During the construction of the roof, it is very important to correctly calculate and assemble the supporting structures, which must withstand all the loads exerted on the roof. The basis of the supporting structure of roofs are layered and hanging rafters.

During the construction of the roof, it is very important to correctly calculate and assemble the supporting structures, which must withstand all the loads exerted on the roof. The basis of the supporting structure of roofs are layered and hanging rafters.

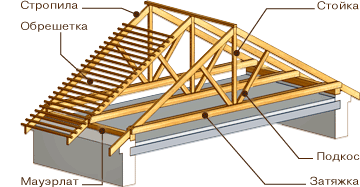

Design of truss systems

Drafting a project roof rafters This is a rather difficult task that requires professional knowledge and experience.

After all, it is necessary to assess the potential load that the roof will experience, to select the optimal cross-section of the rafters, their location step and the shape of the truss.

Naturally, without having the appropriate education, it is extremely difficult to avoid mistakes when drafting projects. Therefore, it is better to leave the experiments, and entrust the design to specialists.

The main points in the preparation of the project are:

- The choice of the type of roof and the angle of inclination of the slopes;

- The choice of material with which the roof will be covered;

- Calculation of the truss system, which is made depending on the decisions made on the first two points, as well as taking into account local climatic conditions (precipitation, wind strength, etc.)

An underestimation of any of the loads or an error in the calculations can lead to such disastrous results as the deformation of the truss system, the destruction of the roofing material, and even the complete collapse of the roof.

The stability and strength of the structure during the construction of pitched roofs is achieved through the correct calculation and proper installation of truss systems.

Scope of hanging rafters

In those buildings that do not have load-bearing internal walls, as a rule, hanging rafters are used. This is a structure that rests on two supports at the edges (for example, on the outer walls of a building), without having a central support.

Rafter legs of this design work in bending and compression, without creating horizontal loads. To reduce the bursting force exerted on the walls by hanging rafters, a puff is used that connects the individual structural elements.

The puff can be made of wood or metal. The location of the tightening is determined based on the design of the roof.

For example, hanging rafters with a puff located at the base are used in the construction of mansard roofs.In this case, the tightening simultaneously performs the functions of a floor beam.

Advice! The higher the puff is located in the system of hanging rafters, the greater the load it experiences. Therefore, when choosing a top-torque option, it is important to use more powerful designs and carefully monitor the reliability of the fasteners.

In the event that hanging rafters are mounted, the width of the span in the building can be from 6 to 10 meters. Rafters are made of wood - timber, logs, boards. To connect the elements, cuts, bolts, steel profiles, dowels, nails are used.

Scope of layered rafters

If the house has an internal main wall, then, as a rule, wooden layered rafters are used for the construction of the roof. The main difference of this design is the presence of an internal support element, which rests on a load-bearing internal wall or column.

Therefore, this design transfers loads only to bending. A rafter roof is lighter and more cost-effective, as it requires less timber for construction.

In houses in which a common roof is installed over several spans, hanging and layered rafters can alternate. In that part of the building where there are no internal supports, a hanging system is used, and in the part where such supports are available, they are layered.

Installation of a hanging rafter system

After installing the Mauerlat, you can proceed with the installation of the truss system. At the first stage of work, it will be necessary to build scaffolding for climbing to the roof, including mobile scaffolding.

This device is useful for lifting workers to the required height and for placing material that should be at hand.

After the issues of safety and convenience of work are resolved (by scaffolding), you can begin to mount hanging truss systems.

For rafters, it is necessary to use a beam with a section of 200 × 50 mm (at least). If you use a material with a smaller cross section, then during operation the rafters are likely to sag.

Before installation, all wooden parts must be treated with an antiseptic solution that prevents the destruction of wood.

Step-by-step procedure for installing rafters from a bar:

- Using pre-built scaffolding, we raise two beams upstairs and connect them.

- We cut a notch on the rafter leg, which will be used for stable support on the Mauerlat.

- On the second rafter leg, it is necessary to cut a similar notch.

- We make notes which rafter leg will be located on the right and which one on the left.

- We install the rafters and connect them.

- In the upper part of the rafter legs, a notch must be made so that the beam is connected not with an overlap, but with an emphasis. The overlap joint is considered unreliable, even if it is well reinforced with nails.

Advice! To properly make the upper notch, you need to connect the bars together and mark the cutout line with a marker. Then make a notch and reconnect the rafters.

- After the first two rafter legs are ready, they need to be well measured and templates made (separately for the right and left "legs"). With the help of such templates, it will be possible to safely prepare the following bars directly on the ground, without raising them to the roof level.

- We install the rafters in place, attaching to the Mauerlat with nails.

- We prepare the second pair of rafter legs, like all subsequent ones, on the ground using the templates made.

- The finished second pair is installed at the opposite end of the roof.

- Between the first and second pair, you need to stretch the twine, which will serve as a level to which you need to navigate when installing the remaining pairs.

- Rafters are installed at a distance that is determined by the project. For example, with a roof slope of 30 degrees, this distance will be approximately 70 cm.

Advice! For the convenience of work, you need to make preliminary notes on the Mauerlat, noting the required distance. Then, according to the finished markings, you can install the rafters.

- The height of the rafter legs is adjustable according to the twine, which was stretched between the first two pairs. If the height is not enough, then the use of wooden spacers can correct the situation.

- The distance between adjacent pairs of rafters at the bottom is regulated according to the markings applied to the Mauerlat, and at the top - using a temporarily installed board, on which a similar marking is applied.

- If the distance between the supporting walls is large enough, then the assembled structure is not stable. Therefore, the question arises, how to tie the rafters? It is necessary to use a puff - a horizontally located beam.

- In the event that the width of the house is significant, then the puff has to be done by joining several boards together. You can fasten the boards with nails, and they are screwed to the rafter legs with bolts or studs.

- When installing puffs, you need to constantly monitor the distance between them. This distance should correspond to the distance between the rafter legs.For control, it is convenient to use boards of small width, on which markings are applied in the same way as on the Mauerlat.

- To stiffen the structure, it is recommended to additionally connect the ridge of the rafter pair and its puff, otherwise the puff may deform under its own weight. Such an operation must be done with each rafter pair!

- At the first stage of construction roof truss system legs are attached to the Mauerlat with nails. After the assembly is completed, it is worth strengthening this place more reliably by installing shank - fastening strips made of thin steel. To do this, the rafter leg is wrapped with a shank, then screws (or nails are driven in) to a depth of about 30 cm through this strip of metal from both sides into the Mauerlat from the inside. Such fastening will prevent the risk of roof destruction in case of strong gusts of wind.

How to build a roof overhang?

During the construction of the rafter system, it often turns out that the length of the beam is only enough for the rafter legs, and in order to arrange an overhang, one has to resort to building up the rafters.

Not a single roof can do without a cornice overhang, this detail is necessary so that the water that has fallen on the roofing in the form of precipitation is safely removed without flowing into internal structures.

Length roof overhang should be at least 40 cm, but in some cases, it is recommended to increase it to 60 cm. Therefore, the rafter legs should be lengthened by this amount. For these purposes, it is convenient to use a board of the required length.

By the way, this solution is even more profitable than using a longer beam.

- Firstly, it is more convenient to work with parts of shorter length;

- Secondly, a longer beam is more expensive;

- Thirdly, if it becomes necessary to repair the overhang, then the additional board can be easily replaced without touching the main system.

conclusions

Thus, hanging rafters are the supporting structure of the roof, which is used in the case of the construction of buildings that do not have internal supports. Subject to the installation rule, such a design is reliable and durable.

Did the article help you?