The market of modern roofing is rich in a variety of high-quality materials, among which a unique roofing material with new architectural possibilities stands out - this is the Cascade metal tile - production is based on an automated method for obtaining a metal profile from raw materials with a smooth surface. The article contains information about the features of the manufacture and installation of this roofing.

The market of modern roofing is rich in a variety of high-quality materials, among which a unique roofing material with new architectural possibilities stands out - this is the Cascade metal tile - production is based on an automated method for obtaining a metal profile from raw materials with a smooth surface. The article contains information about the features of the manufacture and installation of this roofing.

Description of roofing

The cascade metal tile is made of thin, galvanized steel with a multilayer polymer coating and a different color palette.

The shape of this material is close to the classic models of metal roofing, but is distinguished by its clear edges and pronounced decorative grooves.

The relief of a metal tile is similar to the texture of a chocolate bar. This geometry of the material creates a visual effect on the roof, which gives the house individuality.

The presence of grooves on the upper edge of the tile wave not only creates additional decor, but also makes the material resistant to longitudinal loading.

At the same time, the Cascade brand of roofing is the most cost-effective among the entire range of analog materials.

This is determined by an insignificant overlap coefficient when the Cascade metal tile is installed, which produces a minimum amount of waste and the number of joints.

Features of metal tiles

This model of metal tiles has several subspecies: cascade, cascade super or elite.

Each subspecies has minor differences in technical characteristics, but all have the following advantages:

- not subject to combustion;

- resistant to weather conditions;

- prevent corrosion processes;

- ease of installation;

- inherent economy;

- originality of appearance;

- profile stiffness;

- tight fit of additional elements.

Metal tile mp Cascade has the following geometric parameters:

- profile height - 25 mm;

- metal thickness up to 1 mm;

- profiled sheet width from 100 to 150 cm.

These are standard values.

The mounting width and height of the profile may vary depending on the type of metal tile.

Strict geometry, rectilinear shapes and large installation width contribute to easy installation work on roofs with complex architectural forms.

Attention. This type of metal tile is valued not only for its appearance, but also for its high quality due to the technical properties of the material and installation possibilities.

Production technology

Technological lines for the production of roofing material Cascade are constantly being improved, so that the tiles become more durable and reliable, which makes this coating more competitive.

For the manufacture of roofing material automated equipment and galvanized steel with a durable coating are used that do not require painting and treatment with anti-corrosion agents.

The finished metal tile has a wide variety of shades, which increases the design possibilities. Cascade metal tile - installation carried out with ease, since sheets are made of any length.

The mass of such a coating per 1 sq. m is 5 kg.

Complete set of equipment for production

The production line includes a number of technical equipment, which is connected by a single control system.

Basic production includes:

- cantilever decoiler, providing smooth movement of feedstock;

- cutting machine;

- rolling mill - the main unit of equipment;

- stamp - a device for forming a special relief on the surface of the profile;

- guillotine shears;

- receiving device;

- automated control system.

In the production line, the main role is played by the rolling mill, which ensures the formation of a corrugated profile from a smooth steel sheet, which is subsequently stamped to form a pattern on the tiles. .

The quality of the metal tile depends on the quality of the rolling mill and compliance with the technological process:

- accuracy of geometric parameters;

- uniformity of the bending radius;

- clarity of placement and depth of the decorative groove.

In turn, the hydraulic stamping device gives the profiled sheet a natural tile pattern. The control system positions the profile in the stamping device with geometric accuracy, allows you to track the length of the roofing sheet and start the electric motors.

Implementation of installation work

Provides durability, reliability and tightness of the roofing of the Cascade metal tile - installation performed in compliance with the rules, installation technology and taking into account the peculiarities of laying this material.

Regardless of whether you will perform it yourself or entrust the execution to professionals, it is necessary to take into account the following characteristics of Cascade roofing tiles:

- profile for corrugated board has a small overlap coefficient;

- roofing material, which is based on galvanized steel, has sufficient lightness;

- this coating provides excellent longitudinal and transverse stiffness characteristics.

All characteristic properties speak of the economy of this profile. And this, in turn, means that the described coating is convenient for installation.

Attention. When installing a truss system for this material, the step length should not exceed 90 cm. It can be determined by the width of the material used for thermal insulation.The slope for a metal tile roof must be at least 14 degrees.

Features of calculations

Instructions for the installation of metal tiles Cascade will allow you to avoid errors in the calculations and laying of the material. As a rule, when choosing the length of the sheet, you need to proceed from the length of the slope, taking into account the size of the protrusion above the eaves - 4 cm.

You can make a calculation of the material according to the drawing of the roof, but for greater certainty it is necessary to measure the crate. The number of metal sheets is calculated by dividing the length of the cornice by the usable width of the profile.

To carry out installation work with the protrusion of sheets beyond the eaves of the slope, it is necessary to select a length that is a multiple of 30 cm.

Attention. For metal tiles of different types, the useful width is different, for the Cascade material it is 1050 mm.

Styling features

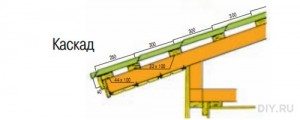

To mount the crate, a board with a size of 32x100 mm is used. The plank that goes to the cornice should be a little thicker (44x100 mm). The laying interval is 300 mm.

The elements of the crate are mounted on the counter-crate. It is recommended to use waterproofing as a lining under the crate, which prevents the occurrence of moisture on the inner surface of the profile.

Also, waterproofing absorbs moisture coming from the side of the insulation.

The end plan must exceed the height of the material profile. For better fixing of the ridge bar, additional rails are used. The cornice strip is fixed until the sheets are fastened.

Cascade roofing is laid from any end. On hipped roof structures, the beginning of installation is the highest point of the slope, from which the sheets are laid evenly in different directions.

When overlapping, the next sheet covers the capillary groove of the previous one.In the metal tile of the described type, the capillary groove is located on the left edge.

It is more convenient to carry out laying from left to right. Laying sheets must be done so that their edges form an exact line. Between themselves, the sheets are fastened with self-tapping screws into the crest of the wave.

When mounting sheets, the accuracy of the tiled pattern is observed. Fastening is carried out with the placement of self-tapping screws in a zigzag pattern. The overlap of sheets in width occurs for each transverse pattern, usually 10 cm is enough for it.

During the roofing works it is worth paying attention to the way of movement on it. For this, soft shoes are put on, the step support is the deflection of the wave of the metal tile.

Advice. For reliable sealing of the roof on hip roof structures on the ridge, sealing tape can be used. Places of overlaps or through exits are treated with silicone mass.

The model - installation of the Cascade metal tile, which we described, is used in new and reconstructed projects. It is amazingly suitable for administrative and individual buildings, distinguishing their roof from other buildings in appearance, and giving it strength and rigidity.

Did the article help you?