Do-it-yourself garage roof waterproofing is not only one of the construction stages. This layer is designed to protect the room from moisture and does not disturb the thermal insulation. Without it, your garage will be constantly damp, which is not good for a car.

Do-it-yourself garage roof waterproofing is not only one of the construction stages. This layer is designed to protect the room from moisture and does not disturb the thermal insulation. Without it, your garage will be constantly damp, which is not good for a car.

Garage roof insulation is an important stage of construction. Any specialist will tell you that it is not enough just to lay the insulation, you must also take care of its protection. For these purposes, special hydro- and vapor barrier materials are used.

Remember! Waterproofing is designed to withstand the adverse effects of moisture and precipitation. The roof is exactly the part of the structure that is the first to feel the influence of these factors.

So, what is roof waterproofing? This is a complex protection, which is designed to protect the inner and outer surface of the roof from the influence of precipitation and the appearance of condensate.

It should be borne in mind that it is not enough to lay high-quality roofing material, only high-quality and correctly laid metal roof layers give reliable results. Therefore, to begin with, we propose to consider the device of the roof.

Roof device

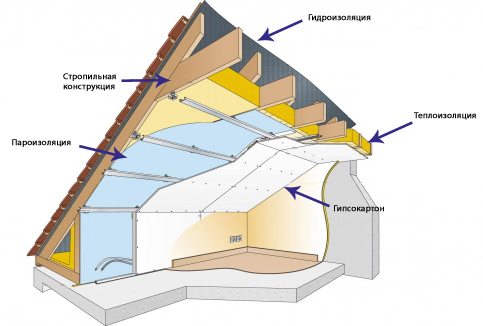

It is shown in cross section in the figure. Such a roofing "pie" is typical for pitched roofs. The device of flat roofs will be described below.

Let's list all the layers in order, starting with the top outer coating:

- Roofing material.

- Crate.

- Control grid.

- Waterproofing.

- Insulation.

- Vapor barrier.

- Internal lining.

It is worth noting that it is more convenient to carry out work on roof insulation and waterproofing during the construction process, and not after, when it gets cold and it will be necessary to urgently solve something.

Therefore, after installing the truss system, you should start warming. You can start work both from the outside and from the inside.

The sequence of insulation of pitched roofs

Insulation is laid between the rafters for these purposes, you can use the following materials:

- Stone wool - slabs made of mineral wool. They have a high heat-saving capacity, low water absorption, non-combustible, resistant to microorganisms and rodents, easy to install. You can also use rolled materials with special protection against moisture.

- Expanded polystyrene foam is a lightweight gas-filled material from the class of foam plastics. This material is more effective than mineral wool in terms of thermal insulation properties, it is non-combustible, and has a low weight. Service life up to 50 years.Most often used for flat roofs. It is possible to use this material in a flat roof on a profiled sheet.

- Polyurethane foam - belongs to the group of gas-filled plastics. Due to low thermal conductivity, low vapor permeability and high waterproofing characteristics, this material is widely used for insulation of roofs and attics.

- Glass wool is a type of mineral wool, made from glass waste. It has good thermal insulation characteristics. The main disadvantage is the increased fragility of the fibers, which, settling on the skin, cause itching.

On both sides, the insulation is closed, from below - with vapor barrier, from above - with waterproofing. We knowingly connected these two layers in one paragraph.

These materials are not very different from each other. Some advise using the same name for both layers.

The following materials are suitable for this:

- Roofing film is designed to protect the space under the roof from dirt, dust and moisture that may occur after rain. In attic-type roofs, the insulation is protected from the penetration of moisture from the outside. Thanks to microperforation ventilation of water vapors from internal rooms is provided. The film is intended for sloping roofs with a ventilated system.

- Roofing anti-condensation film is used in ventilated sloping roofs and protects the interior from dust, soot and moisture arising from atmospheric precipitation. In its manufacture, viscose is used, so that the condensate does not drain onto the insulation, but is absorbed. Recommended for profiled roofs.

- Superdiffusion membranes are used to protect under-roof spaces, attics and insulation from moisture, dust and wind. Due to the high vapor permeability, rapid weathering of water vapor from the interior is ensured. Used for all types of roofs.

- The vapor barrier film prevents the penetration of water vapor into the insulation, which reduces moisture condensation in the insulation and prolongs its service life. It is used on the internal surfaces of the under-roof space and attic spaces.

- Connecting tapes provide durable vapor tight joints. Used for fastening vapor and waterproofing, gluing them to wooden or other surfaces.

Advice! The vapor barrier is laid in overlap. Then all joints and fittings must be glued with a connecting tape.

On the inside, after laying the vapor barrier, cladding is done. For these purposes, you can use moisture-resistant drywall, plywood, plastic or lining. Here, who is on what much.

From the outside, a counter crate is stuffed over the insulation. For this, bars or slats are used. Their height must be at least 2 cm. this is done in order to ensure ventilation of the under-roof space.

The bars are stuffed on the rafter legs, parallel to them. Work should be done carefully so as not to damage the waterproofing. If this happens, use a connecting tape, seal the gap.

The next step will be the installation of the crate, on which the roofing material will be mounted in the future. You should be aware that when using a soft roof, the crate will be continuous.

Make it from OSB sheets. For pitched roofs covered with metal tiles or corrugated board, 50x50 slats are used. They are nailed to the counter-lattice in a checkerboard pattern.

Next, proceed to laying the selected roofing material. It can be profile sheets, tiles, etc. We propose to consider the allowable dimensions of the angle of the slopes for the most popular materials.

- Slate roof - slope angle 20-35 degrees;

- Soft roof (roofing material) - the slope angle is not more than 5 degrees;

- Decking - roof slope from 8 degrees;

- Seam roof: 18-30 degrees;

- A roof covered with metal tiles must have a slope of at least 14 degrees.

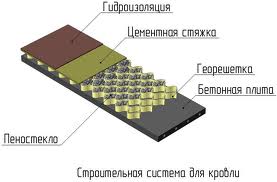

For flat roofs, the roofing "pie" device will look like this:

- Reinforced concrete slabs.

- Ruberoid.

- Insulation (slag or expanded clay).

- Cement strainer.

- Bituminous rubber mastic or primer.

- Soft roof (evroruberoid, stekloizol, bikrost).

- Waterproofing mastic, primer.

From the inside, flat roofs can also be insulated with heat-insulating materials, and then a vapor barrier can be laid. After that, the ceiling is closed with internal lining.

In principle, roof waterproofing in garages is not a difficult task. The main thing is to choose the right materials. If something is not clear or you have questions, we suggest watching the video of the garage roof with your own hands.

Did the article help you?