Among today's popular roofing materials, a special place is occupied by galvanized roofing corrugated board.

Among today's popular roofing materials, a special place is occupied by galvanized roofing corrugated board.

Due to its performance, aesthetic appearance, environmental friendliness, as well as its moderate cost, corrugated board is a popular material in private construction.

In this article we will tell you about the advantages of corrugated board, as well as about the features of working with this roofing material.

What is corrugated board?

First you need to figure out what is corrugated roofing?

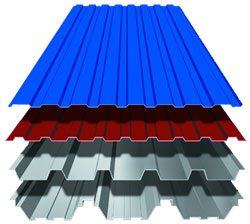

Decking is a metal sheet with a thickness of up to 0.5 to 1.2 mm with a zinc, aluminum-zinc, polymer or combined coating, subjected to cold bending according to a specific profile.

As a result of bending, corrugations are formed on a sheet of corrugated roofing - trapezoidal longitudinal stiffeners, which give the corrugated board strength and stable geometry.

The profile of the stiffening ribs, as well as their height, determine how strong the corrugated roofing will be: the dimensions of the ribs are directly proportional to the strength of the sheet itself. The most common profiling sizes for corrugated roofing models are 10, 20, 45 and 57 mm.

For the arrangement of the roof, corrugated sheets with small ribs are most often used (fortunately, the roofing does not require high load-bearing characteristics), galvanized or coated with a polymer composition.

Both zinc and polymer coatings perform an important function - protecting the metal base of the corrugated board from corrosion when exposed to atmospheric moisture. In addition, it is for roofing corrugated board that the polymer coating performs an important decorative function.

covered with this material do-it-yourself corrugated roof will retain a bright color for a long time, since the polymers used are highly resistant to fading under the influence of ultraviolet radiation.

Advantages of corrugated board

Why is corrugated galvanized roofing so popular?

This is explained primarily by its high performance: mechanical strength, resistance to external influences (precipitation, hail, mechanical stress), resistance to corrosion.

Also, an important role is played by the small specific gravity of corrugated board: for most sizes it is in the range of 5.5 - 9.5 kg / m2 (depending on the thickness of the metal).

Attractive for craftsmen, roofing corrugated board is due to the ease of installation and low cost. So if you are looking for an inexpensive, practical roofing material that you plan to install yourself, then corrugated board is a great option.

Preparing for the installation of corrugated board

The minimum slope angle for the installation of roofing corrugated board is 13-14.

In principle, it is allowed to install a roof made of this material on slopes from 8, however, in this case, it is necessary to pay close attention to roof ventilation, sealing of joints and any openings (including fasteners) - otherwise the risk of leakage increases many times over. .

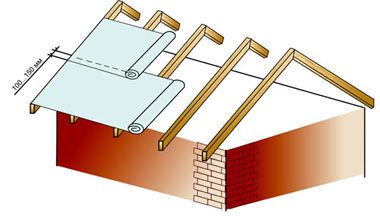

Optimum use of lining under roofing profiled sheet - it is best if it is a superdiffusion membrane. The main purpose of the lining is to prevent condensation in the under-roof space.

We lay the lining in such a way that a ventilation gap of at least 50 mm is formed between it and the first board of the crate in the area of the roof overhang.

The lining is fastened with short nails (25-30 mm) with a wide head. The step of fixing the lining is about 20 - 30 cm, while fixing we start from the roof overhang and gradually move towards the ridge.

On top of the lining on the rafters, we attach a counter-rail - it should prevent damage to the superdiffusion membrane by fasteners.

After all the preparatory work is completed, you can proceed directly to the installation of corrugated sheets on the roof.

Installation of roofing corrugated board

Sheets of roofing corrugated board are necessarily laid with an overlap.

In principle, almost any roofing material is laid with an overlap to ensure tightness - corrugated board is no exception.

As a rule, the side overlap for corrugated roofing is half the wave of the profile, but for shed flat roofs from corrugated board (with a slope of 8 - 12) it is recommended to apply laying with a wider overlap. This installation will ensure that there are no leaks.

The top overlap also depends on the slope angle:

- For roofs with a slope of more than 10 overlap is 100mm

- For roofs with a slope of 10 and less overlap is better to increase to 200-2500 mm.

Also, for sloping roofs, it is justified to use sealing tape or mastic at the joints of corrugated boards. However, the best solution is to use corrugated board, the length of which is equal to or slightly greater than the length of the slope

If we use a sufficiently long corrugated board, a roof devoid of transverse joints has much better waterproofing properties.

We fasten the corrugated board to the crate using special roofing screws 4.8x20 or 4.8x35 mm. Such self-tapping screws have a drill and are equipped with a neoprene gasket. The average consumption of self-tapping screws is about 6 pcs / m2.

Unlike slate, corrugated board is necessarily attached to the bottom of the wave, while the screws should not be overtightened - a damaged gasket has worse waterproofing properties. In the upper part of the wave, the corrugated boards are fixed only in the overlap area.

Note! Ridge elements are attached to the upper part of the wave using self-tapping screws 80 mm long or more.

Galvanized corrugated roofing on the gables is necessarily fixed with the so-called wind bar - a profile designed to protect the corrugated board from excessive wind loads.

Ribs, valleys and junctions of the roof to walls and other surfaces (for example, to chimneys) are covered with corner strips - they protect the roof from moisture penetration.

Roofing corrugated board - galvanized or coated with a polymer - is a wonderful material, working with which is not difficult even for a not very experienced craftsman. So if you have conceived an independent construction of the roof, then corrugated board is the right choice.

Did the article help you?