Do-it-yourself garage roof is a good thing. But, before you start work, you need to decide on its type and type of roofing materials. How, what is done and what materials are used - you will find the answers in our article.

Do-it-yourself garage roof is a good thing. But, before you start work, you need to decide on its type and type of roofing materials. How, what is done and what materials are used - you will find the answers in our article.

If there is a building, but the roof of the garage is leaking or the roofing material is not suitable, you can simply replace it.

Well, if the construction is only in the project, it will not be superfluous to find out what types of roofs exist. This will facilitate the choice and help to correctly calculate your strength.

Roof types

There are two types of roofs: flat and pitched.

Flat roofs are not really flat, they just have a slope angle of no more than 2.5 degrees. Attic space in such buildings is not provided.

As a roofing material, soft types of roofing are used: roofing material, glass bit, bikrost. This option is perfect for garage cooperatives. Garages are located right next to each other and it is impossible to make a roof in a different way.

Pitched roofs are made at a stronger slope (15-60 degrees) and provide for an attic space.

They have a more complex structure of wooden or metal rafters.

There are several types of pitched roofs:

- Do-it-yourself shed roofs - are simple to manufacture, but durable construction. The front of the building is higher than the back, due to this, a slope, a slope is obtained. Great option for garages.

- Gable roofs, as the name implies, have two slopes. In appearance, the roof resembles a tent, the design is a little more complicated than the previous version, but it can also be done independently. Garages with such a roof are made in private houses, if the building stands separately and there is a desire to equip a room upstairs for relaxing or storing various little things.

- Hipped or hip roofs have a complex structure. It is rarely used for garages, only to match the design of the entire site.

- Direct mansard roofs not as difficult to build as tented ones, but you can’t call them simple either. Its advantage is a large space. For garages, it is used in cases where you are going to live above it, otherwise there is simply no point.

Now let's look at what kind of garage roof material you can use.

Roofing materials

Roll materials based on bitumen or tar, glass base with plasticizers. These self-guided materials are widely used to cover pitched and flat roofs.

The installation process does not take much time, it is not difficult to cope with this matter, but you need to know some features. Such materials are not very expensive, but their service life is not long (8-10 years).

The metal tile is made of galvanized iron, which is covered with a protective layer. The material has a number of advantages: strength, easy installation, light weight, service life of more than 50 years.

Mounted on a wooden crate. To carry out work on metal roof installation no special equipment or knowledge required. It is used for pitched roofs of detached garages.

The professional flooring is a facing sheet from galvanized steel. The material is available in different colors, which helps to make the roof more elegant. It has the following number of advantages: resistance to atmospheric precipitation, strength, not subject to corrosion, has a light weight and will last for many years.

Ondulin - cardboard impregnated with bitumen. It is intended for roofing, but is not in great demand due to a number of shortcomings: it burns quickly, the paint will peel off within three years, during installation there is a large consumption of fixing materials, the service life is not more than 10 years.

Choose for yourself how to close the roof of the garage. These are the main, most commonly used roofing materials.

It's time to tell you how to build a garage roof. The construction of two types will be described below: flat and shed structures, since these types are the most common.

Flat roof

For a heated and unheated room, the roof is built in different ways.

If it is decided that the garage will not be heated, the roof will be built like this.Beams are laid on the walls under a slope (3 cm). Then they put a board shield on them.

Roofing material is spread on top. Wooden or metal slats are used as fasteners. They are stuffed along the entire slope at a distance of 60-70cm from each other. All the roof is ready.

If it is decided that the garage will be heated, the work is carried out in the following order.

- Beams or reinforced concrete floor slabs are laid on the walls.

- From above, lay a layer of roofing material in an overlap, overlapping at least 15cm.

- A layer of insulation is poured. For these purposes, you can use slag or expanded clay. With the help of it, the slope of the roof of garages is formed.

- A cement screed is being made. Its thickness must be at least 2 cm. Now the roof should stand for several days until the solution gains strength (5-10 days).

- Bituminous mortar must be applied to the screed or melted resin can be used.

- Roofing material, soft roofing is laid on this carpet. For these purposes, materials based on bitumen or glass are usually taken. Roll in several layers. The overlap in a row can reach 1/3 of the roll width.

- At the end, all joints and junctions are coated with waterproofing mastic or the same resin.

Garage roof ready. From the inside of the building, it can be additionally insulated. This is done with the help of mineral wool or polystyrene.

On top of them it will be necessary to lay a vapor barrier so that the insulation does not absorb moisture. After that, the ceiling is covered with clapboard or plywood sheets.

shed roof

How to make a garage roof It is not difficult. First you need to decide on the angle of inclination. Usually it is no more than 25 degrees.

