Now, in the construction of private houses, one of the most popular materials for roofing is metal tiles. When designing a roof, it is imperative to take into account a large number of parameters, one of which is the minimum slope of a metal roof.

Now, in the construction of private houses, one of the most popular materials for roofing is metal tiles. When designing a roof, it is imperative to take into account a large number of parameters, one of which is the minimum slope of a metal roof.

First, let's try to figure out why there is such a parameter as the minimum allowable roof slope.

Any roof generally consists of two important components - the truss system and the roof. The rafter system performs the function of a load-bearing frame on which all layers of the roof are mounted.

The roof protects the interior of the building from the adverse effects of the environment.

Roofing - the top layer of the roofing cake, that is, the part of the roof that directly takes on precipitation, solar radiation and wind.

There are many types of roofing:

- rolled coatings (roofing material and similar materials);

- piece coatings (ceramic tiles, bituminous tiles, slate);

- wavy roofs (slate, euroslate, metal tile, metal profile);

- metal seam roofs;

- membrane roof.

Each of these types has its own characteristics and characteristics.

And one of the most important parameters of each coating is its vertical strength - the ability to withstand the load of rather large volumes of water during heavy rains and the mass of snow lying on the roof.

Now let's turn to the school physics course. It is quite obvious that the greater the slope of any surface, the faster water flows off it. Water drains faster, therefore, less water remains on the roof per unit time.

A simple conclusion - the greater the slope of the roof, the less the mass of water that is on it.

Even more strongly affects the slope of the roof on its ability to be cleared of snow. Snow is not water. This is a loose substance, and with a decrease in the slope of the roof, there comes a certain moment when the snow ceases to descend from the inclined plane and snowdrifts begin to accumulate.

No matter how strong metal roofing no matter how, several tons of snow lying on it can be an unbearable load for the roof and truss frame.

Another factor affecting the ability of the roofing to be cleared of water and snow is the structure of the roof surface.

A smooth metal roof is best cleaned, on which precipitation simply has nothing to linger on. The more transverse elements and roughness on the roof, the stronger the water and snow "cling" to it.

From the above, it follows that for each roofing there is a certain minimum allowable slope, which will ensure its normal cleaning from precipitation and maintaining the integrity of the roof.

Roofing from a metal tile

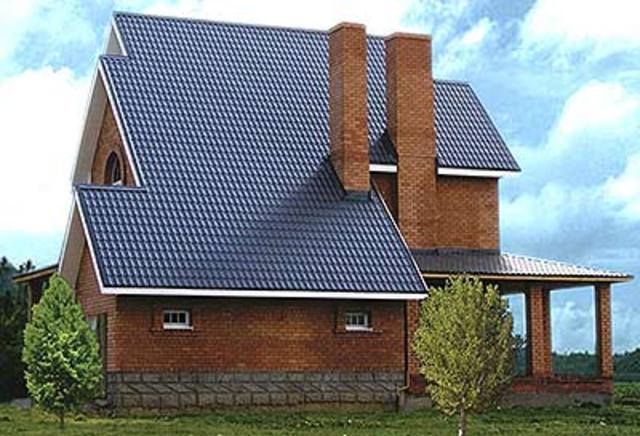

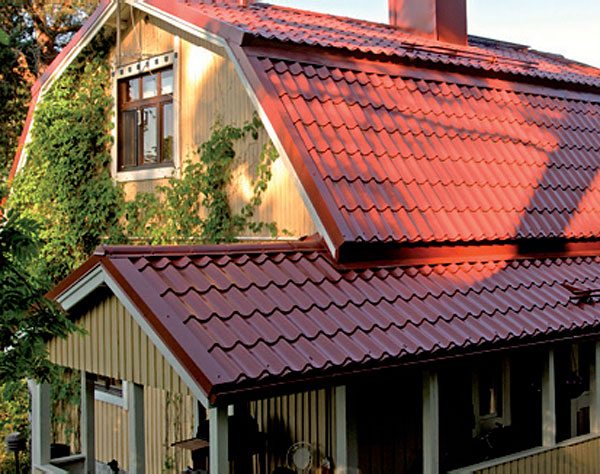

It has already been written above, but I will repeat it again: metal tiles are one of the most popular roofing today. It is widely used in the construction of private houses, cottages, outbuildings and small office buildings.

The reasons for this popularity are quite understandable.

