The final stage of building a house includes the final selection of roofing and its installation. Most often, the construction of the roof is trusted by specialists, since this type of work is the most responsible and unsafe. To date, metal roofing has become a popular type of roofing in private housing construction. The simplicity of its installation allows you to cover the roof yourself, which saves a lot of money.

The final stage of building a house includes the final selection of roofing and its installation. Most often, the construction of the roof is trusted by specialists, since this type of work is the most responsible and unsafe. To date, metal roofing has become a popular type of roofing in private housing construction. The simplicity of its installation allows you to cover the roof yourself, which saves a lot of money.

Metal tile for a simple roof structure

It is best to cover with metal tiles roofs with a slope, when the slope of the slope is not less than 14 degrees.It is preferable that the roof be geometrically simple, since there will be no need to cut the material itself and there will be no unclaimed scraps.

Why extra spending when we make the roof ourselves and for ourselves?

When purchasing the right amount of metal tiles, you must:

- accurately measure the roof;

- it is important that the sheet is 4 cm longer than the roof so that its end overlaps the eaves; such an arrangement will create a ventilated space on the ridge;

- it is necessary to carefully measure the parameters of the future roof, including diagonally;

- before you start to cover the roof, it is useful to make sure that it does not have bumps;

- if they are, and it is not possible to align, you can lay the tiles so that the lower edge of the crate itself coincides completely with the overhang line of the sheet.

It is impossible to install the roof with your own hands without a special tool:

- metal scissors,

- electric drill,

- grinders,

- hacksaws.

You need to start with the installation of the truss system. The rafters are beams and serve as a frame for the future roof. According to the established standard, the truss system provides a pressure of 200 kg per square meter.

Advice. Regardless of the characteristics of the roofing material itself, this requirement is mandatory so that the roof can withstand the pressure of the wind, the weight of the snow that has fallen.

- Before starting the installation of the truss system, the load-bearing walls are screeded.

- Then the waterproofing, the longitudinal beam and the bed are laid.

- A rafter support system is assembled from struts, girders and racks.

- Next comes the installation of the rafters themselves, starting with the extreme ones, ending with the intermediate ones.

A good help can be a video on how to make a roof with your own hands. No roof is laid on a bare rafter "skeleton": a crate is needed.

It is made from various materials, most often from wood. Wooden boards are attached to the rafters with nails. The parameters of the boards of the crate depend on the material that will be used for the roof.

For roofs made of metal a base from a weaving board is required. The thickness is calculated individually, but the extreme long boards are usually 10 mm thicker.

Based on the value of the transverse pitch of the profile (350-400 mm), the distance between the boards is calculated. The board that goes beyond the cornice, as well as following it, is placed in increments of a smaller size (300-350 mm).

Features of the gable roof lining

Sheets of metal tiles are attached to the crate.

Advice. When lining a gable roof, you should start from the end, and in the case of a hipped roof, start from the highest point, gradually going down.

- The metal tile is always laid with an overlap, the previous sheet is covered with another sheet on top.

- Between themselves, the sheets of metal are fastened with self-tapping screws, then - to the ridge with screws.

- End strips are installed from the bottom up along the frontal surfaces of the roof, and the ends of the sheets of metal tiles are covered.

- End strips are fastened with self-tapping screws, which are screwed to the crate and waves (extreme) of the tile sheet.

- When the end strips are installed, ridge strips are installed, which are fixed in the upper part of every second wave of the metal tile. They are responsible for the facade of the house. These elements are also screwed with screws.

- After the planks are installed in length, the overlap in width is approximately 10 cm.

- At the junction of the slopes, the installation of the valley is carried out. There are two copies of them, the lower one is placed on top of the cornice strip, directly on the crate, and the one on top is placed on top of the wave of the tile sheet.

- Next, the installation of pipes and drains of the gutters is carried out.

Who is interested in how to make a roof at home with their own hands - the video demonstrates the scheme proposed by the manufacturers. It must be remembered that the hooks for mounting the system must be attached to the crate even before the installation of the metal tile.

If desired, you can install a lightning rod.

Roof made of ordinary slate

For those who want to figure out how to cover a roof, the more familiar technology is no less interesting - laying slate. It is willingly used when a do-it-yourself massandra roof is needed.

Standard slate roof pre-coated with acrylic paint specifically for painting slate. Without this, it will actively absorb moisture and eventually collapse. In its pure form, slate can last 15-20 years. Painted slate is 3-5 times stronger and more durable.

Why? When the wet slate freezes, the water in the microcracks will expand them and gradually destroy the structure of the slate. The painted material is protected from water in microcracks (they are filled with paint). It is enough to inspect a slate roof once every two to three years, tinting as necessary.

For these purposes, you need to take care of safe access to the roof, you need the so-called roof ladder.

