Almost any construction project, no matter what features it possesses, needs a well-organized roof. Perhaps the fastest and easiest solution here is a shed roof made of corrugated board. Typically, when building a residential building, roofing systems of this type are used in areas where strong winds are a constant phenomenon. As for other areas, in them single-slope systems are used mainly for sheltering garages and outbuildings.

Almost any construction project, no matter what features it possesses, needs a well-organized roof. Perhaps the fastest and easiest solution here is a shed roof made of corrugated board. Typically, when building a residential building, roofing systems of this type are used in areas where strong winds are a constant phenomenon. As for other areas, in them single-slope systems are used mainly for sheltering garages and outbuildings.

Nevertheless, when choosing this type of roofing system as a shelter during the construction of a residential private house, it can be stated with confidence that the house will be sufficiently protected and reliable and will have the technical characteristics that can be presented for the construction of this type.

Benefits of a pitched roof

- A roof with a simple shed design is considered the most cost-effective option when it comes to heating. Such a design is spared from the free space located between the arches of the classic gable roof.

- For the installation of such a roof, significantly less building materials will be required.

- The shed roof project will cost the developer almost nothing.

- The angle of inclination of such a roofing system is 25 degrees, thanks to which the roof will be able to successfully withstand strong winds that have a detrimental effect on roofing systems with a large slope.

- Roof structures of a single-pitched type, if necessary, can be repaired quickly, conveniently and safely in comparison with double-pitched systems.

Features of pitched roofs

To strengthen single-pitched structures, special curbs made of stone (usually the one from which the house itself is built) are used. They are easy enough to build with your own hands.

Thanks to the use of the curb, the roof has only one open side - responsible for the removal of rain and melt water. At the same time, the remaining sides are protected by a stone border.

Advice! The upper part of such a border is protected from natural influences with galvanized sheet iron, because if this is neglected, then the moisture absorbed by the stone surface will then be transferred to the walls, and this will reduce the life of not only the roof itself, but also the bearing walls of the house.

Shed roof construction

The device of roofs of a single-pitched type is produced as follows:

- Construction work begins with determining the appropriate angle of inclination, as well as the material to be used when sheltering the roof. Most often in modern construction, different types of corrugated board are used for this purpose - a fairly easy-to-install and high-quality material in operation. When working with corrugated board, the angle of inclination of the roof is taken at least 20 percent. A smaller slope can lead to the fact that with significant snowfall in winter, the roof simply sags under significant weight.

- After selecting the optimal angle of inclination of the roof, the front wall of the house is raised to the height required to achieve the clarified slope of the roofing system. Usually, instructions on the amount of wall rise are contained in the project of a private house, which is based on the technical indicators of the selected roofing material, as well as the wishes of the developer.

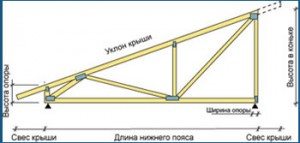

- Next, they proceed to the construction of the frame, on which the roofing material will subsequently be laid. It is most often made from well-dried and prepared for use (sanded) lumber. The number of frame cross members directly depends on the size of the roof and the roofing material used.

- Beams are laid on the upper part of the walls - the so-called seismic belt. If it is not provided, then a Mauerlat board is installed on the top row of masonry. Beams are laid in increments of 70-80 cm. The ends of the beams are taken out of the walls by about 50 cm.

- Vertical rafters are attached to the laid beams, which serve as supports for the high part of the roof structure. Supports are installed on each beam, thereby forming a right angle.

- Next, the rafters are attached, on which the crate will then be nailed. One edge of the rafters is placed on the edge of the beam in the lower part of the structure, the second - on the vertical rafters. The angle and height of the structure must be the same for all beam-rafter elements.

- Then the manufacture of the crate begins, which will allow the rafters to be connected into a single system and thereby provide the roof with the necessary rigidity. In addition, corrugated board will be attached directly to it. Reiki with a section of 50 by 50 mm are fastened across the rafters with nails. The distance from one rail to the next should be such that the laid sheet of corrugated board overlaps both rails with a margin of 15-20 cm on both sides.

- Cover the roof with corrugated board in rows, starting from the bottom. First, the first one is laid - it is also the bottom row, then the second, and so on until the end of the roof. Sheets of corrugated board are attached to the crate with special self-tapping screws with rubber washers.

Due to the slight angle of inclination, the installation of roofing material for this type of roofing system is considered to be low-labor.

However, the use of fall arrest equipment is still required to prevent falls from the roof.

Finishing roof deck installation work to the rafter system, they begin to install a wind board designed to protect the attic from blowing.

In order to better insulate the attic space, insulating materials are additionally used. This is used when the slope of the roof is large enough and the attic is used as a living/utility area.

Summarizing

So, we have analyzed how the construction of a shed type roofing system can be carried out using corrugated board, as well as, how to lay corrugated board on the roof yourself, as one of the most inexpensive and simple works in execution.

It is thanks to such positive qualities that many people tend to choose roofing systems of this type.

In one of the following articles, we will talk about how to make a gable roof from corrugated board: a video lesson of the installation process in addition to the article can give a more visual picture.

Did the article help you?