The metal tile has a number of undeniable advantages:

- low weight of one square meter of coverage (up to seven kilograms);

- ease of installation metal roof coverings, allowing you to perform all the work on the overlap yourself without the involvement of specialists;

- attractive appearance and a very wide range of colors;

- high strength material. Despite the fact that the thickness of the sheet is about half a millimeter, due to the profile structure, the metal tile is able to withstand very significant loads;

- low coefficient of thermal expansion allows the use of metal tiles in a very wide temperature range;

- high environmental friendliness;

- relatively low cost;

- good maintainability. In case of minor damage, sections of the roof are subject to straightening and painting.

When choosing a coating for a roof, it is necessary to take into account the inherent disadvantages of a metal tile:

- high noise.Large drops of rain and hailstones very loudly knock on thin metal. To reduce the noise level, additional layers of sound insulation are needed, which increases the overall cost of the roof;

- a large number of trimmings when cutting sheets, especially for roofs with a complex profile;

- the ability of metal to accumulate static electricity leads to the need to ground the roof.

As you can see, the advantages of metal tiles are still greater.

If you have chosen a metal tile as a roof covering for your house, then when designing the roof, you should choose the slope of the roof slopes correctly. According to SNiP, the minimum allowable slope of a metal roof is 12 degrees.

Most manufacturers recommend a slope of at least 14 degrees, but there are exceptions. So, the Finnish manufacturer Ruukki allows laying with a slope of 11 degrees for several models of its products.

So when choosing a specific product, carefully study all the information provided by the manufacturer.

Tip! Reducing the angle of slope allows you to reduce the area of \u200b\u200bthe slope, the amount of materials needed to cover the roof, and, consequently, the cost of the roof as a whole. If for some reason you need to make a roof with a smaller slope, choose a different type of roofing.

Yes, and it makes no sense to block a flat roof with not the cheapest metal tile, if one of its main advantages - an attractive appearance - will not be visible to anyone.

The nuances of installing a metal tile coating

To your attention! Sheets of a metal tile during installation keep within on a roof from left to right. Each sheet is fastened to the crate with the help of special screws - self-tapping screws with a rubber insulating gasket. With a slope length of more than 6 meters, it is recommended to mount it in a composite way due to the difficulties with transporting and installing sheets that are too long.

When mounting with self-tapping screws, it is strictly prohibited:

- screw the screws through the sections of the profile, except for the lowest part of the wave;

- use self-tapping screws without an insulating rubber gasket;

- bait self-tapping screws before tightening with hammer blows.

A non-trivial task is the installation of a valley with a metal roof.

roof lathing under the valley it is carried out only in a continuous version, not less than 40-50 cm from the center of the gutter. The lower metal groove is attached to the crate with clamps.

Then sheets of roofing metal tiles are inserted into it so that at least 10 cm remain until the middle of the groove. The upper groove is laid on top of the profile waves and screwed to them with self-tapping screws. In this case, damage to the lower chute is strictly not allowed.

Another interesting innovation of recent years has been the introduction by large manufacturers of the tradition of printing instructions that describe in detail all the stages of installation of their products.

These instructions are published in the form of paper catalogs with an extended reference part, electronically sent to all dealers and posted for free access on the company's websites.

If you are interested in the installation of metal roofing, the instructions can be sent specifically to you upon request by most manufacturers.

Such openness is a good marketing ploy, as it additionally attracts not only professional builders, but also those who want to build their own house with their own hands.

If such an amateur builder has detailed instructions for installing a metal roof from the manufacturer, then the likelihood of making serious mistakes when designing or installing a roof is significantly reduced.

For professional builders, these instructions provide a lot of background information that makes it easier to draw up a roof project.

In such publications, the construction technology of the truss frame and roof is described step by step, providing each step with a detailed description, photographs and drawings.

And at the end of the article, a few tips on roof design, transportation, storage and installation of metal tiles:

- cut metal sheets with metal shears, a guillotine or other tools, provided that during cutting the surface does not heat up and sparks are formed that can damage the polymer coating;

- any scratches found during construction should be immediately painted over with special paint to avoid corrosion;

- to move along the surface of the metal tile during the work should be in soft shoes, stepping exclusively on the concave waves at the points of attachment to the crate, so as not to damage the profile;

- chips and any debris from the surface should be removed only with soft brushes;

- three months after the start of operation of the finished roof, it is necessary to tighten all the fixing screws.

Did the article help you?