The procedure for erecting a roof includes not only such work as the manufacture of the rafter structure, the direct laying of the roofing material and the installation of gutters, but also the filing of its eaves. This article will talk about how filing is done, what materials are used, and what a soffit is - filing a roof with the help of this article will become a much simpler procedure.

Properly completed construction of the house implies that its roof moves away from the wall at a distance of at least 50-70 centimeters, which ensures the protection of the facade walls from the penetration of rainwater.

At the same time, an overhang is formed in the roofing plane, covered from above with roofing material, and hemmed from below, for example, with clapboard.

In addition, hemming the roof in the case of mansard roof insulation also allows proper ventilation of the space under the roof or the gap between the roofing material and the insulation.

To do this, a draft of the air flow is created, coming from the lower mark of the overhang of the eaves into the space under the roof, gradually heating up and rising to the ridge, after which it exits through the ventilation holes.

This ensures continuous circulation of air in the space under the roof and effective weathering of moisture, allowing the structure of the roof to remain dry, which increases its service life.

Roof lining materials

In order to hem the roof, the following materials are usually used:

- Wooden lining, which has a low service life, requires periodic painting, absorbs moisture and blackens over time. In addition, this material does not have sufficiently effective ventilation.

- Vinyl siding, the profile of which is designed for facade walls, therefore, after hemming the roof, looks rather unattractive, and its appearance is only worsened by making holes for ventilation, which were not originally provided.

- Galvanized metal siding, which has a rather short service life, since it is not protected from corrosion and is located on the overhang of the roof eaves, where condensation often accumulates.On this material, brown rust spots appear quite quickly, especially noticeable if the color of the roof hemming is white or another fairly light one.

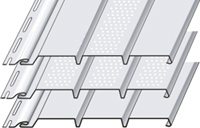

- Soffit made of vinyl, designed specifically for hemming cornices. This material has a ceiling structure, and various perforation methods can be used in its manufacture: solid soffit, perforated or with central perforation.

- Aluminum soffit made from thin colored aluminum sheets. The shape of the material is the same as that of vinyl soffits, but has a number of significant advantages, for example, the absence of a compression and expansion coefficient, which can significantly improve the appearance of the roof. When choosing how to hem the roof, this material is also favored by its ability to maintain color saturation for many years under the influence of direct sunlight.

What are soffits

When choosing how to make a roof hemming, a fairly common and reliable material is soffits made in the form of profiled polyvinyl chloride (PVC) or aluminum panels, the length of which most often ranges from 3 to 3.6 m, as well as two or three profiled strips of sizes 10 -12 centimeters each.

Useful: the specific size of the panel depends on the manufacturer, Canadian and American manufacturers quite often make a triple profile, the width of which is 30 centimeters, and the length is 3.6 linear meters, which is considered the most optimal size for hemming the roof with soffit, since it allows you to cut panels along the length of the projection roofs from the wall, but are joined together by the side parts, which makes it possible to combine their perforations.

Soffits of Russian manufacturers may differ in size, but have the same classification and installation principle.

Before you hem the roof, you should choose one of the three types of perforation produced soffits:

- Solid, most often used when filing the ceilings of gazebos, verandas, porches, etc.;

- Fully perforated, which is recommended for roofs covered with non-profiled materials such as seam or shingles;

- A soffit with a perforation in the center, which provides sufficiently effective ventilation of the space under the roof, while on the overhang of the cornice a composition is formed with alternating one perforation strip and two continuous strips.

Roof lining procedure

After the installation of the rafters is completed, in the process of making the crate for roofing, you should saw off the ends of the rafters along one line parallel to the plane of the wall of the house.

For sheathing the frame of cornice overhangs, either boards or profiles intended for drywall are used. The end parts of the vertically sawn rafters are sewn up similarly to the box itself.

Before hemming the roof overhangs, it is necessary to insulate the walls of the building from the outside, this is especially true for boxes sewn not directly along the rafters, but horizontally, which are the most common.

If you carry out the insulation of such a structure as a standard hip roof, after the manufacture of the box, then the upper part of the wall will either not be insulated, or its insulation will be possible only by detaching the first board from the wall, under which the insulation will be placed.

Insulation in this case will not turn out to be effective enough and will lead to heat loss, and performing insulation before installing the box will allow you to bring the sheathing to the previously insulated wall.

The procedure for filing the roof with soffits

The installation procedure itself is quite simple, but keep in mind that they must fit into the overall appearance of the house, so you should carefully study the instructions on how to properly hem the roof.

The design of the box itself can be individual depending on the specific roof structure, but there are two most common options that include common elements of filing:

- Hemming directly along the rafters, when an angle is selected for filing that matches the angle of the slope. This method is mainly intended for roofs with a small angle of inclination, while the installation of soffits is carried out directly on the rafters parallel to the plane of the wall. At the same time, if the lower plane of the rafters is not even, it should be leveled to ensure high-quality hemming.To do this, you can screw on the sides of the rafters trimming boards with screws, the thickness of which is at least 4 cm, and the length is at least 10 cm. First, the first and last boards are screwed, between which the threads are pulled and the rest of the boards are fastened. At the point of convergence of the slopes, the boards are fastened on both sides of the corner rafters.

- The most common option is when a horizontal box is made from the edge of the rafters to the wall, and the frame for filing the cornices with spotlights is also made of boards. One edge is fastened to the bottom of the rafters, the other to an additional board, which is lowered and fixed at the junction of the rafters with the wall. At the corners of the convergence of the slopes, the board is laid flat, since in this place there will be a joint where the two ends of the boards are fastened. This joint must run from the angle of convergence of the slopes to the angle of convergence of the walls, as a result of which a rigid structure independent of the wall is formed.

Important: special attention should be paid to the reliability of fastening, it can be done with screws, but it is better to use corners and metal plates.

After building the frame do-it-yourself hipped roof sheathing with soffits is made. Since rain, snow, wind, cold, etc. can penetrate this section of the roof, the fastening of the sheathing should also be carried out as reliably as possible.

The boards are joined along the length in a checkerboard pattern, two joints should not be allowed to be next to each other, except for the corners where sawing is performed at 45º.

The edged board and all the boards used for the equipment are treated on both sides with a special antiseptic protective agent.

Did the article help you?