To reach it, the front wall of the garage is made higher than the back, to a height that will provide the desired slope.Now you can start building the roof frame. To do this, you need bars, boards and logs.

First stage. The beams are laid on a seismic belt, which must be specially poured in the upper part of the walls. If it is not there, it will be necessary to install a murlat board in this part of the walls. Beams are placed at a distance of 70-80 cm from one another.

Second phase. Support beams of the high part of the roof, vertical rafters are attached to the laid beams. We install them on each beam. The result is a right angle (between the beams and the vertical rafters).

Third stage. We lay the rafters on which the crate will be attached. We put them in the same way on each beam. One end of the rafters is laid on the lower beam, and the other on the vertical supports of the upper part of the roof.

Advice! Remember to check the height and angle of the roof. These values must be the same everywhere.

Garage - roof The fifth stage includes nailing the crate. It is needed to stiffen the structure and roofing material is attached to it.

For this, slats measuring 50x50mm are used. They are nailed across the rafters. The distance between the laths of the lathing should be such that a sheet of roofing material can overlap two laths and leave a margin of 15-20 cm on each side.

Sixth stage. Roofing material is laid. Start from the bottom. The first sheet is attached from the edge, but not tightly. Then the next two are laid. Align everything along the edge and fix it completely. Then put the next row and so on to the top.

Advice! The roof of the garage roof is overlapped. For slate and profile materials, an overlap equal to one wave of material will suffice.

Seventh stage. Clogging of the wind pediment.To do this, you can use wooden boards or lay out brickwork. Do not forget about the ventilation of the room and the under-roof space.

Previously, slate was used as roofing materials for the roof. Now it is being replaced by more modern materials - corrugated board and metal tiles. And it's not just about looks and durability. Modern materials are lightweight and during installation they do not split like slate.

A roof made in this way does not guarantee warmth in the garage. She needs to be warmed up.

Roof insulation

A cold garage is not a very convenient place to repair a car, and it will not benefit the car itself. Therefore, it is recommended to immediately insulate it during the construction of the roof, as well as take care of ventilation. How to insulate the roof of the garage?

For this you will need the following materials:

- Insulation. It can be pressed mineral wool, polystyrene foam, polystyrene foam or other heat-insulating materials.

- Steam and waterproofing. Previously, roofing felt was used for these purposes, but it is not very suitable if the roof for the garage is made of profile metal. It was replaced by new materials: diffusion membranes and waterproofing films. Thermal insulation can be foil or look like a regular film. It is not necessary to buy both materials. You can take one and use it as a vapor and waterproofing.

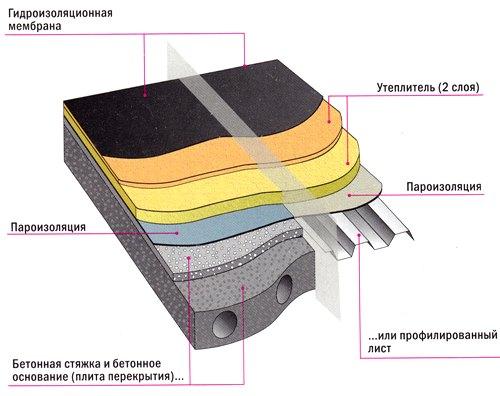

It is better to do this immediately during construction, the effect will be better. The device of the garage roof after insulation will look like this, let's start with the layers located on the inside of the room.

- decorative layer.We sew up the ceiling with plywood or clapboard.

- Vapor barrier. Stuffed on the rafters, over the insulation. The film or membrane must cover the entire surface of the roof hermetically. To achieve this, the joints are glued with a special tape, and the insulation itself overlaps.

- Thermal insulation (insulation). Usually, experts recommend making the distance between the beams equal to the width of the insulation.

- Waterproofing. The diffusion membrane is laid over the insulation. This material can pass moisture and steam only in one direction, up.

- Control grid. Performs three functions at once. A crate is attached to it, it holds the waterproofing and helps to ventilate the under-roof space (between the roofing material and the diffusion membrane, a distance equal to the height of the counter-lattice bar is obtained). The slats are attached to the rafters, along their entire length.

- Crate. Reiki are attached to the counter-lattice in a checkerboard pattern.

- Roofing material.

Now it’s clear how to properly make the roof of the garage so that it is warm. In principle, the work is not difficult and even beginners can do it. If something is not clear, you can consult a specialist or watch a video on the Internet.

We have described the most common garage roof designs. In general, it all depends on where the building is located and how it is located.

For example, if we talk about free-standing buildings, then this can be a gable roof of a garage made of profile metal. This is also not a very complicated design, but it is hardly suitable for a garage cooperative.

Did the article help you?