A sloping roof (sometimes also called a sloping mansard roof) is one of the most difficult types of roofing to design and build. And yet, the broken type roof is very popular - if only by erecting such a roof you get an additional room, which is quite comparable in area to the area of the house itself.

A sloping roof (sometimes also called a sloping mansard roof) is one of the most difficult types of roofing to design and build. And yet, the broken type roof is very popular - if only by erecting such a roof you get an additional room, which is quite comparable in area to the area of the house itself.

In this article, we will try to deal with all the nuances of the construction of sloping roofs, from planning to roofing. gable roofs.

What is a broken type roof?

Broken roofs, which are widespread today in private construction, are mansard roofs with four slopes.

And despite the fact that from a design point of view, classic gable and hipped roofs are more expressive, the construction of a sloping roof allows more efficient use of the internal attic space.

So if you prefer high functionality, and you need the most spacious roof - a broken structure is exactly the choice you need.

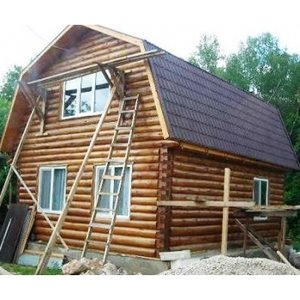

However, from a design point of view, such a roof is not at all bad. A house with a sloping roof looks very solid, and if you emphasize this by using the appropriate roofing material, then your estate will become a small masterpiece.

Where are broken roofs used? First of all broken mansard roof built on fairly wide houses.

The optimal width of the building for the installation of roof structures of a broken type is about 6 meters: the attic space is already not used so efficiently, wider it is more difficult to design and install a reliable and efficient truss system.

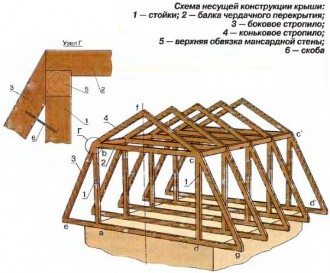

Note! Even despite the impressive dimensions of the supporting structures (you can see them in the images), an independent construction of a broken roof is quite possible. The thing is that the rafter roof system of a broken type is most often assembled according to a modular principle: individual elements are prepared for assembly on the ground, rise up and are only mounted there.So you probably won't need heavy construction equipment.

Materials and tools

What is needed for the self-construction of a sloping roof:

- First of all, it is, of course, wood. The main elements for the construction of a sloping roof are timber and a thick edged board made of coniferous wood. Mauerlat (supporting bar along the perimeter of the building), rafter legs and braces will be made from timber. For the manufacture of the remaining elements of the truss system, you will need an edged board.

- Thinner wooden slats will be needed to create battens and counter battens for roofing material.

- To connect the rafters of a sloping roof, you will need a fairly thick plywood.

- The beams and boards are connected using steel brackets, studs with a diameter of 8-12 mm, self-tapping screws and staples made of galvanized metal. Also, self-tapping screws and nails will be needed to fasten the lathing bars to the rafters and to fix the roofing material (for example, metal tiles or ondulin).

- You will also need waterproofing material, insulation (and in this case, roof insulation is mandatory - otherwise it will be very cold in the attic, and you will not be able to heat it) and the actual roofing material.

- You are unlikely to need special tools for the construction of such a roof, however, a set of carpentry and joinery tools is required.

Note! When working at height, in no case should you neglect mounting and safety belts.So during all work it is necessary to strictly observe the safety regulations, and use all the provided personal protective equipment.

Protecting wood from fire and decay

Before you make a sloping roof (or rather, its rafter part), it is necessary to take preventive measures to protect the wood of rafters, beams and girders from decay and fire.

To do this, even before climbing to the roof, all wooden parts are treated with fire-fighting compounds and antiseptics that prevent the development of putrefactive processes.

For processing wood we use a wide flat brush. We apply the composition in two steps, waiting for the complete drying of the previous layer - this way we will ensure the deepest penetration of the protective composition into the pores of the wood.

