The construction and insulation of the roof is the final stage of any construction, including the construction of a bath. This article will talk about how the roof of the bath is built with your own hands, what material it is covered with, and what requirements should be observed during its construction.

The construction and insulation of the roof is the final stage of any construction, including the construction of a bath. This article will talk about how the roof of the bath is built with your own hands, what material it is covered with, and what requirements should be observed during its construction.

The shape and design of the roof depends on the type of building on which it is erected.

The roof of a bathhouse differs from the roof of a residential building in its lighter weight, and various architectural subtleties depend on different building codes, which are related to the dimensions of the bathhouse, the materials used in the construction of the walls and laying the foundation, as well as the characteristics of the area where the construction is being carried out.

When thinking about how to make a bath roof, you should consider a number of recommendations when choosing its type:

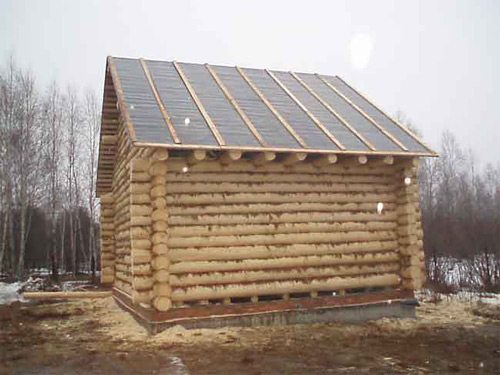

- If the bathhouse is built in the form of a separate building, then a gable roof is erected on the bathhouse with your own hands, which ensures maximum reliability and significant savings in building materials.

- In areas with heavy rainfall, the slope of the roof should be about 45 degrees, as a result of which snow masses do not accumulate on the roof structure.

- In the steppe and forest-steppe regions, where the bathhouse is located in an open area, the roof in the bathhouse is erected with a slight angle of inclination to avoid damage as a result of strong gusts of wind.

- In the event that the bathhouse is an extension to a building, for example, a residential building, a do-it-yourself roof for a bathhouse can be erected. The angle of its inclination is selected depending on the materials used for covering the roof in the range from 50 to 60 °.

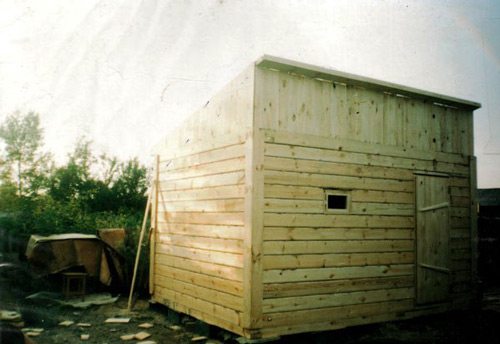

Gable roof - the most common version of the bath roof

In order to know how to properly make a roof in a bath, it should be borne in mind that the simplest structures in terms of installation are also considered the most reliable.

Despite the originality and beauty of multi-pitched roofs of an intricate shape, the process of their construction is quite laborious and requires large expenditures of building materials.

Types of roofs for a bath

Both single and double pitched roof differ in their design on roofs with an attic and roofs without an attic.

The manufacture of the roof of a bathhouse with an attic space begins with the manufacture of the attic floor, after which the roof itself is already being erected.

If this space is absent, then the ceiling and the roof of the bath are combined, which is often made lean-to in the absence of an attic.

In order to make the right decision on how to make a roof in a bath, you should study in more detail the main features of both types of bath roof:

- The roof of the bathhouse with an attic room looks more attractive and provides an original appearance of the bathhouse. In addition, it has good thermal insulation characteristics during cold weather, since after the shelter is equipped, a ceiling is erected to protect it from the effects of precipitation during construction.

- If we build a bath roof without an attic, such a bath is more suitable for use in the summer.

- This roof option is more economical in terms of labor and material costs, and can also be used for other purposes, such as drying fruits and vegetables, sunbathing, etc.

Currently, a wide range of materials is offered that can be used to cover the roof of a bath - ondulin (euro slate), metal, tiles, etc.

Depending on the material chosen, you should also choose the angle of inclination of the roof, which is from 15 to 27 ° for a metal roof covering, 27 degrees for slate, from 3 to 15 ° - when using a roll material that has a low weight.

If the roof of the bath is equipped without an attic, the slope angle can be chosen quite small - within 10 °.

There is another original version of how to cover the roof of a bath, which is not widely popular in our country, but widespread in many foreign countries - this is the covering of the roof of a bath with turf, known since ancient times.

The easiest way to lay such a "green" coating is as follows:

- On top of the flooring, the roof of the bath is waterproofed with several layers of material;

- Two layers of turf are laid on top of the waterproofing, the bottom one is laid up with the roots, and the top one is laid with the roots down.

Such a roof should be given a slope angle of 10 to 15°. Such a roof looks very aesthetically pleasing, but do not forget that, like a regular lawn, a “green” roof requires special care.

Therefore, choosing this option for roofing, you should also provide for the availability of free time to maintain its "blooming" state.

Bath roof erection

There are a fairly large number of both printed publications and materials on the Internet about how to build a bath roof. Let's talk briefly about the main stages of the construction of a bath roof.

The design of the roof of the bath consists of two parts:

- The bearing part, which includes elements such as girders, rafters, etc.;

- Roofing, which includes a wooden crate, a special coating, as well as various insulating layers to protect the roof from moisture, heat and other negative influences.

The assembly of the truss truss can be performed both on the ground and directly on the log cabin of the bath, but on the ground the work is greatly simplified.

