In modern construction, many varieties of roofing and finishing materials are used. Profiled sheets, which have long been known in construction, have gained popularity with their excellent performance characteristics and physical and technical properties. This material was originally intended for roofing. Currently, fences are being erected, hangars are being built, the roof is being laid, and the pediment is sheathed from corrugated board. It is about the facing of houses with this building material that I want to talk about in this article.

In modern construction, many varieties of roofing and finishing materials are used. Profiled sheets, which have long been known in construction, have gained popularity with their excellent performance characteristics and physical and technical properties. This material was originally intended for roofing. Currently, fences are being erected, hangars are being built, the roof is being laid, and the pediment is sheathed from corrugated board. It is about the facing of houses with this building material that I want to talk about in this article.

The choice of material for cladding

I would like to say right away that there are no strict requirements for facing a house from corrugated board. This process can be carried out, both with the help of specialists, and completely independently.

When purchasing profiled sheets, you need to pay attention to the marking.

Modern manufacturers offer the following types of corrugated board:

- Bearing corrugated board, which has high strength and is used for interfloor ceilings. These include material marked H, K.

- Roof decking used as roofing and for cladding. These include sheets marked K without polymer coating and with it.

- Wall decking used for cladding the walls of buildings and works on the roof. Such material is marked with the letter C.

- Ceiling profiled sheets used for ceiling cladding in industrial buildings. These include corrugated board marked P.

Advice. For facade work, it is recommended to use wall profiled sheets.

Quantity of corrugated board

The number of profiled sheets is calculated based on the technology of their laying:

- vertical;

- horizontal.

In addition to the main profile, additional elements are used to frame windows, doors, downpipes, plinth and corners of the house.

A correctly calculated quantity and a well-chosen type of profiled sheets will make it possible to complete the framing of a building structure.

Facade finishing

When designing the construction of houses, an important place is occupied by facade cladding.Thanks to the use of corrugated board in this area, it was possible not only to improve the appearance of the building, but also to increase its performance.

The benefits of this finish include:

- Profitability (the relatively inexpensive price of profiled sheets reduces the cost of repair and construction work);

- Resistance to corrosion processes and high strength (corrugated board retains its characteristics in all weather conditions);

- Durability (corrugated sheathing has a high repair period);

- High fireproof properties (this material belongs to the class of non-combustible coatings);

- Lightness (due to their low weight, the sheets do not exert a large load on the ceiling or supports);

- Attractive appearance (a variety of colors allows you to create structures for roofs, facades, fences, walls that are in perfect harmony with the landscape and architectural design);

- Ease of installation (the speed of laying profiled sheets can significantly reduce the time of repair or construction).

Facade cladding technology

Profiled facade is the most common way of cost-effective design of facade elements of administrative, industrial and residential buildings.

The technology of hinged facades is used, providing:

- ease of execution;

- minimum maintenance costs;

- variety of design solutions.

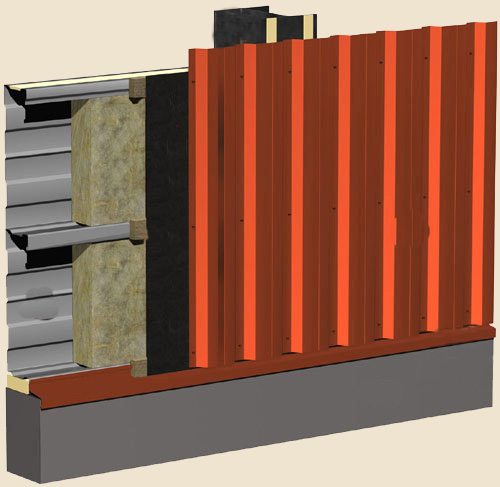

Facade cladding with profiled sheets is carried out in such a way that a ventilated layer is created between the corrugated board and the heat-insulating material, which provides the structure with a long service life.

The principle of installation technology is to ensure air circulation, due to which moisture vapor escapes from under the facing coating to the outside.

This helps prevent mold growth. Decking, as a facade cladding, increases the level of heat and sound insulation.

The installation process for the installation of the facade

Facing the facade consists of several stages:

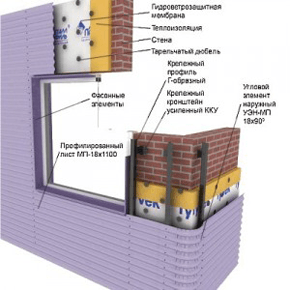

- Fixing the brackets to the wall.

- After mounting the brackets, the slab insulation is laid. The insulation is fastened with dish-shaped polyamide dowels.

- To protect the heat-insulating layer from the effects of moisture and wind, a windproof film is used.

- It is necessary to attach vertical guides having a U-shaped design to the brackets. These elements level the wall, an air gap is created between the guide and the protective film.

- Next, the profiled sheets are fastened. Sheets are laid along the marked lines. After they are fixed, additional elements are installed.

Wall profiled sheets can be arranged in a vertical or horizontal direction, as well as diagonally.

The presence of corner additional elements gives expressiveness to the facade. The light weight of profiled sheets makes it possible to use them on lightweight structures.

Do not miss the fact that the profiled sheets are fastened with galvanized self-tapping screws.

This is done so that moisture does not get under the lining and into the insulation. When moisture gets in, heat-shielding materials lose their properties.

Attention.Another fact that must be strictly observed is that the holes for fastening are drilled with a drill. The use of punches and nails is not recommended.

Laying process for wall cladding

In many cases, the profiled sheet is used to create insulated panels of the wall structure.

It acts as an external or internal cladding. This option is often used when a corrugated board hangar is being mounted.

Facing is carried out in this way:

- Horizontal waterproofing of the foundation of the structure is being carried out. As a rule, roll materials are used for this.

- It is necessary to fix the guide profile to the foundation. The fastening element is an anchor screw.

- Vertical jays are installed in the guide profile. Thus, a wall frame is created.

- A vapor barrier film is mounted on the inside, which is fixed in horizontal layers.

- Next comes the installation of insulation.

- A windproof membrane is installed.

- The corrugated board is fixed with self-tapping screws (with rubber insulation), which are placed in deflections through the wave.

- Corners and drainage are used as framing of openings.

Attention. Rivets are used to fasten the vertical joints of profiled sheets.

Profiled for hangars

Profiled sheets are ideal for the construction of hangars for various purposes due to the fact that they have a high assembly accuracy.

Hangars of any type can be built from this material:

- straight-walled;

- arched;

- tented.

For cladding, sheets with a thickness of 0.5 - 1.2 mm with a polymeric color coating are used. Decking is indispensable if the hangar is being built in a region with increased climatic loads.

This design consists of several elements:

- foundation;

- load-bearing metal frame;

- lining with profiled sheets.

Attention. As a rule, the technology of such construction provides for the presence of a heater in the design.

Gable of the house

When designing the facades of the building, one cannot fail to note the proper sheathing of the gable of the roof, which should be in harmony with the general appearance of the building. More advantageously, the roof gable is decorated with profiled sheets - non-toxic material.

Installation of the material is carried out on a frame made of wooden beams. Sheathing can be carried out at an angle, horizontally or vertically.

In addition to the fact that the corrugated board gives the gable a beautiful look, it provides the roof structure with strength and reliability.

Advice. Fastening sheets must begin on a frame soaked with an antiseptic.

As you can see, the breadth of the scope of corrugated board speaks of the versatility of this material. The main condition in the creation of structures from profiled sheets is the preservation of the quality of its polymer coating during installation work.

Violations of the polymer layer leads to the formation of corrosion, which has unpleasant consequences. Since it reduces the life of the material.

Did the article help you?