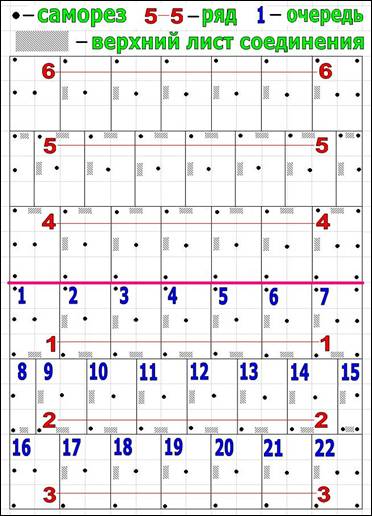

In a modern house, each slope is covered with three rows of slate. The middle row starts from the edge not with a whole, but with a half-sheet of slate (cut in length).

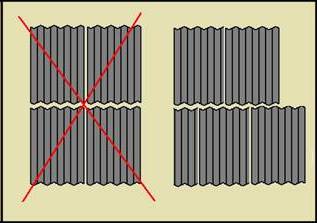

If joined in another way, then 4 sheets of slate lie at the corners of each other. Gathered at one point, they form visible gaps and create an unstable connection.

Do not look for instructions on how to make a roof with your own hands - the video demonstrates how to calculate the amount of slate per house and how many of them need to be cut.They cut the slate with a grinder, this work takes an hour.

One sheet is cut in half - at the rate of 4 waves in a half (eight-wave slate). Two sheets are cut so that parts of 5 waves and 3 waves are formed. Parts with 5 waves should have a small wave around the edge.

In the factory slate, the last wave is smaller than the rest - it is designed specifically for docking. When there is a combined roof, then the slate is also laid in such a way that a small wave remains attached under a large subsequent sheet (small + small is not good).

After cutting, you get 6 pieces of slate: two 5-wave (they begin to cover the middle rows), two in four waves (they finish covering the middle rows) and two in three waves (spare).

The slate is attached with roofing screws over the wave (if you attach it at the bottom of the wave, water will flow under the roof). The self-tapping screw enters the center (or slightly higher) of the crate board. With a Pobedite drill D 6-7 mm, a hole is drilled in the slate for a self-tapping screw. Builders can pierce the slate with a nail, which creates many microcracks (this will cause the destruction of the entire slate in 2-3 years).

Advice. Underestimating the importance of the crate, some builders try to save on it by using low-quality wood. The bars of the crate turn into dust, they no longer hold the slate, and the entire slope can move out. It is necessary to choose the bars of the crate with great care.

If you are watching tutorials on how to put a roof on, the video will draw your attention to which direction the overlap of the slate and ridge metal sheets is.

Advice. Choose the side where the winds most often blow.If this direction is not taken into account, then in rain with a strong wind, water is collected in the space between the sheets, and leads to constant wetting of the crate.

It is convenient to fasten the slate, starting from the top row. The upper edge of the slate row is tied with a marking thread to the extreme rafters, then the lower edge is marked.

The upper edges of both slopes gable roof are at the same height and do not interfere with each other. Between the roof slopes, the distance between the edges of the uppermost slate sheets must be kept from 100 to 200 mm.

When learning how to make a roof at home, video tutorials are a must. They illustrate all possible construction situations and help to find the right solution.

- Let's say the wind usually blows from the right, so you need to cover the roof on the left.

- The very first block of painted slate is attached to the crate with a self-tapping screw, which is screwed into the center of the sheet.

- After that, the center of the left edge is fixed with the next self-tapping screw.

- The second sheet in the top row is superimposed on the extreme wave of the previous sheet and is attached to the crate with a self-tapping screw.

- All subsequent sheets of slate in the top row are also fixed. The slate sheet is held first on one self-tapping screw.

- From half a sheet of 5 waves, the second row of slate is attached. To secure this half of the sheet, it is slipped under the first sheet in the top row, with an overlap of 100-150 mm. ).

- The center of the left edge is fixed with screws.

- Then, with one self-tapping screw, the first sheet in the upper row is connected to the first sheet of the second row. It is necessary to drill a through hole of two sheets of slate (left-upper lower and left-lower corner of the upper).With an overlap of 150 mm, the offset for the screw-in screw is 75 mm or half of the overlap.

- The second block of the middle row is superimposed on the extreme wave (small) of the first block of the second row and is slipped 150 mm under the first and second slate blocks in the top row. A self-tapping screw is screwed in the center of the second block already in the middle row.

- 10. Now you need to fasten 3 sheets of slate with one self-tapping screw. A self-tapping screw is screwed through three sheets into the crate and the third sheet of the middle block is laid.

- 11. Further - the same scheme. The last is a half-sheet with 4 waves.

- The third row is laid similarly, the only difference is that we start laying from a whole sheet.

- The bottom in the third row is fastened with self-tapping screws.

- Another slope of the gable roof is already spreading on the right, so that the overlap of the slate sheets is in one direction on both slopes.

- After that, the ridge strip is installed.

Advice. To isolate the roof from rain and snow, we foam the joints of slate sheets, as well as slate waves, so that snow does not accumulate between the slate masonry and the strip on the ridge.

Did the article help you?