As a way of arranging the roof, many today choose to cover the roof with metal tiles with their own hands. Due to its properties, the metal tile as a roofing is distinguished by reliability and durability - which means that once you equip the roof, you can forget about worrying about its condition for many years.

As a way of arranging the roof, many today choose to cover the roof with metal tiles with their own hands. Due to its properties, the metal tile as a roofing is distinguished by reliability and durability - which means that once you equip the roof, you can forget about worrying about its condition for many years.

In addition, metal roofs have an attractive appearance - their bright color practically does not fade over the years, so your house will look like new even after a couple of decades after the roof has been renovated.

The structure of the metal tile

What is a metal tile?

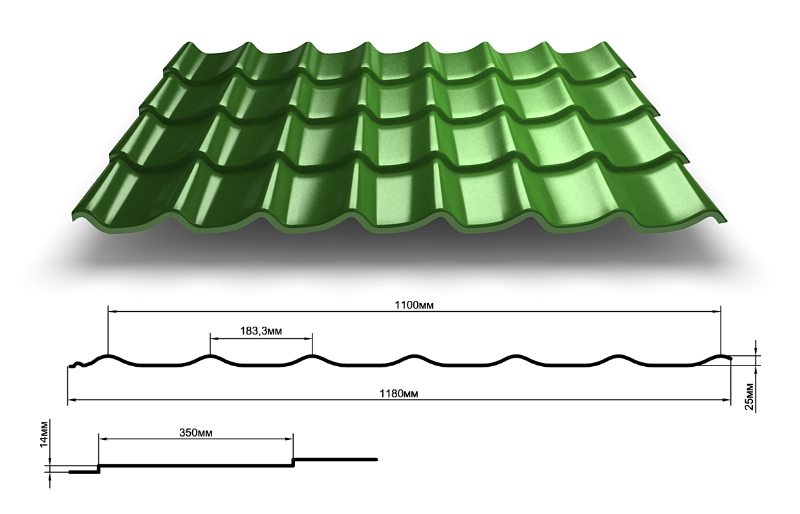

Excellent consumer properties of metal tiles (strength, reliability, durability, corrosion resistance) are explained by its multilayer structure.

The basis of a metal tile sheet is a steel sheet (metal thickness - from 0.4 to 0.7 mm, depending on the brand). To prevent corrosion, the metal is covered with a passivating layer, which includes aluminum-zinc compounds.

Several protective layers are applied over the passivation, and then a polymer coating.

Depending on the type of polymer used, different types of roof tiles are distinguished: metal tiles with a polyester coating, metal tiles with a matte polyester coating, and also with a plastisol coating.

On top of the polymer layer, some manufacturers apply a layer of protective varnish, which increases the water-repellent properties of the metal tile, and also reduces the effect of ultraviolet rays on the material.

As a result, the metal tile covered with such a varnish burns out and discolors more slowly.

Roof preparation

Laying metal tiles on the roof requires a number of preparatory work.

The preparation of the roof for laying metal tiles includes:

- Arrangement of waterproofing

- The construction of the crate

- waterproofing do-it-yourself metal tile roofing it is created directly on top of the roof rafters (in this case, the distance between the rafter legs should be within 1.2 -1.5 meters). For the arrangement of a waterproofing layer under a roof made of metal, it is recommended to use specialized waterproofing materials with an absorbent layer.The film for waterproofing is laid with an absorbent composition towards the room, while the sagging of the film in the free areas between the rafters should not exceed 20 mm. For ease of installation, most manufacturers put markings along the edges of the film indicating the amount of overlap.

- The waterproofing film is fixed to the rafters using a stapler with galvanized staples. It is also allowed to fasten the film to the rafters using galvanized nails. We fasten the waterproofing material in the direction from the bottom up: first we fix the waterproofing near the edging, and only then we rise to the roof ridge.

