Hello. This time I will tell you about how to make a sloping roof on a country house. The topic will be of interest to those readers who plan to build a roof for the construction of an attic in the attic. Based on the results of familiarization with the proposed material, you will have a general idea of how the calculation of the roofing system is performed, and what is the installation technology.

Calculation of the truss structure

An increasing number of country houses are being built using an attic as an alternative to the second floor. The advantages of such a solution are obvious, since you get not only a roof as a barrier system, but also a full-fledged living space, which, with proper arrangement, will be suitable for all-season operation.

An important advantage of the construction of a sloping roof, in comparison with the capital second floor, is the affordable price and short deadlines for the construction work. But, you need to remember that these advantages will only be possible if the roof is properly designed, taking into account the dimensions of the publication and the loads that will be placed on it.

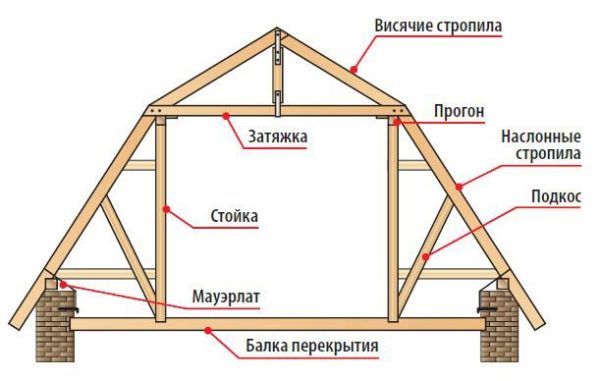

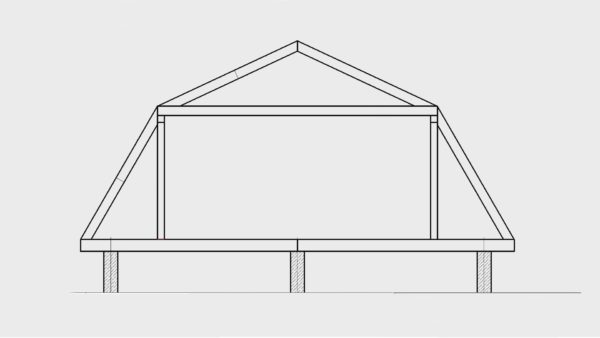

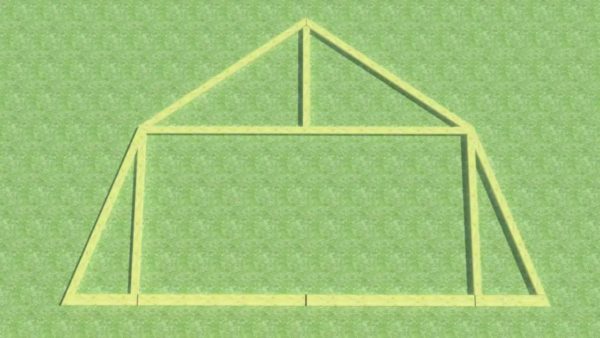

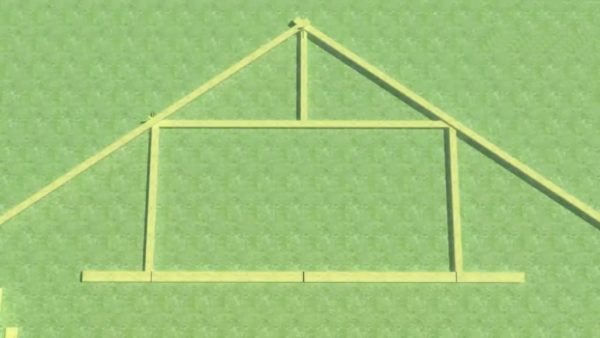

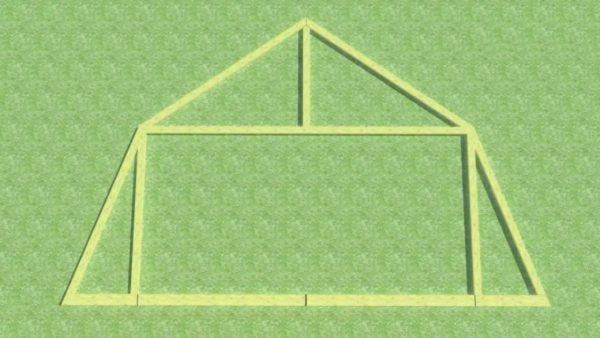

In the figure you can see the traditional mansard roof scheme in section from the gable side. In fact, the entire structure is a prefabricated spatial frame, consisting of rafters, floor beams, a certain number of vertical posts and horizontal struts - puffs.

