In fact, the choice in this matter is not great. It all depends on the material of the floors, as well as on the angle of the roof. In any case, if you do not have many years of building skills and a team, then the question of how to cover the garage roof is decided either in favor of roofing material and similar materials, or in favor of a profiled sheet with its options.

In fact, the choice in this matter is not great. It all depends on the material of the floors, as well as on the angle of the roof. In any case, if you do not have many years of building skills and a team, then the question of how to cover the garage roof is decided either in favor of roofing material and similar materials, or in favor of a profiled sheet with its options.

The choice of material largely depends on how the roof is constructed structurally. It can be a wooden crate, it can be reinforced concrete floors.

Usually they try to cover the roof with sheet metal or profiled sheet, because. it's fast and doesn't require much skill. However, this method is suitable for a roof with a slope angle of more than 15 degrees, otherwise the structure may simply not withstand the pressure of snow in the winter.

Collective garage buildings are made of brick or concrete, and reinforced concrete slabs are mainly used as floors. It is better to cover such a roof with roofing material and similar materials. Let's consider both options in more detail.

Roof made of concrete slabs

If the roof of the garage is leaking or it has never been covered with waterproofing material, then the most affordable and cheapest way to cover is roofing material.

The preparatory stage is very important in laying the material. Its implementation depends on whether the roof is new or it already has bitumen.

So preparation:

- If the concrete slab is new, then before pouring it is necessary to screed the roof of the garage with concrete. This is done so that moisture from condensate and other liquids do not collect in the bumps later. The service life of the coating depends on the quality of the screed, keep this in mind.

- In the case when the plate already has an old coating, it is necessary to dismantle the pieces that have fallen off, the bubbles must be cut in the shape of an envelope, the corners should be moved apart and moisture completely removed from the voids.

- If there are cracks in the roof, they need to be cleared and deployed. Repairing a garage roof leak requires a close inspection of every inch of coverage.

Our roof is ready for wetting with a primer layer.

We begin the first stage of work:

- We need roofing material at the rate of two layers of lining and one final. It is distinguished by a layer of backfill, which prevents the destruction of the material from external influences.

Tip: when calculating the area, keep in mind that the roofing material will need to be bent over the edges of the roof, and it will spread with an overlap of 15 cm.

- We put bitumen on the fire. The standard garage roof area for two slabs is approximately 30 square meters.For such a roof, two buckets of bitumen are enough.

- While the bitumen is melting, we very carefully sweep the surface from debris and dust.

- The first layer is preparing a primer. It is done like this: slowly pour molten bitumen into gasoline (76th), mixing thoroughly. If you pour gasoline into bitumen, that is, there is a risk of ignition, you do not need to do this. The ratio of gasoline / bitumen for the primer is approximately 70/30. Pretty liquid substance, what we need.

- We pour this primer over the entire surface of the roof and let it soak and dry. Especially carefully pour into cracks, joints, under the old coating.

- We prepare the second layer - mastic. We do the same, only we maintain the ratio of gasoline / bitumen approximately 30/70. It will turn out a thick substance, which we apply in an even layer of no more than 5 mm, leveling out all the irregularities.

Tip: if the mastic layer is more than 5 mm, the material may break in winter from frost.

Now you can lay the roofing material. Roofing the garage. To do this, we need a burner, but not gas, but gasoline or kerosene.

Pour gasoline into it, pump up the necessary pressure and proceed:

- We start from the lowest section and lay the first layer. Do not forget to leave a supply of material to wrap the roofing material under the roof.

We heat the roofing material evenly and, to a lesser extent, bitumen. Do not overheat, usually the material is ready for gluing when it starts to shine brightly.

We pay special attention to the density of gluing, there should be no air gaps and folds. We trample down every centimeter qualitatively.

- We also cover the surface of the entire roof, laying the material with an overlap of 15 cm. You can additionally coat the joints with bitumen, although this is not necessary. We coat the surface with a primer.

- Now we put the second layer of roofing material.We do this perpendicular to the first layer, again carefully trampling the material. Again we coat the surface with soil.

- Now we lay the third, final layer of the coating. We take roofing material for this with a layer of powder for weather protection. We lay it perpendicular to the previous one. We also warm up the edges, wrap and press. Fix with something like slate nails.

This design will last at least 15 years without garage roof repair needs. There are now substitutes for roofing material on the market, such as rubemast, bikrost, in general, what is popularly called euroroofing material.

If you are wondering how to cover the garage roof with bikrost or rubemast, then the technology is the same as in the case of using roofing material. These materials are based on fiberglass, which means they are stronger and more durable than roofing material. The roof of them will last at least 20 years.

Timber roof

The frame of such a roof consists of wooden rafters and battens. A metal profile is sometimes used as rafters, but this is not economically feasible, since it greatly complicates the installation process.

This garage roof it can be shed (figure above), this is the simplest option, and gable, which is more practical in terms of organizing an additional attic space under the roof where you can store garden tools, building materials, etc.

Let's look at how to cover the garage roof with profile material:

- For the crate, a 50x50 beam, or more, depending on the angle of the roof and the material used, or a board 150x25 mm, is suitable. For rafters, we take a board of at least 150x40 mm.

Tip: if the angle of the roof is small (15-30 degrees), we recommend using a 150x60 mm beam as rafters, installing it “vertically” (figure above), or a metal roofing profile. Snow pressure in winter can be overwhelming.

- We build a system of rafters and battens. By the way, if you are not satisfied with a solid garage, then a wooden frame can also be used for the walls of the garage, followed by upholstering it with the same profile.

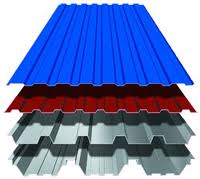

- It is better for you to choose the roof of the garage. You can stop at slate, galvanized steel sheet, corrugated board. We recommend corrugated board, because it wins in relation to other materials and ease of installation, and strength, and service life. Let's consider it.

- Before covering the roof with material, it must be covered with insulation and a vapor barrier. As a heater, you can take mineral wool boards. They are laid in several layers (2-3) with an overlap between the rafters. Do not leave gaps. Reinforced polyethylene can be used as a vapor barrier. We lay it under the insulation with an overlap of 10 centimeters, glue the seam for reliability with adhesive tape.

- Now, when summer heat and winter cold do not penetrate into the garage, we mount the profile.

Choose a color and garage roof cover from the infinite variety of produced material. The profile is laminated, which gives it not only additional strength, but also a chic appearance.

We align the profile along the lower edge of the roof, which we make with an allowance of about 20 cm. If irregularities appear along the profile on the top of the roof, they are easily hidden by the ridge.

As you can see, the question of how to properly roof a garage is not so difficult. A little patience plus a friend to help and the roof will be erected quickly and efficiently.

Did the article help you?