Many developers, having chosen this material, do not know how to cover the roof with waterproofing. It is for them that this article is intended.

Many developers, having chosen this material, do not know how to cover the roof with waterproofing. It is for them that this article is intended.

Material Advantages

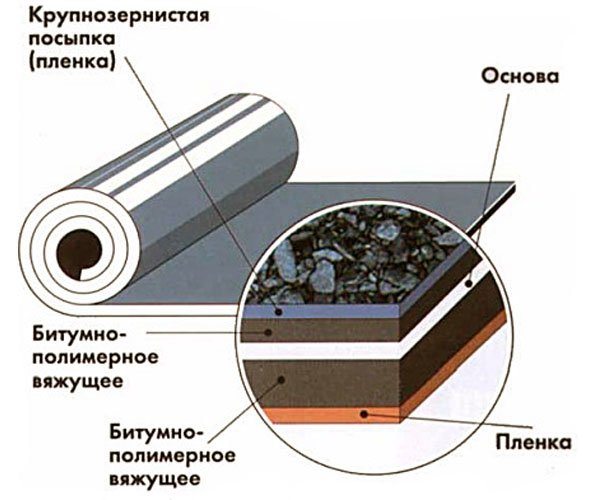

Hydroisol is a roll material based on fiberglass or fiberglass, coated with a polymer-bitumen composition on both sides. There are varieties of products with a base made of paper or cardboard.

On the wrong side of the rolls, a special thin film is additionally applied, which burns out and melts when laying the material.

The front side is covered with coarse-grained mineral or granite chips.The material is ideal for covering flat roofs, as well as roofs with a low slope. Often it is used as a waterproofing coating for foundations.

If you intend to cover the roof with waterproofing, you will need a roofing type of material, which includes bitumen-coated cardboard. For foundations, a paper-based coating is used.

In principle, the difference between them is small, except that the roof type is slightly more expensive due to the thicker base, and a little heavier.

Fiberglass used in the production of coatings makes the material not only plastic, it gives it strength, resistance to moisture, fire and mechanical damage. Elasticity and ease of installation can also be added to a number of advantages.

How to choose the right coverage

Before buying a hydroisol, decide for what purpose you are purchasing it. For lining under roofing or for waterproofing, the so-called bottom layer is produced.

Note! For the final covering of the roof, it is better to purchase the top type, designed for roofing without subsequent laying of other materials on it. You can identify this type by the letters on the package. The letters HPP and CCI mean that in the first version there is a canvas, and in the second - fiberglass. The letter P indicates the presence of a polymer protective film.

For the top types of coating, there is the letter K on the package (HKP and TKP), it makes it clear that coarse-grained mineral dressing is used in the material. It not only gives strength, but also prevents the bitumen from melting under the influence of sunlight, as it reflects them.

It is desirable to store the purchased hydroisol in a dry, ventilated room, at room temperature, in rolls.

Similar products

Materials identical to the waterproofing are produced, which, nevertheless, differ slightly from the latter in their characteristics, and this garage roof covering will be reliable.

Some may be interested in the question: how to cover the roof with bicrost, and how it differs from other materials. Fiberglass coated with a bituminous binder is resistant to moisture, fire and other influences.

It is laid on a surface, carefully leveled and cleaned of debris and dust, covered with bitumen. First, the material is rolled and cut.

Then, one by one, the rolls are unrolled in the same sequence, and with the help of a propane burner, the lower part of the roll is melted, slowly rolling it towards itself.

When one roll is fused to the surface, the same is done with the second, laying it parallel to the previous one with an overlap of about 10 cm. Thus, the bottom layer of bicrost, when melted, firmly adheres to the surface.

Now let's figure out how to cover the roof with linochrome, another bituminous roll material. The principle of laying differs little from the previous one. Linocrom is a material similar to hydroisol.

Fiberglass or canvas, covered from the inside with viscous bitumen and a special film, has a similar bitumen layer on the outside, sprinkled with sand or shale. It is the fusible film of the lower part that gives an adhesive effect when melted.

Just like the previous ones roofing materials, it is advisable to use it for covering flat roofs, or roofs with a slight slope.It is recommended to use one-layer laying for the repair of old coatings, and two-layer technology for the installation of new ones.

When purchasing linocrom, pay attention to the type of coating that will be indicated on the package. Each category of material is marked with letters that indicate its specific purpose. HPP, HTP, TKP, Chamber of Commerce and Industry, EKP, EPP are letters that make it clear on what basis the material is made and what it is best suited for. X - canvas, T - fabric, E - polyester.

Anyone who is interested in how to cover the roof with rubemast, in the same way, should stock up on a propane torch, with which you will melt a special film on the wrong side of the material. Its basis is cardboard or fiberglass.

Just like in previous materials, the final roof trim made of sand (fine-grained coating) or slate (coarse-grained coating). In this case, the letter K on the package will mean a coarse-grained layer, the letter M - fine-grained, and P - polymer film protection.

Gradually it becomes clear that the question - how to cover the roof with technonicol, is similar in its process to all the previous ones. It, like all the previous ones, refers to the type of deposited materials.

In other words, the film melted from the burner on the wrong side adheres firmly and permanently to the base.

She, as in the previous cases, is bituminous mastic, which can be easily purchased at hardware stores. In extreme cases, it will not be difficult to make the composition yourself - buy bitumen in bays, melt it, then mix it with any solvent (kerosene, gasoline) in the ratio: 3 parts bitumen + 1 part solvent.

The pre-cleaned and leveled surface is poured with this mixture, and wait until completely solidified. Then the material is rolled out from the roll, cut, and rolled up again.

The burner is turned on, the roll is laid from the beginning, the lower film is melted, carefully moving the burner horizontally from side to side, and the melted part of the roll is rolled up in the direction “towards you”.

Similarly, the roof is covered with bikrost, which almost exactly repeats the technology of its manufacture with all previous roofing materials.

The main thing is to choose when buying exactly what is needed for your particular case. Because, for the roof, you need material on a thicker and more durable base, and for waterproofing the foundation, you can choose protection a little thinner and cheaper.

After reading the article, you came to the conclusion that the described material differs only in the name and, accordingly, the manufacturer.

Its manufacturing technology and principle are similar. Melt film on the inside, a slightly different base, designed for different purposes, a protective film on the outside and an exclusive coating.

Flexible, durable and reliable material, easily mounted on a smooth surface, will provide your home with reliable protection for a long time.

The principle of laying the waterproofing, as well as all the previously listed materials, has one thing in common - the molten bottom is firmly and permanently glued to the bituminous base, pre-filled.

The main thing is to ensure that the surface is perfectly flat, the material is of high quality, and the work is conscientious. Then your do-it-yourself roof will last not for years, but for decades.

Did the article help you?