Such a scheme is popular because of the ease of assembly, and then I will talk in detail about what the instructions for its implementation are.

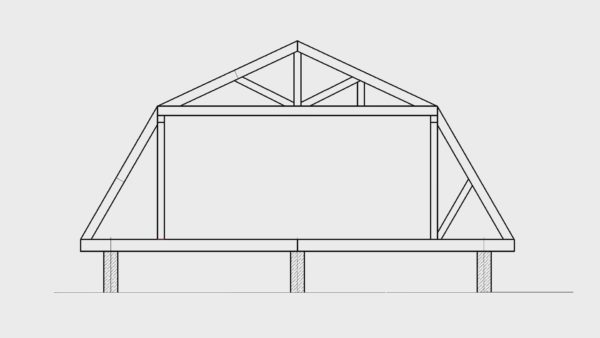

The simple scheme of the roofing system can be reinforced with additional diagonal struts - struts, as shown in the figure. Such measures are mandatory if the width of the attic space according to the project exceeds 6 meters.

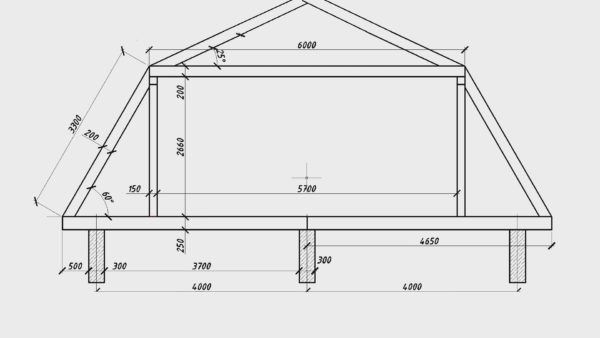

In this figure, you can see a diagram of an attic room with already calculated standard sizes. Please note that puffs and floor beams are made of standard timber with a maximum size of 6 meters. Therefore, you can make a sloping roof without using struts.

The width of the room with a puff length of 6 meters will be 5.7 meters. This is more than enough for rooms intended for temporary residence (bedroom, office, children's room, etc.).

The height in rooms for temporary residence according to the standard should be at least 2.1 meters. In the diagram, this distance is 2.66 meters, which would be enough for a full-fledged residential living room or similar premises.

In the proposed scheme, the rafter legs have the same length of 3.3 meters before and after the break. The same length was not chosen by chance, since it will be easier to order roofing material later. In addition, such roofs look more harmonious than options where the leg at the top and bottom of the fracture has a different length.

The angle of inclination of the slopes relative to the attic ceiling beam is made at least 30 °.

We got acquainted with the basic laws of calculating the truss system, now we will learn how to make a sloping roof with our own hands.

