The roof ridge is a horizontal upper edge of the roof, which is formed by the intersection of the roof slopes, as well as various elements located on this edge. This article will talk about how to make a roof ridge with your own hands, as well as how to correctly calculate its height and ventilate the under-roof space.

The roof ridge is a horizontal upper edge of the roof, which is formed by the intersection of the roof slopes, as well as various elements located on this edge. This article will talk about how to make a roof ridge with your own hands, as well as how to correctly calculate its height and ventilate the under-roof space.

In the recent past, after the roof was erected, the ridge was covered with special asbestos-cement materials; roofing iron is also not often used to cover the ridge.

The most acceptable and common is the use of galvanized iron for the manufacture of a ridge for such a structure as four-pitched hip roof.

For this, ready-made galvanized corners about two meters long are used, which can be purchased at any building materials store or made independently from sheet scraps.

The manufacture of the corner from which the roof ridge is made is carried out in the following way: the sheet is cut along a pre-marked line on a flat surface and tapped with a mallet (a hammer can damage the zinc coating of the sheet) until the required profile is obtained.

It is recommended to choose the following strip sizes: width - 240-300 millimeters, length - 2000 millimeters for the ridge of a gable mansard roof.

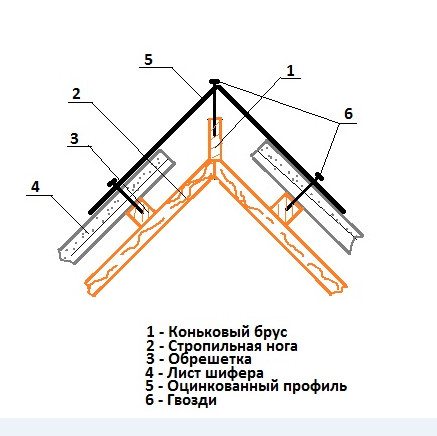

The figure schematically shows the mounting of the ridge on the roof. It should be borne in mind that the overlapping of each other with the elements of the ridge should be 10 centimeters, and the side of the used corner should be 12-15.

The nails must pass through the waves of the slate and fall into the crate. For this, an additional crate beam is often stuffed in the ridge area. If necessary, you can refuse to use a ridge beam by nailing a corner of a galvanized profile directly to the frame of the crate.

When installing the ridge on the roof, they used to cover the gaps between the roof covering and the metal corner with a mortar, and today their blowing with mounting foam is becoming more common.

Self-installation of the roof ridge is a fairly simple procedure that requires compliance with safety regulations when working at a significant height.

Roof ridge height calculation

Before you make a ridge on the roof, you should find out the exact heights of both the ridge itself and the ridge run.

The calculation of the height of the first, which depends primarily on the angle of inclination of the slope and the roof frame, as well as on the material chosen for covering the roof, should be discussed in more detail.

After the choice of roofing material is made, the installation of the roof ridge can be started. To do this, you need to calculate the height.

This procedure consists of the following steps:

- First of all, at least two units of special ridge tiles are laid, resting on both sides of the roof slopes, after which the distance between the upper edge of the tile and the inner edge from the narrowest end is measured. The upper edge consists of bars, also called a counter-lattice, and are interconnected at the minimum possible distance, which is sometimes called a ridge air element.

- It is also necessary to measure the distance from the upper part of the holder of the ridge beam inserted into the mount to the point of inflection of the fastening line, and then make the holder or fastener. After that, with the help of nails, the upper bar of the ridge is nailed to the central part of the counter-lattice.

- Fasteners are also mounted at the beginning and end of the skate itself, after which a special mounting cord is pulled. In the absence of such, you can use a standard fishing line of a sufficiently large thickness. This cord is designed to properly lay the ridge run.

- They make installation in the holders and fastenings of the ridge beam, fixing it with nails made of high quality stainless or galvanized steel.

Important: the device of the roof ridge requires the obligatory presence of lightweight side tiles designed to cover the ridge run after the completion of the above work.

To prevent the penetration of steam and moisture into the space under the ridge, as well as to ensure its acceptable temperature, it is recommended to perform heat, sound and waterproofing.

If the installation of the ridges is done correctly, then all the joints and seams formed when covering the roof slopes must be completely covered by the elements of the ridge run.

It should also be remembered that the ridge roof is equipped with a ventilation compartment, in the absence of which a constant accumulation of condensate will begin, even if there is a waterproofing layer.

The ventilation box can be either purchased ready-made or made independently. Their installation is carried out using an adhesive mixture or special fasteners.

Important: the ventilation duct should be glued only to clean and dry roofing material, and it is undesirable to do this in cold or hot weather.

After the calculation of the height of the roof ridge is completed and all work is completed, the ridge run is installed, the best material for the manufacture of which is considered to be a special ridge tile, which also serves as a decoration for the roof ridge.

Installation of such tiles should be done starting from the leeward side of the house in order to prevent precipitation from entering and blowing air through the joints of the roofing material.

First, clamps are installed on which the tiles are laid and nailed with galvanized nails or screwed with screws or self-tapping screws.

Roof ridge ventilation device

1. Vapor barrier.

2. Insulation.

3. Waterproofing.

4. Double layer ventilation.

5. Single layer ventilation.

The ridge serves not only to prevent precipitation from entering the longitudinal hole between the roof slopes, but also to effectively ventilate the space under the roof.

The ventilation of this space is most important in the case of insulated roofing.

The roof ridge ventilation system is manufactured in the following way:

- After the completion of the rafter system, the waterproofing film is fastened across the legs of the rafters, and the upper strips are laid on the lower ones with an overlap of at least 15 centimeters. The seams are glued with a connecting tape.

- Stuffing is carried out along the rafter legs of the counter-lattice, over which the crate is stuffed across.

- On top of the crate, the selected roofing covering is laid, such as ondulin, slate, metal tiles, etc.

The stretched film is designed to protect the elements of the rafter system from condensate accumulating from the inside of the roof covering, as well as from water leaks through the cracks in the covering.

It is clear that such use of the film prevents rotting of wooden elements and the appearance of rust on metal ones.

In the absence of effective ventilation of the space between this film and the roofing, the moisture penetrating there will not dry out quickly, which will accelerate the rotting or rusting of the counter-battens and battens.

The device of a warm roof implies that under the waterproofing layer there is also a layer of insulation.

Since it is most often made of hygroscopic material (for example, basalt or mineral wool), in the absence of effective ventilation, moisture accumulates in it faster, which worsens the heat-shielding properties of the material, and also leads to rotting of the legs of the rafters, between which there are plates of insulating material.

The space for ventilation, which helps to avoid such problems, is equipped as follows: in the lower part of the filing of the cornices, ventilation gaps or grilles are equipped to ensure the flow of air.

In addition, there must be sufficient space between the waterproofing and the roof covering, and a hole must be made between the slopes to release damp air before attaching the ridge to the roof.

In this case, air can exit through the ridge in different ways, depending on the selected roofing material (it may also be necessary to install additional devices for ventilation).

Did the article help you?