Slate has been and remains the most convenient and cost-effective roofing material for many decades, because it is very durable, copes well with snow pressure, and is fire resistant. Laying slate on the roof with your own hands is a fairly simple task, which makes the material even more profitable. In this article we will consider the features of slate and the subtleties in its installation.

Slate has been and remains the most convenient and cost-effective roofing material for many decades, because it is very durable, copes well with snow pressure, and is fire resistant. Laying slate on the roof with your own hands is a fairly simple task, which makes the material even more profitable. In this article we will consider the features of slate and the subtleties in its installation.

Preparatory work for laying slate

Slate sheets, which are sold in the form of packages, in which each sheet is lined with plastic wrap, should be stored in this form until they are lifted onto the roof for installation, as well as before installing the corrugated board on the roof with your own hands.

Slate packages are stored in a horizontal position, always in a place protected from direct exposure to weather factors.

For all its hardness, slate is a rather fragile material that cannot be thrown and cannot be walked on in shoes with metal heels.

Before covering the roof with slate, it is necessary to inspect the sheets for the presence of damage, scratches, cracks or other defects on them.

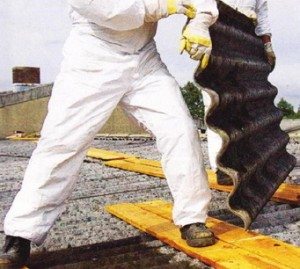

The layout of the material may involve cutting sheets, and this may require personal protective equipment, so how to lay both corrugated board and slate on the roof need to be careful.

Slate dust contains asbestos fibers, which are quite dangerous for the human body, so a fresh cut must be treated with water-dispersion acrylic paint without fail.

The minimum length of a cut slate sheet, at which it retains its strength properties, is 0.6 m, therefore, if necessary, excess length can be removed using an increased overlap.

The crate for slate is constructed according to the following rules:

- It should ensure the installation of most of the entire sheets.

- The step of the crate, as a rule, is 0.75 m, or 2 bars for each sheet, i.e. 2 times less than when installing plastic slate.

- For the crate, bars with a section of 60 by 60 mm are used.

- For the ridge, a beam with a section of 60 by 120 mm and boards 60 by 150 mm are used, which are laid close to the ridge.

- The valleys and cornices are covered with a continuous crate at a distance of 0.5 m, for which a board 60 by 250 mm is used.

Advice! Curved boards and bars should not be used, since slate is not a flexible material and it cannot hide defects in the crate.

Slate is fastened with special nails, for which holes are pre-drilled. Hammering nails into slate is prohibited, as it will crumble, but how to fix corrugated board on the roof with your own hands, is another question.

The length of the nails must be at least 120 mm, and also have a galvanized hat.

If you intend to cover the roof with slate yourself, you should take into account that it is best to use slate sheets with a roof slope of 10-25%. In addition, waterproofing must be laid under the slate without fail.

When installing slate on a roof with a slight slope, the joints of the slate sheets should be additionally sealed, which is optional for a roof with a large slope.

An expansion joint must be provided every 12 m of the coating. After laying the slate, it should be painted with a special paint, which will improve the appearance of the roof and significantly increase its service life.

Installation of a slate roof

Laying slate on the roof slope should be carried out so that the overlap falls on the leeward side.

For the convenience of the installation process, a twine is pulled along the eaves and the first rows of sheets are laid along it.

How to cover the roof with slate:

- Starting from the gable overhang, the first sheet is laid in the bottom row.

- Mount the next two sheets in the bottom row.

- Two sheets are laid in the next, top row and one in the bottom.

- In the horizontal direction, overlaps are made by the size of the wave.

- In the vertical direction, the overlaps are arranged in a length of at least 12-20 cm.

- Each sheet, in addition to the extreme ones, must be trimmed diagonally. Also, do not cut the corners of the eaves and ridge sheets.The dimensions of the cut corners are equal to the overlap. Cut the corners with a circular saw or a hacksaw, after which the sections are painted over. Breaking corners is prohibited, as the slate sheet may crack. After trimming, the corners are joined with a gap of 2-3 mm.

- Slate sheets are drilled under the nails before laying. Holes in diameter should be 2-3 mm larger than the diameter of the slate nails.

- A sheet of eight-wave slate is attached to the 2nd and 6th waves, seven-wave - to the 2nd and 5th, if you count from the overlap. Along the length of the sheet, the step between the nails is 10 cm.

Advice! The drilled holes must be additionally insulated with a rubber or plastic washer, and the nails are hammered in so that the cap rests slightly on the sheet, but so that the sheet does not dangle.

Features of laying flat slate

In addition to wave, there is also a flat slate. Flat slate is rarely used as a roof covering, it is mainly used for making fences, building temporary structures, for example, booths or gazebos, in rare cases it is used for cladding.

However, for those who still decide to take on the job on their own, some recommendations should be given on how to properly cover the roof with flat-type slate:

- The installation of flat slate is carried out along a continuous crate, while applying preliminary markings in the form of a grid on it. Such a grid consists of rectangles with a length of 23.5 cm and a width of 22.5 cm. It is possible to use flat slate sheets only on roofs whose slope is more than 18 degrees.

- The general laying technology is similar to the installation of wave slate.Rows of sheets are mounted from the bottom up, while horizontal installation is carried out so that the overlaps are on the leeward side.

- So that sheets of flat slate do not create a continuous joint throughout the roof, each of the odd rows starts from a whole sheet, each even row from its half.

The eaves are covered with steel plates, the valleys are made of galvanized iron. The pipes are sheathed with a steel apron.

The installation of the roof ends with the installation of the roof ridge. At the same time, a tape of roofing material is laid along the ridge beam.

From above, special ridge elements made of asbestos cement with grooves are strengthened. The gutters have different widths. The end, which has a wider gutter, is attached to the gable overhang.

How to calculate the number of slate sheets needed to cover the roof

In order to protect yourself from acquiring excess material, and also so that you do not have to re-go to the store with a lack of material, you need to correctly calculate the slate for the roof.

This procedure is performed as follows:

- First, the length of the house is measured, after which the resulting value is divided by the width of the sheet used and 10% is added to the overlap of the sheets. The resulting number will be equal to the number of sheets of slate required for laying one row of material.

- Next, measure the distance from the ridge to the roof overhang and divide the result by the length of the sheet. Then, adding to the resulting number 13%, which will go to the longitudinal overlap of the sheets, the number of required rows of slate is obtained.

- By multiplying the number of sheets in a row by the number of rows of slate, the total number of required slate sheets per roof covering is obtained.

Covering the roof with slate also involves a certain supply of slate sheets in case of marriage or damage to a certain amount of material.

Did the article help you?