Construction technology

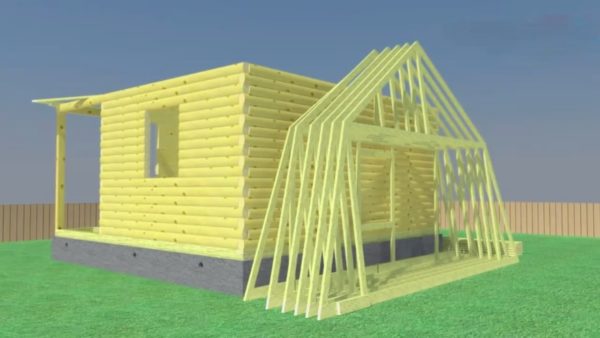

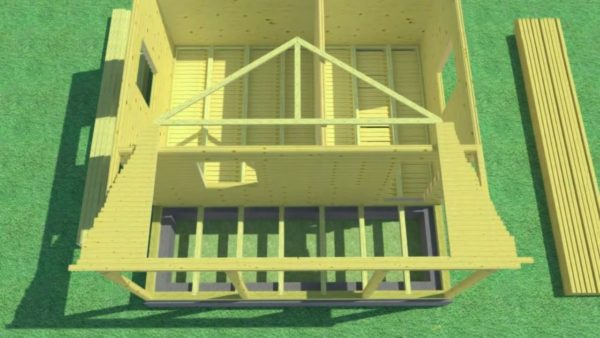

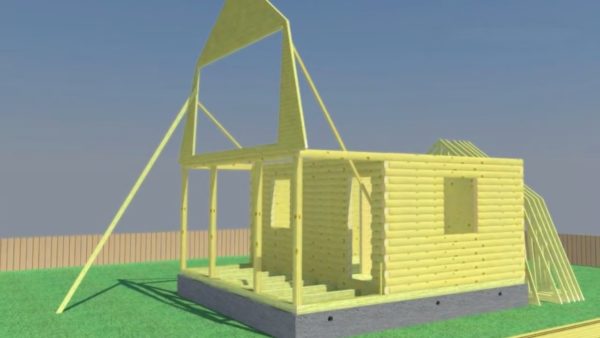

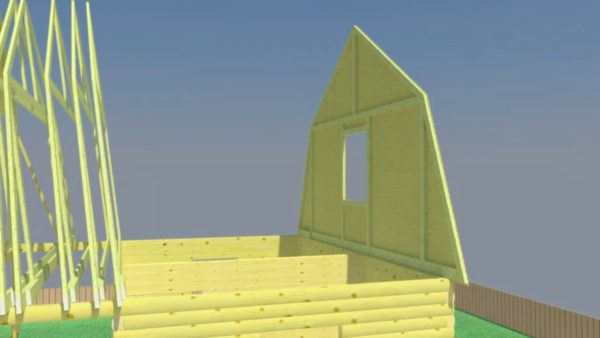

Consider the technology of a sloping roof using the example of building a house from profiled timber according to the PD-010 project.

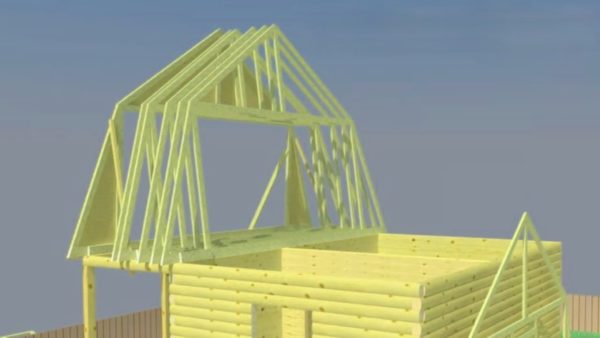

Manufacturing of roof trusses

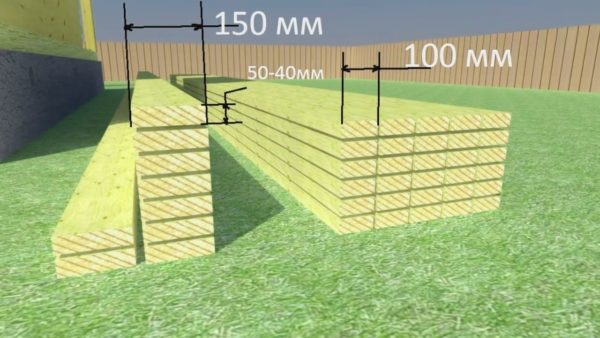

The main material for the manufacture of the truss system is:

- Bar 100 × 50 mm for assembling the frame part

- Bar 150 × 50 mm for assembling the base of the truss system.

The listed materials have a standard length of 6 meters.

I would like to immediately draw your attention to the fact that the proposed dimensions, with the exception of the thickness of the beams, are provided as an example and should be recalculated in accordance with the dimensions of the construction site on which the construction of the roofing system is supposed

.

