Motorists know firsthand how the roof of the garage flows. This problem can be quite intrusive, especially in the phase of the change of seasons. Is there really no way to perform a high-quality and long-term coating? In this article, we will take a closer look at the garage roof covering, namely the necessary building materials and the recommended operations.

Motorists know firsthand how the roof of the garage flows. This problem can be quite intrusive, especially in the phase of the change of seasons. Is there really no way to perform a high-quality and long-term coating? In this article, we will take a closer look at the garage roof covering, namely the necessary building materials and the recommended operations.

So, it doesn't matter if you lay a new roof or re-lay the old one, the work is the same. Spot repair of the roof is not a thankful task, it will not be enough for a long time. If the water has gone, then it will find the passage anyway.

The roof of the garage, like any other building, will be divided into flat and sloping. If the angle of inclination of the roof is less than 15 degrees, we will consider it flat, otherwise - sloping. Accordingly, both materials and work will be fundamentally different.

Flat roof

Such roofs are most often found in garage cooperatives. It is enough just to cover the roof of the garage with roofing material. Usually, two reinforced concrete slabs, covered (or not yet covered) with a water-repellent layer, lie on the brick walls.

Accordingly, such a roof has three weak points: the joint between the plates and the side joints of the plates with walls or other plates.

For the most part, such roofs are covered with roofing material.

Let's look at how to cover the roof of the garage with roofing material.

Instruction:

- Very thorough cleaning of the surface floors before waterproofing the roof of the garage. We sweep away dust, remove all kinds of garbage. If the roof is wet, it must be thoroughly dried. If there is little sun, you can dry it with a burner, but not with a gas one, but with a blowtorch.

- If the roof of the garage was previously covered, we examine it for defects, such as blisters, delaminations, holes. We cut the swellings with an “envelope”, open the four corners and remove the water. Dangling places are removed, cleaned.

- We heat bitumen.

Tip: bitumen consumption depends on the unevenness of the roof. If the garage is 3x10, i.e. the roof is about 30 sq m, so two buckets of bitumen is enough.

- How to fill the roof of the garage. When the bitumen has melted, we prepare the primer (primer for roofing material). Slowly pour melted bitumen into gasoline (76th), stirring all the time. If gasoline is poured into bitumen, it can ignite

- We are preparing two compositions in the ratio of gasoline / bitumen: 30x70 (liquid) and 70x30 (mastic). The liquid composition is a primer. It fills cracks, cracks, delaminations. We level the entire surface of the roof with mastic.

Tip: the bitumen layer should not be more than 5 mm, otherwise it will “break” in winter.

- If we make repairs, then in places where the coating is destroyed, we apply additional patches from roofing material.We glue them with a torch. We heat the roofing material to such a temperature when it does not overheat, does not bubble, but becomes very shiny. The roof also needs to be warmed up.

Tip: carefully press the hot material over the entire area. The durability of the coating depends on this.

- Now we cover the roof with lining layers of roofing material. We stack them from the bottom up, i.e. from the lowest edge to the highest. We overlap about 15 cm. We warm up and trample very carefully, if there are no glued places, we trample them or nail them with soft material. The service life depends on the quality of the fit. Condensation will form in the air vents, the water from which will quickly destroy the roofing material.

Now you need to fill the roof of the garage with bituminous mastic, or rather lubricate it with a thin layer. We put the second lining layer perpendicular to the previous one.

We wrap the edges and fix with slate nails on the reverse side. Lubricate again with mastic.

Tip: the edges of the rolls and joints can be additionally smeared with a thick primer.

- Now put on the top layer. It is distinguished by the presence of a coarse powder that protects the roofing material from external weather influences. We check the fit, the quality of the overlap joints, fix the edges. The roof is ready.

If everything is done well, then repaired garage roof will last 10-15 years. There are more expensive and plastic analogues of roofing material, such as rubemast and euroroofing material. These materials are much more wear-resistant, the roof of them will last about 30 years. We lay the material carefully, wrinkles on the surface are not allowed.

Previously, the garage roof was filled with resin, but such a coating is extremely short-lived.

sloping roof

The roof can be single or double. It does not matter, the main thing is that the slope is at least 15 degrees.

Usually the roof is made with a crate, followed by upholstering it with wooden boards. So how to cover the wooden roof of the garage?

If the garage is located next to the house, then for aesthetic purposes it is recommended to make its roof by analogy with the roof of a residential building. It will turn out very beautiful and durable. Such work can only be done by qualified builders with experience and skills, and the cost will be at the proper level.

If you want a more modest result, then consider the most common options for covering a sloping roof:

- Cink Steel.

- Decking.

- Slate.

Galvanized garage roof coating is widely used due to its ease of operation and low material cost.

It is enough to install such a roof on the rafters with a step of 90-120 cm. You can take a beam for the crate 50x50, 30x70, 30x100 mm, it depends on the load on the roof. Please note that the smaller the angle of the roof, the greater the pressure of snow on the floors.

It is quite possible to lay galvanized sheets yourself, without having special skills. A little lower, using the example of corrugated board, we will consider the installation process in more detail. We simply bend the joints of the sheets to one of the sides, we also perform a skate.

The professional flooring represents the galvanized steel only stamped with a certain profile. Sheets can be additionally covered with a polymeric material, which not only creates an additional layer of protection for the material, but also looks very nice from the outside.

Consider how to cover correctly - cover the roof of a garage with profiled steel sheets:

- Sheets can be cut both with metal scissors and with a hacksaw, placing a wooden beam for convenience. When calculating the number of sheets, take into account the overlapping of one cell and the overhang from the edge of the roof by 20 centimeters.

- We make the crate by analogy with the galvanized roof discussed above. By the way, if you are concerned about the question of how to raise the roof of the garage, then you can do this using the same crate.

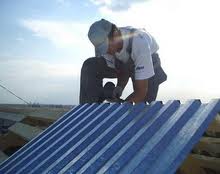

- We start laying the roof from the bottom edge. We lay the sheets overlapping along the perimeter of the roof, attracting them with special self-tapping screws.

They are distinguished by the presence of a neoprene gasket under the washer, which will ensure the tightness of the connection. They usually take a screw with a diameter of 4.8 mm and a length depending on the height of the profile cell, so that the connection is reliable, but not less than 35 mm.

The end of such self-tapping screws is made in the form of a drill, so there is no need to pre-drill a hole in the sheet; using a screwdriver, installation is quick and convenient.

Attention! Screw the screws strictly perpendicular, without kinks, otherwise the connection will not be tight.

When laying the first row of sheets, the main task is to align the edge of the coating with the bottom edge. On the extreme row of flooring, we drive self-tapping screws into each cell of the profile, and above - through one.

Tip: although for corrugated board fixed with a special self-tapping screw with a sealed gasket, there is no mandatory requirement to be attached only to the upper part of the profile, we still recommend sticking to it.

- The skate can be purchased separately, or it can be bent from a sheet if the aesthetic part does not bother you much. You can also separately purchase side decorative elements for corrugated sheets.

That's all, the roof is ready.

Although corrugated boarding has replaced the good old slate, roofs are still made from it quite often. Whether the habit of generations affects, or something else, but in fact the strength of slate is inferior to corrugated board, and the service life is less, but the fact remains.

Such a roof spreads by analogy with a profiled sheet, only the fastener is not a self-tapping screw, but a slate nail with a rubber seal to seal the hole. And here the rule is ironclad: a mounting hole is allowed only in the upper part of the slate wave.

We invite you to watch a short video about roofing.

How to cover the roof of the garage video.

Did the article help you?