The roof is the final stage in the construction of a country house. The reliability of the entire building, as well as the comfortable living of residents, depends on how competently the roof structure and the materials from which it is built are chosen. In order not to make a mistake in choosing the design and roofing materials for the construction of the roof, we recommend that you contact the specialists: ursa pitched roof. In our article we will talk about the types of pitched roofs, their design features.

The roof is the final stage in the construction of a country house. The reliability of the entire building, as well as the comfortable living of residents, depends on how competently the roof structure and the materials from which it is built are chosen. In order not to make a mistake in choosing the design and roofing materials for the construction of the roof, we recommend that you contact the specialists: ursa pitched roof. In our article we will talk about the types of pitched roofs, their design features.

Pitched roof: basic concept

The pitched roof got its name due to the fact that it consists of slopes - these are planes that have a certain slope angle (the minimum slope of the pitched roof is 10). Pitched roofs have two design solutions:

- attic (separate);

- barren (combined).

The pitched roof of the attic type has a non-residential premises (attic), which is located between the attic floor and the roof. The load-bearing elements of non-attic roofs are the ceiling for the upper floor of the house.

The main components of a pitched roof:

- Structural part.

- Roof.

The design of a pitched roof consists of a supporting frame of the roof, the purpose of which is to take the load from the roof itself and all kinds of precipitation.

Roofing is a roofing material that protects the roof and the entire house from negative environmental factors. Pitched roofs have a certain slope, it is needed in order to remove atmospheric precipitation from the roof.

The slope of the roof is expressed both in degrees and as a percentage. It depends on many factors:

- From the amount of snow cover in the region. The more snow cover, the greater the slope angle should be.

- From the material of the roof. Each type of roofing material is designed for a certain angle of inclination. This can be found in the instructions that come with the roofing material.

- From the architectural features of the house. Very often the architectural volume of a building is decided by its roof. So, in the case when the developer decided to cover a flat roof with ceramic tiles, the project architect is obliged to point out his mistake, and what such a mistake is fraught with - the complete destruction of the roofing material.

The main types of pitched roofs

Pitched roofs, depending on the type and number of slopes, are:

- Shed - roofs have one slope from wall to wall. Such roofs are used for urban buildings where drainage and snow dumping are prohibited. In individual construction, such roofs are used for garages and sheds.

- Gable roof - a roof with two slopes. This roof option is the most popular, it can be used in the construction of buildings of various designs and scales.

- Four-pitched (they are also called half-hip) - the roofs have four slopes. Half-hipped roofs are usually used in rural or summer cottage construction.

- Four-pitched tented roofs have four slopes, their tops converge at a single point. Such roofs are usually built for buildings with a polygonal or square plan.

- Spire-shaped - the roofs have several steep slopes in the form of a triangle, which are connected at one vertex, overlapping the towers, bay windows are round wall structures.

How to choose the design of a pitched attic roof?

In order for the pitched roofs of the attic type to have the necessary design, you need to know some features:

- In order for the rafter leg to withstand the total load of the entire roof, it is necessary that it has a massive section, in this case the overlapped span will be large.

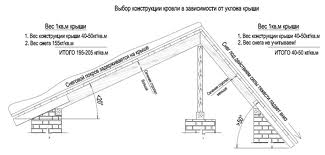

- Pitched roof slope. If the roof has roof pitch more than 50 degrees, then the snow cover on it will not linger, respectively, there will be less load on the roof structure. Therefore, on such a roof, the cross section of the rafters can be reduced. So, when choosing a sloping roof with a slope angle of 20, you need to increase the cross section of the rafters several times, since the snow load on a flat roof increases several times.

- What are the requirements for the durability of the structure. In terms of durability, the roof must be equal to the house. That is, if the house lasts at least 100 years, then the roof should last the same amount.