Note! When applying protective compositions, the eyes and respiratory organs must be protected by goggles and a respirator. The application of antiseptics and antipyretics by spraying from a spray gun is possible, but undesirable - despite the significant acceleration of work, the quality and depth of impregnation suffer greatly.

It is also possible to treat the already finished rafter part with a protective compound, however, in this case, it is necessary to coat the joints of the wooden parts with a very high quality, if necessary, releasing the stud clamp.

The rafter part of the sloping roof

After all the materials are ready, we proceed to the construction of the rafters - the skeleton of our future roof.

The truss structure of a sloping roof is erected as follows:

- According to the drawing of a sloping roof, we make a template for the main parts.You can, of course, do without templates - but it’s easier with them: you don’t need to calculate the trimming angle for each rafter to the nearest degree.

- According to the template, we cut out the details of the rafter part and raise them to the installation site. For the convenience of the sections of the four-pitched truss system, we expose in turn - first we attach the side sections to the Mauerlat, fixing their position with technological stops, and then we attach the upper sections to them, fastening them at the top.

- To fix the corners and securely fix them (the complex geometry of a sloping roof depends on this), we use plywood pads. We fix the plywood to the rafters with the help of self-tapping screws.

- The upper bar-run, of this design. as a hip standard, we connect with the upper sections, as well as with the lower faces of the puffs of the gable parts. After installing the running beam, we fix the entire truss structure by installing and fixing the braces.

- After installing the braces, we reinforce the side sections with vertical posts. For the manufacture of racks we use a beam of coniferous wood.

Warming and waterproofing

Further, our sloping roof requires the arrangement of an insulating layer and waterproofing.

It is preferable to use roofing insulation, as it is most effective in insulating the ceiling and walls of our attic.

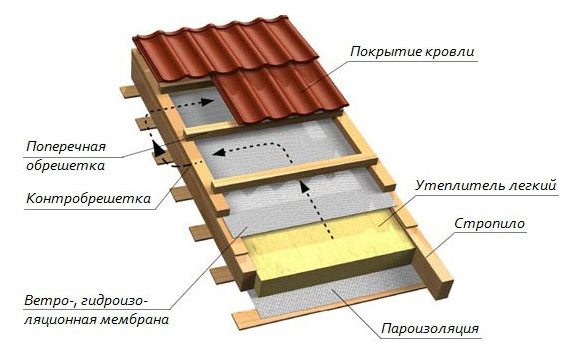

On top of the rafters, it is mandatory to lay waterproofing and vapor barrier materials - such a broken roof device will not only protect it from leaks, but also prevent condensation in the under-roof space, which negatively affects the attic microclimate and the effectiveness of the insulation.

We attach hydro- and vapor barrier materials to the rafters with galvanized metal staples using a construction stapler. It is optimal if the waterproofing panels are overlapped, without sagging (in extreme cases, let's say the sag is no more than 20 mm).

Roofing

When the work on insulation and waterproofing is completed, you can proceed to the final stage - the direct laying of the roofing material.

Despite the fact that houses with sloping roofs have slopes with different angles, the technology for laying roofs for sloping roofs is practically the same as the traditional one.

Most types of roofing (for example, the same metal tile) require the construction of a crate on top of the truss system.

We make the crate from a durable, even and dry wooden beam, which we stuff onto an insulated and waterproofed roof through the so-called counter-rails - backing bars. The system of underlay bars not only preserves the integrity of the waterproofing, but also provides roof ventilation.

When creating a crate for a roof, it is necessary to monitor the straightness of its sections, since even a slight deflection or curvature can subsequently lead to a violation of the tightness of the roof.

Naturally, all of the above is only the most general information about the technology of erecting mansard sloping roofs. As mentioned at the beginning, a sloping roof is one of the most difficult types of roofing.

However, the benefits that it provides more than justify all the efforts to build it.

Did the article help you?