Assembly instructions for the truss system are as follows:

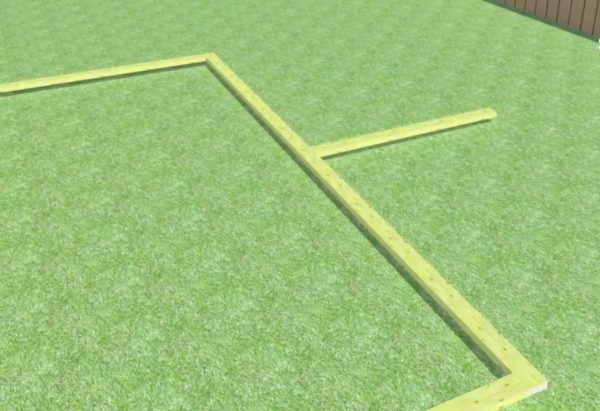

- We prepare materials for the assembly of the base;

In our example, the actual number of roof trusses is at least 7 pieces, so that the distance between them does not exceed 0.8-1 m

.

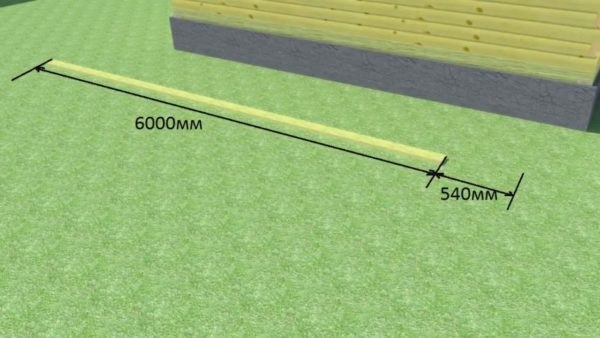

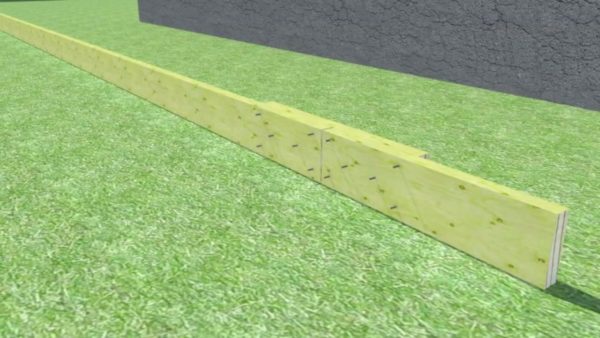

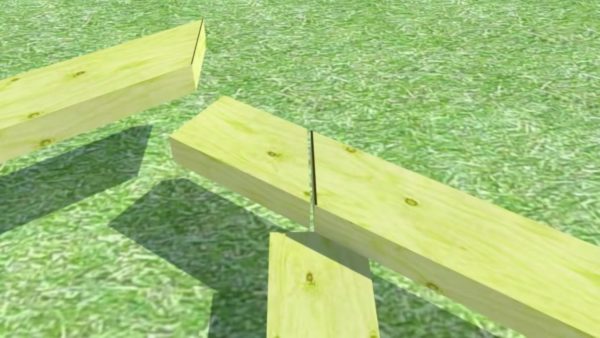

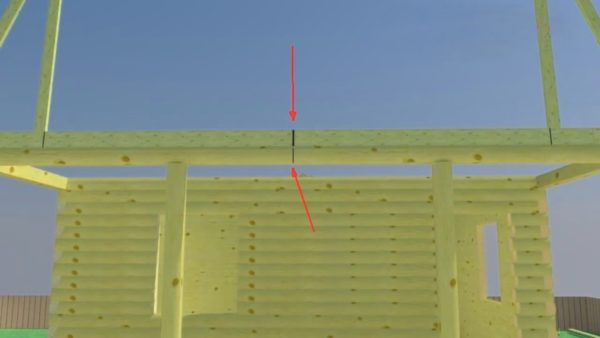

- We increase the bar in length so that it is enough for the corner cornices;

As you can see in the diagram, the standard beam length is not enough, therefore:

- We measure the missing piece of the bar and cut off 2 identical pieces;