- An integral attribute of the truss system is its fire resistance. In accordance with sanitary standards, an attic-type pitched roof device must have an appropriate bearing capacity. And this means that the roof must support its own weight, the weight of snow and roofing material. When exposed to open fire, the roof must maintain its integrity for 15-45 minutes (depending on the material). To achieve such a fire resistance limit, you need to know: a structure with a large cross section will withstand the effects of fire much longer if it has high-quality fire protection (treated with flame retardants, cement-sand plaster, non-combustible mats, protective paints).

- Thermal properties of the roof. The more the roof is insulated, the more it weighs, so the cross section of its structure must be large.

Service life of a roof made of different materials

Consider how many years a pitched roof made of different materials will last, subject to proper care and proper operation, without major repairs:

- Wooden roofs - from 20 to 30 years.

- Reinforced concrete - from 30 to 50 years.

- Metal - from 30 to 50 years.

These values are calculated by design engineers, however, for example, a wooden roof has life examples of operation for more than one hundred years.

The main types of pitched roof construction

Depending on the purpose of the roof, the following types of roof construction are distinguished:

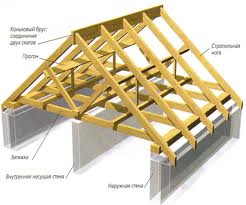

- The structure of the roof is pitched wood. This design is most common in the construction of low-rise buildings. It consists of rafters (hanging and layered) and trusses. The device of the truss system: rafters, rafter legs, mauerlat, racks, ties, crate. Hanging truss systems are used in houses where there is no middle load-bearing wall on which the roof rests. Wooden trusses are almost never used in private construction. They are used in large-scale industrial construction, as well as in frame housing construction using Canadian technology. The wooden structure has the following advantages: durability, relative cheapness, environmental friendliness. But it also has disadvantages: fire hazard, susceptible to corrosion, rotting and exposure to various microorganisms.

- Metal-wood construction. This design is combined, it has elements of wood and metal in the form of trusses, arches and frames and can cover spans up to 20 m. Its upper belts are usually made from glued wood, the lower elements are made from profiles of a periodic section or reinforcement. Thus, metal elements work in tension, and wood works in compression. Metal-wood structures in private construction are used very rarely, mainly due to excessive high cost. Although wealthy people are attracted by excellent decorative properties. In public construction, such structures are used in the construction of swimming pools, industrial enterprises with special working conditions.

- The device of the roof is pitched with reinforced concrete structures.Prefabricated reinforced concrete rafters made in the factory have gained particular popularity recently. The rafters have a tee or rectangular section, they are installed on the ridge run and the walls, interconnected by embedded welded parts. The use of such a design in private housing construction is very problematic, since special equipment and embedded parts are needed. They are most often used in the construction of large-scale agricultural structures (granaries, warehouses, transport depots). The main advantage of reinforced concrete structures: high strength, durability, ease of maintenance. Negative sides: heavy weight, the use of special equipment during installation and delivery, the complexity of combining concrete and wood.

The issue of a pitched roof device depends on many factors, including financial capabilities. It is up to you to contact a construction company or, armed with special knowledge, build a roof yourself.

Design features of a pitched roof

Any pitched roof, no matter how many slopes it has, consists of:

- Comb or skate.

- Inclined rib.

- Roof tops.

- Groove.

- Cornice overhang.

- Gable, gable wall.

The installation of a pitched roof depends on the features of its internal structures (read about them above) and external ones. The task of the internal bearing is to ensure the reliability of maintaining the roof (load-bearing capacity).

Attention! Only after the internal structure of the truss system is determined, it is possible to determine the method of solving roofing work.

The method of performing roofing work directly depends on what angle of the roof slope. Roofs with a steeper slope require certain methods of laying roofing, with overlaps.

Moreover, it is important to know that the smaller the roof roof pitch angle, the more it is necessary to carry out overlaps and overlays of side joints.

Steeper roofs can be made with minimal overlap, but it should not be completely neglected, since snow may be blocked in winter.

In our article, we talked about what a pitched roof is, what its varieties and design features are.

Did the article help you?