cost than foreign metal tiles;

- Relatively high service life;

- Original design.

In addition, galvanized roofing is an environmentally friendly material that does not harm the environment and human health.

It should also be noted the good reflective properties of the roof, as a result of which the galvanized roof is well protected from overheating under the scorching sun.

This material also has a number of disadvantages, the main of which is the poor quality of sound insulation - hail or rain blows are usually heard indoors even under do-it-yourself hipped roof.

It is also important that the zinc coating is able to provide effective protection of iron for a fairly long period of at least 20-30 years.

Today, many roofs erected in the early nineties require major repairs, which is aggravated by the not always high-quality performance of the zinc coating on them, which causes the appearance of matte gray spots on the roof, indicating corrosion processes.

In this case, it becomes inevitable to perform roof repairs.

Building a galvanized iron roof

Before you cover the roof with galvanized iron, you should talk more about the material itself. It is a sheet iron, which is coated with a zinc coating that increases corrosion resistance.

This coating eventually comes off the surface of the iron, therefore, as an additional protection measure, it is recommended to paint the material even in the early stages of operation.

The main advantages of the material from which the galvanized roof is made are:

- High service life;

- Low cost;

- Ease of installation;

- The ability to manufacture sheets of any required shape and thickness.

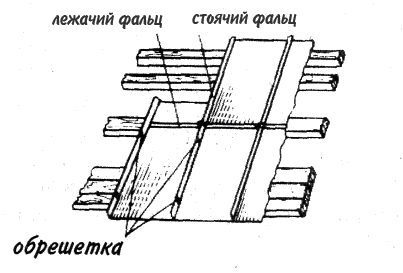

The main use of galvanized iron is the construction of roofs without insulation, made in the form of sheets of roofing material laid on a layer of lathing.

The versatility of this material also lies in the fact that various roofing elements can be cut out of it, such as galvanized roof flashings, valleys, ridge and end trim elements, etc.

Before you cover the roof with galvanizing, you should choose the right board for making the crate.

Most often, an unedged board is used, the thickness of which allows it to withstand the weight of a person working on it, and the length should be two spans between the legs of the rafters of such a design as gable standard roof.

Before making the coating, galvanized iron should be cut into sheets of the required dimensions, and it should also be leveled, eliminating various deflections and significant dents.

Important: you should not nail the boards of the crate close - you need to leave a gap of 10 to 30 centimeters.

Sheets should be laid starting from one of the corners of the roof, moving from the bottom up and leaving a mandatory allowance of 10 to 20 cm for the equipment of the storm system. You can fasten the material either to the lock, or using metal screws, baiting them and screwing them into the crate bars.

Useful: when fastening to self-tapping screws, steel spacers should be used, in addition, it is important to ensure that the sheets overlap by 150 mm.

Fixing roof coverings such as hip roof, the lock has a number of advantages, such as the absence of extra holes that can lead to leaks and material savings, since there is no need to make a horizontal overlap.

Sheets are installed in the following way:

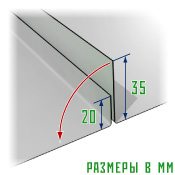

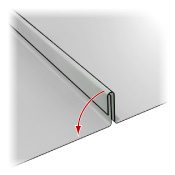

- A sheet of iron is laid on the crate and one of its side edges is folded up so that the width of the resulting folded strip is 2-3 cm.

- The next sheet is folded in the same way, but with a strip width of 3.5-5 cm, and is placed close to the first sheet, after which the protruding part is folded.

- Both strips are bent towards the shorter one.

Important: a mallet should be used to bend the sheets, and a steel hammer is placed under the blows from the back.

This method of connecting sheets allows you to create additional stiffeners, increasing the overall strength of the material. To fix the material on the crate, nails or self-tapping screws screwed into the places of the allowance of the top sheet are used.

Useful: it is recommended to additionally bend the first one around the edge board of the crate protruding by 10-20 cm, and then fix it from the bottom or end part of the board.

Proper care of a galvanized iron roof

In order for the repair of a galvanized roof not to be required for as long as possible, various maintenance work should be carried out literally from the moment of coating, for example, immediately after the construction of the roof, it is desirable to paint it.

When choosing how to paint a galvanized roof, it should be borne in mind that galvanizing enhances the passivity of the iron surface, so you should choose a paint that has sufficient adhesion and elasticity.

Oil and alkyd paints are not suitable in this case, since their interaction with zinc will cause chemical reactions on the surface, as a result of which the oxidized paint will lose its adhesive properties.

This will cause it to peel off rather quickly, as a result of which the coating will become completely unusable within a maximum of one season.

In this regard, a special paint for a galvanized roof, such as acrylic primer-enamel, should be used, the coating of which can serve well for many years.

Their high cost compared to conventional paints pays off by significantly increasing the life of the roof, in addition, it gives the roof a more aesthetic appearance than in the case of oil paints.

Before painting a galvanized roof, you should check the condition of the coating: if rust is present, replace or clean the coating with kerosene, or patch up possible holes.

If the roof has already been painted before, then the old paint must be cleaned off, as well as the accumulated dirt, after which the roof should be washed and degreased.

After it is completely dry, begin to apply paint with a spray gun, roller or fly brush.

Important: for greater effectiveness, it is recommended to apply two or three coats of paint to the roof.

If there are holes or cracks on the surface of the roof, they are soldered using patches made of metal, fiberglass, plastic, etc.:

- With the help of sandpaper, rust and paint are cleaned at the joints of the sheets, after which they are adjusted as tightly as possible to each other.

- Using a brush moistened with zinc chloride, wipe the joints.

- Soldering is done with a powerful soldering iron, after wiping it with ammonia.

- After the joints have cooled, remove excess solder.

Currently, there is a fairly wide range of special sealants and adhesives with which you can close the hole formed in the roof without using a soldering iron, which greatly facilitates roof maintenance.

Epoxy-based automotive putties and putties are the most widely used. When choosing such a tool, you need to make sure that it is sufficiently securely held on galvanized.

In order for a galvanized iron roof to serve for a long time without requiring repair, it is necessary to provide proper care for it during operation, as well as to avoid various mechanical damages, including during its construction.

For fastening sheets, it is recommended to use special self-tapping screws with a silicone gasket that allows you to seal the hole.

It is also very important to paint the constructed roof with a special paint as soon as possible, which will also significantly extend the period of its reliable and efficient service.

Did the article help you?