When performing work such as covering or repairing a roof on your own, a special roof ladder is simply necessary equipment, which allows you not only to climb to the desired height, but also to maintain balance and stability when performing roofing work on rather steep slopes. Such a ladder can be purchased at specialized hardware stores, and in this article we will talk about how to make a roof ladder with your own hands.

When performing work such as covering or repairing a roof on your own, a special roof ladder is simply necessary equipment, which allows you not only to climb to the desired height, but also to maintain balance and stability when performing roofing work on rather steep slopes. Such a ladder can be purchased at specialized hardware stores, and in this article we will talk about how to make a roof ladder with your own hands.

During the operation of the roof, exits have to be periodically made exits to the roof, so the ladder for working on the roof is an almost indispensable item when living in a country house.

It not only provides safety when reaching such objects on the roof as ventilation outlets, chimneys, antennas, etc., but also protects the roofing directly from damage, since any movement on it that does not require special bridges and stairs for roofs , leave certain traces on the roofing.

For example, polymer coating do-it-yourself hipped roof deformed and damaged under human weight, bituminous tiles lose their waterproofing properties as a result of shedding of stone chips, etc.

In addition, one should not forget about the rather high risk of falling from slippery sloped roofing, which can be a serious danger to life and health.

Roof stairs classification

Roof stairs can be divided into several types:

- Attic;

- Wall-mounted;

- Installed directly on the roof slope.

For the manufacture of roof stairs of such a design as hip roof, materials such as steel pipes, aluminum profiles, wood, as well as various combinations of these materials are used.

Roof ladders made from galvanized pipes are usually powder coated in black, white or brown, other colors can also be ordered individually. The design of such ladders allows them to be assembled from separate modules without the use of a welding machine.

When talking about how to make a ladder for a roof, it should be noted that certain types of brackets are designed for attaching various types of ladders to a roof or wall.

When installing wall stairs, it should be borne in mind that the distance from the top step to the edge of the cornice should not exceed 100 millimeters, and the distance between the ladder itself and the wall should not be less than 200 mm. At the point of transition of the wall ladder to the roof ladder, the installation of handrails is mandatory.

The roof ladder is attached to the frame of such a structure as gable standard roof, with the help of brackets passing through the roofing. The connection point is sealed with special rubber gaskets. To achieve the required length of the ladder, its modules or sections are interconnected and the last module is attached to the ridge beam.

Not only waterproofing the roof, but also the life and health of people performing various work on them will depend on how to make a ladder to the roof, therefore, it is recommended to invite specialists to install roof ladders, and when doing the installation yourself, all requirements and norms should be carefully observed .

Self-made roof ladder

Roof repair stairs, both wood and aluminum, can be purchased at any store that specializes in building materials and tools, any roofing specialist has such a comfortable and safe ladder.

It is worth talking in more detail about how to make a ladder for working on the roof on your own, and not to purchase it ready-made.The manufacturing process of a wooden staircase will be described, since it is a more affordable and common material than an aluminum profile.

For the manufacture of a roof ladder, the following materials will be required:

- Board with a section of 16x2.5 mm;

- Bars with a section of at least 40x40 mm;

- Self-tapping screws or nails per 100 mm;

- Trimming boards and beams, the thickness of which is 40-60 mm.

Important: the large width of the side boards is chosen to avoid damage to the roofing material by the stairs, especially slate or ondulin. If the roof is covered with a corrugated roof, the gap between the axes of the sidewalls should be a multiple of the gap between the crests of the waves. For example, with a gap between the ridges of 10 cm, the gap between the axes will be 50, 60 or 70 centimeters, which will allow you to lay the ladder evenly on the roof without damaging the wave.

Crossbars for steps are made of bars, since it is more convenient to stand on them than on ordinary thin boards for two reasons:

- The leg on such a ladder will be located at a greater distance from the roof;

- The area on which the foot is placed or even one can sit down in certain cases is much larger.

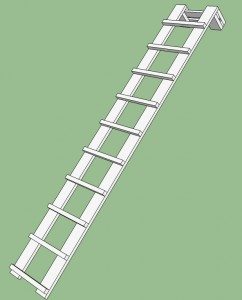

Useful: The ladder to the roof shown in the picture above is made with rather thin steps, which very quickly causes foot fatigue and other inconveniences.

You should also not place the steps too often, because steps too close together not only make the ladder heavier, but also interfere with its use.

To fasten the steps, nails of 100 mm are used, bent from the back side with the tip sunk into the wood.Screwing steps with screws is a less reliable option, especially in the case of a thin base.

Important: to avoid damage to the roof, carefully check the bending of all nails after nailing the steps.

Next, you should make a “hook” - a structure that allows you to hook the ladder to the roof ridge, which should be attached to the ladder as securely as possible, since the hook must support the weight of the ladder itself and the person on it.

This design can be made from several fairly thick boards, after which it is fastened with nails by 150-200 millimeters. The required length of the hook is from 30 centimeters, a larger value ensures its greater reliability.

Sometimes a board hangs from the back as a counterweight, for which the ladder clings. Adjusting the angle between the hook and the base of the stairs is done using special wedges or by filing the hook at the desired angle, which may not coincide with the angle of the structure.

Important: it should be borne in mind that with a small (20-30º) angle of the roof slope, the angle of the ridge will be about 60-70º, which requires either the manufacture of a large hook, or equipment on the reverse side of a sufficiently serious counterweight, such as the board that was mentioned higher.

If the length of the base of the stairs is insufficient, it is built up with the help of an additional board nailed over the overlap.

Important: you should not nail various hooks to the ladder, on which you can hang the tool, as clothes can catch on them, which will lead to loss of balance and a possible fall from the roof. For these purposes, it is better to use a special construction belt.

The movement of the ladder is carried out by two people, and one person must sit on the ridge, and the other, being on the ground or on the scaffolding, lifts the ladder, and together they push it in the right direction.

Independent production of stairs to the slope and on the walls

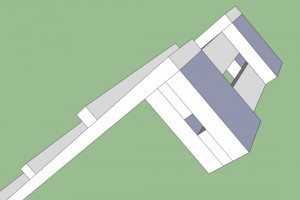

Pre-assembly of the stairs to the slope is made on the ground. First, the brackets for fastening the ridge are attached to the stairs, after which the roof supports are mounted on the places of the crossbars, the step of which is 2 meters.

The required length of the ladder is measured along the slope of the roof, sawing off the possible excess, after which the assembled ladder rises to the roof and is attached to the top board, which is part of the crate.

Also on the ground, stairs should be assembled on the walls.

The handrail and wall supports are being installed, the pitch of which is about two meters, and brackets for cornices are mounted to the upper wall supports, after which the ladder rises to the right place and it is fixed to the stairs located on the roof using two brackets, and the brackets for cornices are attached to wall supports.

In this case, it should be ensured that the lower rung of the ladder for the wall is located at a height of about 1 meter above the ground, and the upper one - at a height of about 10 cm from the level of the eaves.

Next, the pre-assembled brackets are fastened to the lower and upper edges of the lathing, while it is mandatory to install a sealant between the bracket and the roofing sheet, after which the transitional bridge is fastened using the bracket.

Did the article help you?