The truss truss is made of several parts:

- Rafter leg, which is a board, the length of which is 2.8 meters, and the section is 100x40 mm;

- The base is in the form of an edged board 4.40 meters long and 100x40 (50) mm in section;

- The crossbar is an edged board that gives additional rigidity to the structure, which is located 50 centimeters under the junction of the contact of the legs of the rafters.

Useful: the boards intended for the roof structure are cut at an angle of 40 ° and fastened together with screws. Sheathing of roof trusses can be both horizontal and vertical, it is easier to perform it on the ground.

After the assembly is completed, the resulting structure is installed on top of the walls of the bath and the process of manufacturing the crate begins, which, depending on the material used to cover the roof, can be done in a run or in a solid one.

When using rolled roofing material, a continuous crate is made of boards with a thickness of at least 2 cm, while the longer the material, the more durable and reliable the bath roof frame is obtained by reducing the number of seams at the joints.

Useful: it is recommended to place the butt joints not at the same level, for which boards of different lengths are used.

The construction of the bath roof is carried out in the following way:

- On the upper piping of the walls, beams are laid that serve as a support for the roof structure. If the project provides for an attic space, then the overlapping beams are fixed in the sockets. During the laying process, the horizontal fastening of the beams should be carefully controlled. If they protrude beyond the boundaries of the walls to a distance exceeding 50 cm, an additional pillar-support is installed under the beams.

- On the supporting parts, rafters made in the form of boards, beams or logs are installed at a distance of at least 1 meter from each other. The rafters are fastened with wooden plates or metal brackets.

- When covering the roof with rolled material, it is necessary to first make a solid wood flooring on its structure. If tiles or slate are planned for covering, then a crate is made of boards or timber.

- The roof ridge is closed with asbestos-cement blanks or galvanized metal.

- The gables of the bath roof are sewn up with boards, siding or clapboard to the taste of the developer.

- If there is an attic under the roof, then openings for doors and windows are left at the ends of the roof, which, depending on the angle of the roof, can be located both on one side and on different sides. With a gentle slope of the roof, it is recommended to place the window and the door on different ends of the roof.

Bath roof covering

Let us consider in more detail the procedure for covering the roof of a bath using the example of slate:

- The first step is the laying of roofing material, and the side part of its first strip is a guideline for laying slate. When cutting roofing material, in order to avoid various shortcomings associated with the length of the slope, an allowance of 10-15 centimeters should be left. Laying should be done carefully and with high quality, no waves should be allowed on the surface of the already laid material.

- Next, the edges of the roofing material protruding beyond the boundaries of the crate are marked and cut off according to the mark. To prevent the first sheet from being blown away by the wind, it is fastened with special buttons.

- Each subsequent strip is laid on the previous one with an overlap of 8-10 centimeters.

- Slate is usually laid in one and a half sheets in relation to the height of the slope of the bath roof, and in order to speed up the laying process, it is recommended to cut the halves of the sheets in advance.

- Skates are either made by hand from two boards or galvanized iron, or purchased ready-made in a specialized store.

Bath roof insulation

Bath roof insulation can be done in several ways: roof insulation can be laid between rafters, on rafters or under them.

The first option is the least laborious, but when using all three methods, the insulation should be laid closely, avoiding the formation of cracks at the joints of the material with pipes, walls and other bath structures.

Care should also be taken to ensure that the thickness of the air gap between the waterproofing and heat-insulating coating is at least two centimeters.

It is also very important to ensure that sagging of the waterproofing material is not allowed, which ensures more efficient ventilation by air currents.

If the design of the roof of the bath is flatter, ventilation can also be improved by building up the rafters with bars, or by laying insulation separately under and between the rafters.

Currently, manufacturers offer a wide range of ready-made modern waterproofing systems, which consist of panels protected from moisture with good thermal insulation.

The use of such systems makes it unnecessary to lay waterproofing under the roof, which automatically excludes one level of air circulation.

When laying ready-made waterproofing systems, an important point is the installation of a vapor barrier layer on the inside.

Insulation can be placed below or above the details of the rafter system, while joining the rebate of individual elements.

It should also be borne in mind that laying the material under the rafters reduces the available attic space, so it is recommended to lay the insulation above the bars.

This allows the elements of the roof structure to remain indoors, providing them with protection from external influences in the form of precipitation and temperature changes.

The remaining open rafters can be used as an additional decoration element of the attic space.

Bathroom ceiling options

The last step in the construction of a bath roof is the choice of a ceiling option. The ceiling can be hemmed with building materials or made by the flooring method. Before choosing the type of ceiling overlap, you should familiarize yourself with both methods in more detail.

When hemming the ceiling from below with boards, an additional layer of vapor barrier material is required. To date, special materials for baths are commercially available that can withstand temperatures in excess of 100 °.

A layer of environmentally friendly mineral wool is laid on top of the vapor barrier as a heat-insulating material.

Another way is to lay a layer of vapor barrier on the draft ceiling from below, after which the wagon board is fixed as a finishing material. A diffusion membrane is laid on top, on top of which a layer of insulation is placed.

The ceiling made by the flooring method is laid along the upper trim of the walls of the bath, while foil, roofing material, roofing felt, a layer of clay can serve as vapor barriers, and both finished products and sawdust, peat, shavings, dry leaves, etc. can serve as insulation.

Proper and consistent do-it-yourself work on the construction of all the structural elements of the bath, which includes the roof, will allow it to serve for a long time and efficiently, allowing you to subsequently receive internal satisfaction from the quality work done.

A competent approach to the study of the material also makes it possible to significantly simplify the process of building a bath and save a significant amount on inviting third-party specialists.

Did the article help you?