Note! If it is planned to insulate the roof, then a layer of vapor barrier material is also laid along with the waterproofing layer. This will prevent the formation of condensate in the thickness of the roof and protect the heat-insulating material from getting wet.

- When the waterproofing work is completed, the technology for covering the roof with metal tiles provides for the construction of a crate. The crate is a frame of wooden beams rigidly fixed to the rafters on top of the waterproofing, to which sheets of metal tiles are directly attached.

- For the construction of the crate, we use wooden beams or thick boards treated with an antiseptic in order to prevent the wood from rotting when wet. You can also use a perforated galvanized steel profile for the crate.

- We lay the crate on top of the equipped waterproofing, fixing it through 50 mm bars - the so-called counter-battens. The system of counter-rails not only protects the waterproofing from damage, but also provides roof ventilation, preventing condensation.

After the preliminary installation of the roof under the metal tile is completed, you can proceed directly to the installation work. However, very often it is necessary to adjust the sheets of metal tiles to the required configuration.

Cutting of metal tiles

As practice shows, it is better to trim the metal tile to size before lifting the metal tile onto the roof. However, in some cases, corrective pruning is allowed immediately before fixation.

Strictly speaking, it is undesirable to cut sheets of metal tiles - when cutting, the integrity of the protective layers is violated, the metal is exposed - and therefore, there are prerequisites for corrosion on a metal roof.

And yet, if cutting is necessary (for example, when arranging the roof of a sloping roof), then the following rules should be observed:

For cutting, use a circular saw or a jigsaw. The use of a grinder is highly undesirable!

- A cut with an open metal of the inner layer must be covered with paint to protect against corrosion.

- Sheets of tiles with cut sections are laid with a cut under the whole sheets, minimizing the contact of the cut line with atmospheric precipitation.

- After the preliminary trimming is completed, we move to the roof and begin the installation of the roof directly.

Installation of metal roofing

If the pruning is done correctly and the crate is reliable, then the installation of the roof should not present any particular difficulties:

- To fix the metal tiles on the beams of the crate, we use self-tapping screws for metal (4.5x25 and 4.5x35mm) with an octagonal head.To ensure a more secure fixation, we supply each self-tapping screw with a sealing washer.

- Fixation of sheets of roofing material is carried out with preliminary drilling of metal tiles. It is not necessary to tighten self-tapping screws "for profit" - the risk of damage to the protective layers is high. Consumption of self-tapping screws for fixing sheets of metal tiles is 7-10 pcs / m2, however, for roofs of irregular shape, the flow rate can almost double.

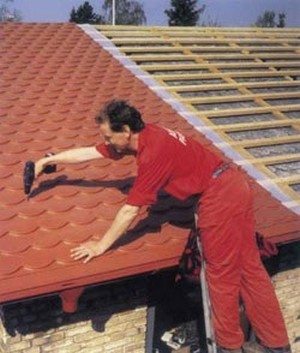

- Mounting gable roof roof, we start laying sheets of roofing material from one of the ends. If the roof has a tent configuration, then we move from top to bottom, gradually shifting to the sides.

Roofing

- The metal tile can be laid both from the right and from the left end of the roof. Moreover, if laying is done on the right, then the edge of the sheet is laid on top of the fixed one, and if on the left, then the sheet is wound under the already laid one.

- We align the sheets of metal tiles along the cornice and along the length, and then proceed to their fixation. Additionally, we fix the sheets in the overlap zone - so our roof will be even stronger and more reliable.

- After the tiles on the slopes are laid, we proceed to the installation of the final elements. On the ridge of the roof we fill the ridge bar, to which we fasten the ridge elements of the metal tile with self-tapping screws. In places where the roof adjoins vertical surfaces, we lay the so-called butt strips. In these places it is also advisable to lay an additional layer of waterproofing.

It is better to master the technique of arranging a roof from a metal tile on roofs of simple shapes. But if you once cope with the arrangement of a simple roof, then you will be able to handle a variety of types of metal roofs!

Did the article help you?