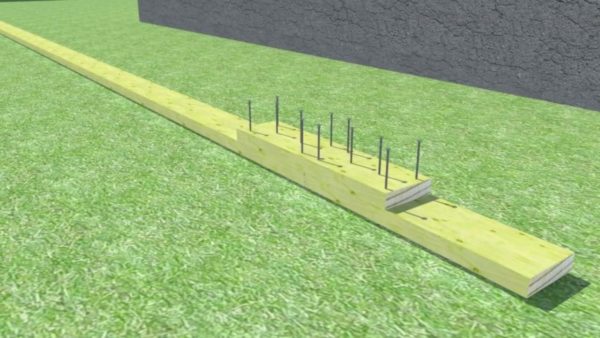

- We apply one prepared piece close to the main part, and put a second (binding) bar on top and fix the structure with nails 150 mm long in an amount of at least 10 pieces;

- We turn the assembled structure over and bend the sharp ends of the nails.

- Similarly, we prepare 7 such bars according to the number of floor beams;

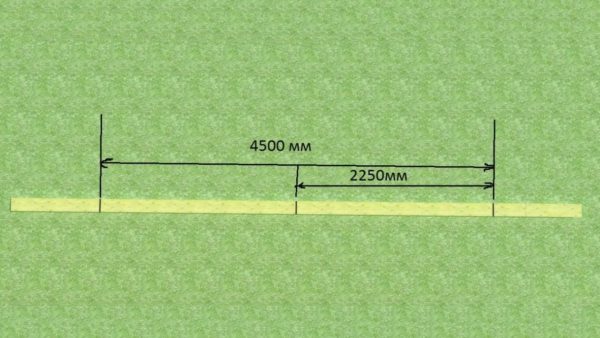

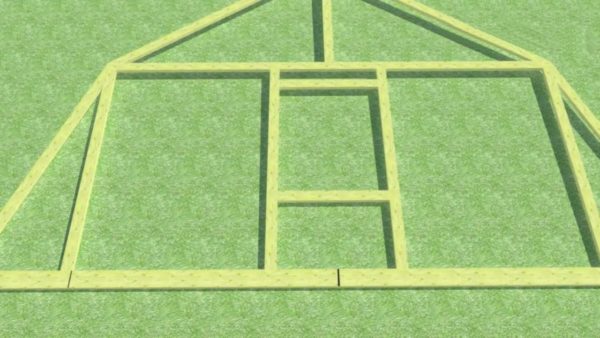

- We mark each of the prepared bars as shown in the figure, that is, we find the middle, and from it we mark 2250 mm on both sides;

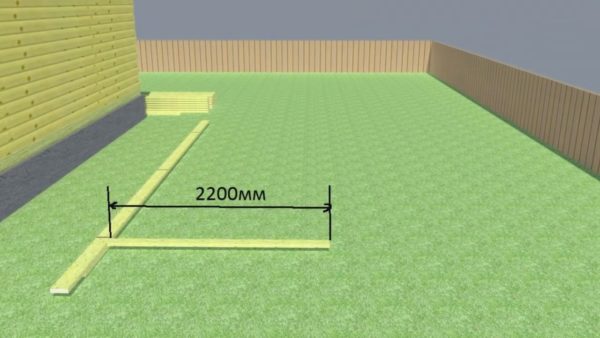

- For each of the 7 prepared floor beams, we cut two beams 100 × 50 mm 2200 mm long (this length is equal to the height of the attic ceiling);

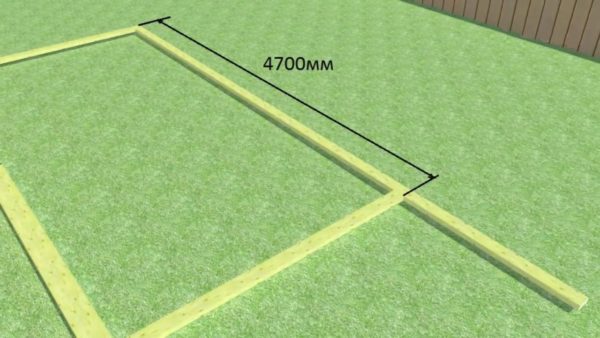

- We prepare a beam 100 × 50 mm for tightening, on which there will be an attic ceiling (length is 4500 mm + two thicknesses of vertical bars = 4700 mm);

- We assemble 7 identical designs from previously prepared parts;

In order to ensure optimal strength of the truss system, the connection of the beam is performed with nails 150 mm long in combination with corner metal plates on a through bolted connection. If we use corner fasteners, we place them on the inside, where the lining will not be subsequently installed.

