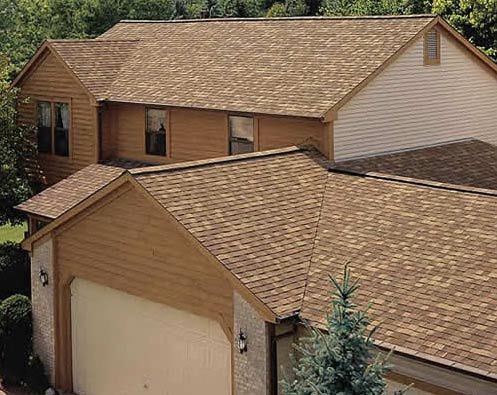

The advantage of natural material for roofing is confirmed by a long history of its use. Oak, spruce, beech, larch, Canadian cedar have found widespread use for roofing.

Different nations call roofing material made of wood differently: shindel, shingle, shingles, shingalas. In this article, we will talk about the characteristics and features of shingle roofing.

Shingles production

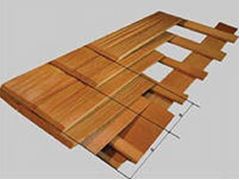

Roof shingles are made of the best quality coniferous wood: oak, Siberian larch, Canadian cedar. This material is mainly made by hand, in the form of wooden plates.

The shingle can be of several types:

- chipped;

- sawn;

- mosaic.

In order for the material to acquire a certain shade, it is impregnated with special means, thereby extending the service life.

Such material is an excellent alternative to modern roofing, especially for the roofs of those objects that are subject to:

- exposure to harsh climate;

- extremely low temperature regimes;

- significant amount of precipitation in the form of snow cover.

Attention. Wood for shingles should be without damage: rot and knots.

The complexity of the forms

Modern methods of production of shingles allow more often in construction to give preference to the option - roofing + shingles. This material is successfully used on roofs with curved shapes and complex configurations..

Depending on the purpose of the object, the shingles fit into 3-5 layers. Multi-layer coating creates on complex rooftops dense and waterproof roofing.

Laying technology

Shingles roofing differs from other coatings not only in properties, but also in laying technology, which is determined by the nature of the material. The shingles are placed on the roof in the same way as scales are laid in a spruce cone.

When exposed to precipitation and high humidity, wooden plates swell a little and increase in size. Due to this, the material closes on the roof.

The roof looks like a bump.In the process of drying, the plates, bending, are raised by a dome, while ensuring the removal of moisture from under house roofs.

Such a natural coating in sunny weather shows its unique properties. If we compare materials such as metal, tiles, then the wooden surface does not transfer heat. This causes coolness in the house during the hot season.

The outer surface of this coating is characterized by a relief structure.

This circumstance protects the roof space from noise resulting from:

- hail;

- rain;

- gusty wind.

Attention. The slope of the slope for laying shingles can be 28-45 degrees.

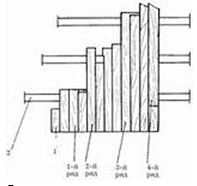

During the construction of residential facilities, shingles are laid in 4-5 layers, utility structures - in 3-4 layers.

The advantage of natural coverage

Wooden plates are able to breathe, so the roof is ventilated naturally. If you create a roof according to the shingle-roof scheme - an additional ventilated gap, then the coating itself and the supporting structures will last much longer.

Basically, shingles, like roofing, has the following advantages:

- ensures long-term tightness of the roof;

- the coating is in complete harmony with the environment;

- lightness of the material (for 1 sq.m. the load is from 14 to 18 kg);

- without a doubt, this is an environmentally friendly coating;

- during installation work, almost waste-free production is observed;

- the coating does not accumulate static voltage;

- condensation does not form under the wooden plates;

- resistance to sudden temperature changes, precipitation and wind loads;

- possibility of use in various climatic conditions, at a temperature from +40 to-70 degrees.

The listed advantages of shingles allow you to create durable and comfortable living in the house with the help of this material.

Roof device

Roof shingles are light in weight. The flooring is carried out on a continuous or rare crate, for the manufacture of which bars 6 cm thick are taken. The distance between the coating in 4 layers and the bars is 25 cm.

A shingle is laid in the direction of the ridge. For the first row of the first and second layers, shortened plates are used. The wooden plates of the first layer are fixed with the lower end to the board, and the upper end to the bar.

The material is fastened with nails 5 cm long so that they pass through the layer that precedes the one that fits.

Advice. In order for the shingle not to be subjected to wind loads, it is necessary to hem the overhang of the cornice with a hemp from the side of the lower surface of the rafter legs.

Mounting Features

The first row of shingles is placed so that the close is located 4 cm from battens from the leeward side. If you install the first row differently, then the eave will begin to dry out prematurely and blacken from the effects of the external environment.

The bars for the crate are hewn in two edges. The device of the crate is carried out from the cornice overhang to the ridge. A board is attached along the overhang, after the lath of the crate. Each plank is fixed at the intersection with the rafter.

Roofing shingles are laid using boards, one of which serves as a guide for laying the base material, and the purpose of the others is to hold the guide.

Auxiliary boards should be at least two. A guide moves along them in the process of laying the shingles.

In places where roofs are lowered, instead of bars, it is recommended to fasten the shingles to a board having a width of 350 mm - for mounting a three-layer coating, 400 mm - for laying a four-layer coating.

For the extreme row, a board with a width of 100-250 mm is used.

Boards for roofing are treated with oil paint in 2 layers and covered with hot bitumen. Thanks to the processing, the board will not absorb water if it flows through the shingles.

In places where the roof slopes, the roofing wears out faster, so the coating layer on the slopes increases by one, compared with the thickness of the main coating. For example, when laying shingles in three layers on the surface of the roof, four must be laid at the place of descent.

The laying of the board on the descent is carried out so that when arranging a three-layer coating, the shingle is located at the same level with respect to the lath of the crate, which is laid above the board. The second row of shingles is attached to this plan. This contributes to the tight adjacency of the rows of shingles to the previously laid layers.

It is highly undesirable to use a groove device on a natural roof. They are longer than slopes, therefore, when they are installed, it is necessary to lay auxiliary lathing strips, every two rows of lathing..

To make the roof waterproof, the ridge and eaves of the roof are laid with shortened plates, and a full-length shingle is used for the main covering. In the first row, at the eaves, the shingles are laid down in the direction of the pile on the surface, in the remaining rows, the pile side is directed upwards.

Attention. Adjacent wooden plates are laid open, the width of the overlap is 40 cm.

Roof shingles require maintenance.

It is as follows:

- snow from the roof is removed with a broom from the ridge of the roof to the overhang;

- the coating is checked for defects.

Working with shingles is quite easy, so it is not surprising that they began to use it not only on roofs, but also as a finishing material for facades and interiors.

Did the article help you?