Roofing galvanized iron has long been used for roofing, as well as for the manufacture of individual elements. Gutters, sockets, gutters made of this metal served their owners for many years.

Currently, roofing iron is also used for exterior decoration of various structural elements. It serves as a reliable protection for the facade of buildings.

Nowadays, galvanized iron roofing is as popular as it was many years ago. The reason for this is the relatively low cost of the material and the ease of work.

At present, roofing iron, which is supplied in rolls, has become more widespread. Such material is easy to transport, it does not require a lot of space, and it is very convenient to carry out installation work.

Advice!

Due to the ability to cut the sheet to the desired length, less material is consumed, which is very convenient.

The resulting iron roof is durable and practical, which are the most important operational factors..

In addition to rolled iron, corrugated roofing iron, intended for roofing, is also on the market.

The types of such material include:

- metal slate;

- corrugated board;

- metal tile.

For their production, anti-corrosion modifying additives are used, with the help of which the performance of the coating is increased..

Thanks to a high-tech process, it becomes possible to create durable metal sheets that practically do not collapse under the influence of aggressive environments, while maintaining their appearance for a long time.

Roofing galvanized iron is sold in all regions of the country, since profiled sheets are used not only for roof devices, but also for creating barriers and wall cladding. Due to its low weight, galvanized iron roofing - GOST, which specifies certain requirements for power loading, is often used as structural elements for reconstructed buildings.

The corrugated board has high strength characteristics, which allows it to be used as an independent load-bearing structure for various structures and buildings.

Your attention!

In addition to excellent performance parameters, profiled sheets have a low cost, which allows you to ennoble your own country house inexpensively and in a short time, because iron sheets can look as attractive as natural tiles.

It should be noted that roofing iron is a universal roofing material that can be mounted on any surface..

Due to the presence of a wide range of colors, great opportunities open up in building design, which allows you to give buildings architectural expressiveness and uniqueness.

As noted earlier, roofing iron is divided into several types and is steel, which is coated on all sides with a layer of zinc for protection.

Before purchasing roofing iron, you need to decide whether you need heat-resistant or with increased resistance to ultraviolet radiation, in addition, there is iron with increased resistance to mechanical damage and aggressive environments.

- Decking.

This material is an iron sheet with a galvanized surface, which is profiled, or, more simply, it is given a wave-like shape to increase the rigidity of the sheets.

Corrugated sheets are produced both with polymer coating and without it. You can buy such galvanized iron roofing in sinus-shaped, trapezoidal and rounded shapes.

Also, profiled sheets have different heights, widths and scope.In order to expand the capabilities of the architect, to create curvilinear products for decorating ridges, cornices and wall corners, roofing profiled iron is made in the form of arches and transversely bent sheets.

- metal tile.

This material is represented by a solid sheet, which occupies one of the leading places among roofing.

This type of profiled sheet has a special polymer coating and transverse stamping, which imitates the pattern of ceramic tiles.

Metal roofing gives a great look to low-rise buildings, temporary structures and small public buildings.

This material has a large range of colors, types of polymer coatings and profile geometry.

The only drawback of a metal tile is that an iron roof made of this material requires the purchase of material from the same manufacturer from which it was purchased earlier for repairs. The reason for this lies in the fact that other manufacturers have significant differences in the shape, size and steps of the profile waves.

How to care for an iron roof?

Serve such roof can average about 50 years and throughout this time it retains a magnificent appearance.

In order for it to serve the specified period and not disturb its owners, it must be properly arranged. It is worth noting that the installation of this material does not require special skills, so you can do it yourself.

Your attention!

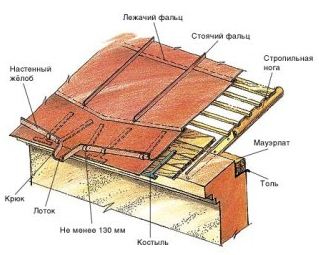

Proper installation is directly related to the roof surface.First, the diagonal roof should be the same size. Secondly, you need to take into account the angle of the roof before proceeding with the installation of the crate.

The smaller the slope, the greater the distance between the boards should be. Thirdly, during installation, you need to take into account the fact that the boards should be in places of overlap and, based on this, calculate the step.

Did the article help you?