- On the puff, mark the middle;

- From the marked center, as shown in the figure, we fix a perpendicular bar 100 × 50 mm;

The length of the perpendicular bar must be at least 1.5 meters. The longer this bar is, the greater will be the angle of the roof slope. Fastening is carried out with the obligatory use of corner fasteners

.

- Similarly, we fasten the vertical racks on all seven structures;

- On a vertical stand from the end to the width, mark the middle;

- From the middle we try on the rafter legs so that they pass through the corners of the proposed attic ceiling;

- We mark the adjoining of the bars on the ridge line as shown in the figure and cut off according to the marks made;

- On the line of junction of the rafter legs to the puff, we also make markings so that the ramp passes through the corner;

- According to the markup, we cut off the inclined beam so that it lies with the entire plane on the junction of the vertical rack and the ceiling beam;

- At the level of the ridge, in accordance with the ends of the rafter legs, we mark and cut the vertical beam on which they converge;

- We connect all three elements with a nail connection or with the help of metal corners and self-tapping screws;

- Next, with our own hands we collect the adjunctions of the rafter legs and the ceiling beam;

- Now we try on the bars from the attic ceiling line to the attic floor line;

- We cut the bars so that at the top point they adjoin the vertical stand with a side cut;

- In the lower part, we cut the rafter legs so that they retract into the floor beam;

Thus, when installing the roof slope line, only the rafter leg is cut, while we do not cut the puff and the floor beam

.

- We connect all the prepared parts together;

- Similarly, we assemble 7 identical structures and on this the trusses can be considered ready.

Preparing roof trusses for window installation

Windows can be provided in the attic room. How to prepare roof trusses for installation of frames?

From the seven manufactured trusses, we select two structures that will be installed from one and the other pediment. During installation, these truss trusses will be positioned so that the bundle that we used when building up the timber at the base looked inside the attic, otherwise there will be problems with the pediment sheathing.

Now we cut two beams with a section of 100 × 50 mm and fasten them perpendicular to the line of the ceiling and the floor of the attic at a distance from each other that will equal the width of the window frame + a gap of 15 mm on each side.

After the vertical beams are prepared and installed, we cut horizontal jumpers from the same bar, which will be located along the upper and lower edges of the window frame. We install horizontal jumpers at the distance from each other, which will be equal to the height of the frame.

The installation height of the window can be chosen arbitrarily, but according to the standard, 850-900 mm must be maintained from the floor line to the lower edge of the frame.

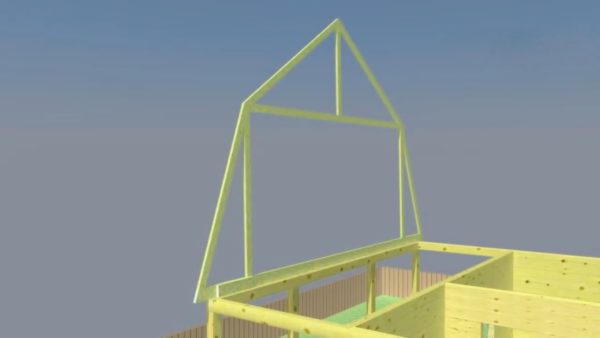

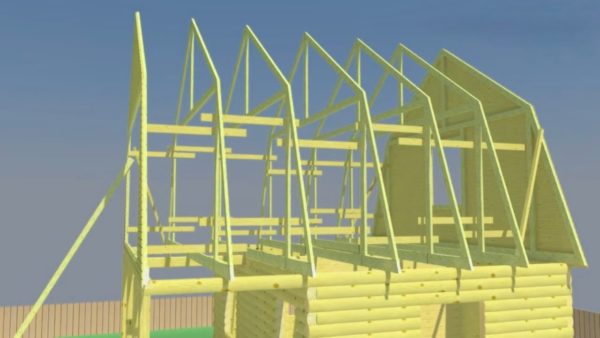

Assembling the truss structure

Before proceeding with the assembly, we raise the previously prepared rafters up in the order in which they will be located. That is, those rafters that will be located on the side of the gables, we unfold the place of the bundle inside the attic.

