The comfort and living conditions in the house largely depend on how well the construction of its roof is completed. This article will talk about how to properly install the profiled sheet on the roof.

The comfort and living conditions in the house largely depend on how well the construction of its roof is completed. This article will talk about how to properly install the profiled sheet on the roof.

The choice of material for covering the roof is very important when building a house, it should be taken as seriously as possible and take into account all the parameters and characteristics of the structure, as well as its appearance.

AND do-it-yourself corrugated roof - optimal solution.

Roof profiled sheeting is becoming more and more widespread recently - a roofing material that has a relatively low cost, while providing a fairly high quality coating, which can also be used for other surfaces besides the roof.

The price of this material depends on its various characteristics, such as the thickness of the steel, the type of coating and the height of the corrugations.

A profiled sheet roof is very popular with developers, not only due to minimal costs with a fairly high-quality end result.

This method of roofing has been used for quite a long time, while the material is constantly being improved: first, manufacturers began to galvanize sheets of corrugated board, then they began to additionally apply an anti-corrosion coating.

To ensure maximum reliability and an attractive appearance, you should carefully choose which profiled sheet will be laid on the roof.

Sheets of corrugated board are also given an original relief by rolling, which can be made in the form of trapezoids or waves and not only improves the overall attractiveness of the roofing, but also allows the coating to withstand more significant external loads.

Such improvements have made it possible to make the profiled sheet on the roof a more reliable and efficient material, the qualities of which are constantly improving.

The service life of a roof covered with galvanized corrugated sheet is over thirty years, and if the corrugated board is coated with polymers, then the service life increases to fifty years.

Laying a profiled sheet on the roof provides a number of advantages over other coating options, such as:

- Low cost of the material;

- Ease and convenience of transportation and installation of the profiled sheet;

- Long service life;

- Environmental Safety;

- Possibility of installation on a heavily thinned crate.

Important: an indisputable advantage of corrugated board is also a wide choice of sheet sizes, due to which the roof of the roof can be covered with a solid profiled sheet, not cut into pieces, while there are no joints on its slopes.

Corrugated roof: installation instructions

In order to correctly and without errors calculate the profiled sheet on the roof, you should accurately measure the length of its slopes, as well as find out the perimeter of the entire building.

The calculation of the required amount of corrugated board is quite laborious, it is recommended to entrust its implementation to qualified specialists, whose participation will help to avoid possible errors and inaccuracies.

Managers of enterprises involved in the supply and sale of profiled sheets can perform accurate calculations using specially developed programs, determining both the total area of the surface covered by the roof and the number of various additional materials and elements, such as fasteners, etc., which will allow the roof to be laid more effective.

Important: the length of profiled sheets for roofing should be chosen proportional to the lengths of the slopes of the covered roof, which will not only greatly facilitate the task of laying roofing material, but also prevent moisture from entering the roof.

Sometimes the question arises of how to cover the roof with a profiled sheet if the length of the roof structure exceeds the length of the purchased material.

In this case, it is best to lay the profiled sheet horizontally, starting from the left or right corner of the bottom row and moving up. In this case, each previous sheet should be partially overlapped by the next one.

When covering the roof with a profiled sheet, an overlap of joints of about 200 millimeters should be left, and to increase the reliability of the structure, the remaining space can be filled with silicone sealant.

Between the top sheet and the heat-insulating layer there should be a space for ventilation - about 40 millimeters. It is recommended to double the number of points for attaching roof sheets to battens or girders.

Even with the most complex shape of the slope, corrugated sheets should be laid strictly parallel to the horizontally aligned cornice, although with such a roof as shed roof of a house made of corrugated board - everything is quite simple.

The overhang of profiled sheets beyond the boundaries of the eaves should not be more than 40 millimeters; additional self-tapping screws are used to fasten adjacent sheets of coating to each other. In addition, it is important to ensure that the polymer or paint layers of the material are not damaged.

Important: with any method of laying corrugated board, you must strictly comply with the requirements and safety standards.

Fastening sheets of corrugated board

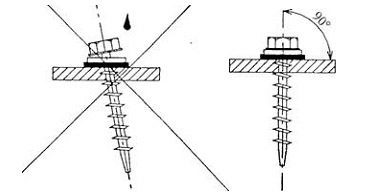

Let's talk about how to fix the profiled sheet on the roof, that is, to the elements of its crate.For this, self-tapping screws equipped with a washer, a drill and a special neoprene gasket are used, the length of which can take a value from 20 to 250 mm, and the diameter is 5-6 millimeters.

The drill at the end of the self-tapping screw allows you to screw it in without pre-preparing the hole. Hexagonal heads of self-tapping screws allow you to screw them in with a screwdriver, which allows you to speed up the execution and improve the quality of laying the profiled sheet.

Sometimes combined rivets are used to fasten profiled sheets to each other. The total number of fasteners when installing sheets of this coating is approximately eight pieces per square meter of corrugated board on straight sections of the roof.

We list the basic rules and requirements for the technique of fastening profiled sheets on the roof:

- It is recommended to fasten the corrugated board at the point of contact of the wave to the wooden elements of the crate, which eliminates the occurrence of a lever at the attachment point and does not require additional efforts when screwing in the self-tapping screw.

- The fastening elements at the longitudinal joints of the profiled sheets should be located at a distance of approximately 500 millimeters from each other.

- It is necessary to fasten all waves of the upper and lower fastening purlins of corrugated sheets.

- The fastening of the profiled sheet is carried out on each purlin. This is especially true on the edge of the roof, located on the side of the wind slats.

- To improve the fit of corrugated sheets to each other, the attachment points of the waves are shifted by a distance of 5 millimeters.

When connecting the outer shelves of the coating sheets, it is recommended to use special combined imported or domestic rivets, the diameter of which is from 3 to 6.5 millimeters.

The connection of various roofing elements using such rivets is carried out using a hand tool used specifically for single-sided riveting.

Useful: to improve the waterproofing characteristics of the roof, when installing the coating, layers of special silicone sealant should be added to all joints.

For tightening self-tapping screws, the most suitable tool is a screwdriver; a drill with a low rotational speed of the cartridge can also be used.

The drill at the end of the self-tapping screw makes it much easier to cover the roof. Specialized stores sell self-tapping screws made specifically for attaching corrugated board to metal battens.

Useful: the maximum accuracy of the installation of profiled sheets is achieved by pre-marking the cores of the holes.

When attaching profiled sheets, nails should not be used - this violates the tightness and allows gusts of wind to violate the integrity of the roofing.

You should also not use a high-speed metal cutting tool for processing corrugated board, since a very high temperature occurs at the processing point, destroying the protective layers of galvanizing and polymerization, which significantly reduces the service life of the coating.

The subtleties of laying the profiled sheet

Before you cover the roof with a profiled sheet, it must be accurately marked. For cross cutting of possible excess material, special piercing shears or reciprocating saws are usually used.

At roof decking installation, whose thickness does not exceed 0.7 mm, wood scaffolds are often used.To avoid damage to the sheets when laying such a coating, it is recommended to use soft shoes.

After completion of work on covering the roof with corrugated board, the roof should be cleaned of debris and metal shavings. For additional protection against corrosion, profiled sheets are recommended to be additionally coated with a special compound in places of minor damage, scratches, etc.

After two or three months after laying, the self-tapping screws should be additionally tightened, which could loosen a little during this time.

Did the article help you?