The order of the intermediate rafters is unimportant.

Also at this stage, you will need a wooden lining for filing celestials (cornices).To mount the lining, we stock up on self-tapping screws 30 mm long in the amount of 2-3 pieces per linear meter of the board.

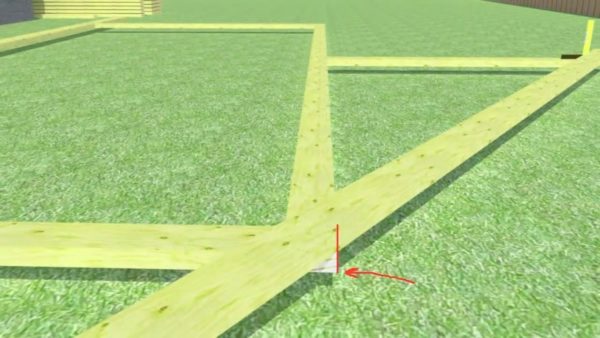

Assembly instructions for the truss system are as follows:

- We measure and mark the center on the beam at the top of the porch;

- We measure and mark the middle on the floor beam of the roof trusses;

- We join these two elements according to the marks made;

- We fasten the first lining along the edge of the pediment, moving it beyond the edge of the beam by about 30-40 mm;

For convenience, you can fasten the lining by applying a square to the edge of the beam as a template

.

- Since the standard length of the lining is 6 meters, it will not be enough for the entire pediment, and therefore the board will have to be increased;

Building up the board, we provide it with the required strength by fixing a small piece of the board with self-tapping screws from the inside

.

- We nail the second lining from the opposite edge, so that when building up, the next board strengthens the previous board;

- Thus, we sheathe the entire pediment with clapboard;

- We apply a straight bar along the ends of the pediment and cut the sheathing along it;

- Raise the finished pediment to a vertical position;

At least three people are needed to lift the pediment. That is, two lift, and the third strengthens. In order not to hold a heavy structure for a long time, the pediment is first temporarily attached with props. After the stability of the structure is ensured, you can proceed to the final installation

.

- After the front gable is installed, we raise the intermediate truss trusses up;

- Further, the rear pediment, like the front one, is sheathed with clapboard and fastened on the opposite side;

- We calculate the distance between the front rear gable and calculate an equal distance for installing intermediate roof trusses (the distance should not exceed 0.9 m);

- In accordance with the calculations performed, we mount the vertical rafters and fasten them with horizontal lintels.

On this, the assembly of the truss system is completed and you can proceed to the device of the roofing pie.

Installation of a roofing pie

Laying the sheathing on the finished truss system is carried out with solid boards with a thickness of at least 25 mm. The step of laying boards in the crate should not exceed 0.5 meters.

Boards laid across the rafters perform two functions, namely:

- serve as the basis for the flooring of the roofing material;

- strengthen the rafters increasing the rigidity of the system.

After the crate is ready, we process the rafters and boards with antiseptic and fire-fighting impregnations. Thus, you can significantly extend the life of the mansard roof. After laying the roofing material, such processing will not be possible.

Moisture-resistant plywood or oriented strand boards are stuffed over the boards of the crate.The slabs are laid in two layers with the displacement of the first layer relative to the second. Next, the installation of the roofing that you decide to use is carried out.

For the arrangement of wooden broken roofs, I recommend using soft tiles. This material is distinguished by an acceptable price and ease of installation, unlike metal tiles. In addition, such roofing material weighs little. Therefore, significant mechanical loads will not be applied to the finished roof.

Conclusion

Now you know how to build a sloping roof on a country house and other low-rise buildings. Are there any questions that need clarification? Ask them in the comments - I guarantee a timely answer. By the way, watch the video in this article - I'm sure you will be interested.

Did the article help you?