In this article we will talk about how to make a canopy from corrugated board with your own hands using available materials. The topic that we will consider is of considerable interest, since awnings and visors, if properly made, are a functional decoration of a country house and the adjacent area.

Of course, you can contact specialized organizations and order professional production of these structures. But, unfortunately, the price of this solution will be high, and therefore it will be more correct to carry out the planned work on your own using improvised materials and tools available in the household.

Design features and scope

A canopy covered with corrugated board, unlike polycarbonate products, has a high degree of strength. On the other hand, when choosing such structures for construction in a summer cottage, you need to understand that corrugated board is an order of magnitude heavier than polycarbonate, and therefore the supporting structure must be distinguished by additional resistance to mechanical deformations.

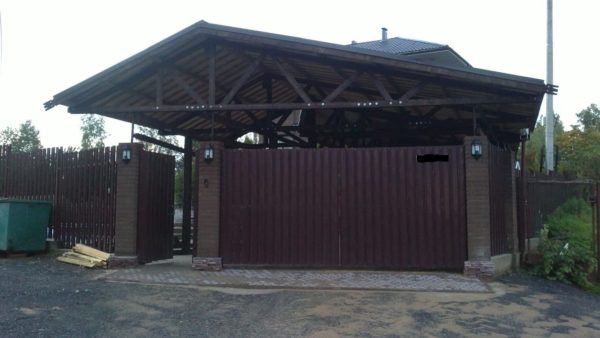

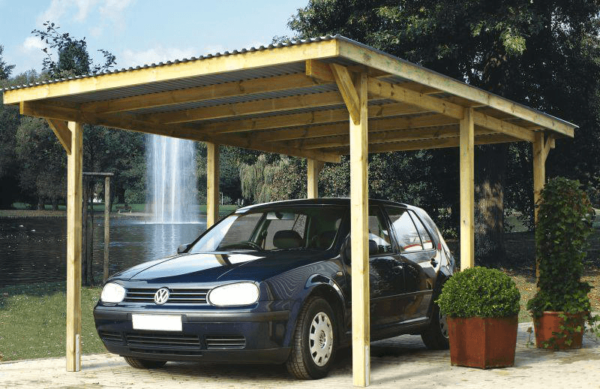

A well-made canopy is a multifunctional structure that can be used as a decoration for a terrace or a recreation area on a personal plot. In addition, such structures are widely used for the construction of a temporary garage or car park.

Structurally, the canopy is a vertical support with a flat single-pitched or double-pitched roofing system. Unlike structures covered with polycarbonate, in this case it is impossible to achieve a curved semicircular shape, since the corrugated metal sheet practically does not bend without crushing.

So, we have considered the features of the application and the design characteristics of canopies covered with profiled sheets, now we will determine how and from what materials they are made.

Choice of building materials

The instruction for assembling a canopy from corrugated board begins with the choice of materials for the manufacture of vertical supports and the upper frame on which the roofing material will be attached.

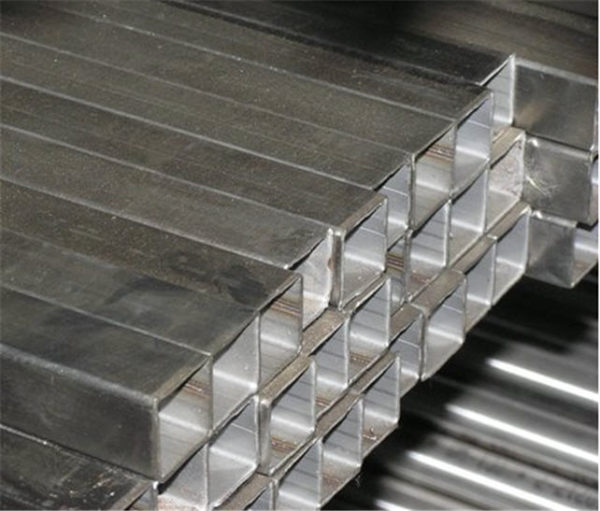

As already mentioned, the structure must be as strong as possible in order to withstand a lot of weight. metal slate. That is why, the best solution for the manufacture of supports and the upper frame will be a profile pipe with a square section and a side of 50 mm.

alternative profile pipe to create a canopy a wooden beam can serve, but in this case the cross-sectional dimensions should be twice as large.

Manufacturing of metal structures

Despite the fact that it is not difficult to make drawings of canopies from corrugated board with your own hands, you can use ready-made projects that have been tested in real conditions.

To work with a profile pipe, in addition to the material itself, you will need a welding machine, a grinder with metal discs, clamps, measuring accessories, a screwdriver with a drill function and self-tapping screws for attaching a profiled sheet to a metal frame.

The manufacturing instructions are nothing complicated:

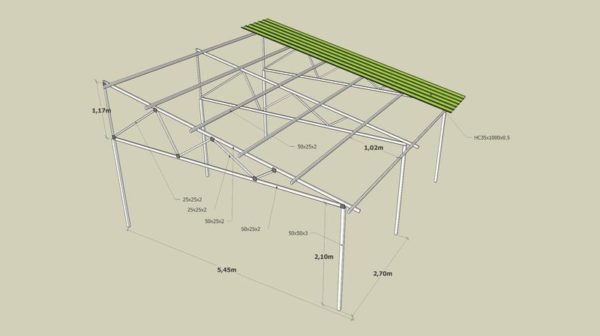

- At the initial stage, we cut 6 vertical supports 2.1 meters long from the pipe.

- Next, we cut 8 beams for the lower trim of the frame and the structure on which the corrugated board will be fixed, 5.4 meters long.

- We cut 2 guides of 6 meters, through which it will be possible to set the slope of the ramp.

- We cut inclined guides, the size of which can be selected in accordance with the proposed drawing or based on our own ideas about what angle of inclination is needed.

- We fix the pre-prepared supports at the proper distance from each other in a vertical position, as shown in the diagram. To ensure proper strength, the supports must be embedded in concrete.

- Next, on the vertical supports, we weld in the required order all the previously prepared elements.

- After the main supporting structure is assembled, we clean the metal surfaces from oxides, prime and paint in several layers.

- After the paintwork has dried, we fix the corrugated board.

Important: Due to the weight of the coating, we do not work alone and use stable stepladders or ladders.

Having laid the coating on the guides, we drill holes of a smaller size in comparison with the diameter of the self-tapping screws. Before screwing in the screws, we apply plumbing silicone around the hole.

In contrast to the installation of polycarbonate, we fasten the profiled sheet without a gap, since in the case of thermal expansion, the sheet steel will not crack.

Production of a supporting wooden structure

The calculation of a corrugated canopy shows that the use of a wooden beam as an alternative to a profile pipe requires an increase in cross-sectional dimensions at least twice.

The use of wood in the assembly of support systems can be caused either by the lack of a welding machine, or by aesthetic considerations. For example, a country cottage can be assembled from a massive beam, and in this case, openwork structures made of steel pipes on a personal plot will not look quite natural.

The instruction for assembling a canopy made of wood, as well as in the case of metal pipes, involves the preparation of parts, namely vertical supports and guides for forming a roofing system.

Planed timber with a section of 100x100 mm can be used as materials for vertical supports.The structure on which the profiled sheet will be strengthened is assembled from a 100x35 mm edged board. The board is placed on the edge and thus the required strength is achieved.

As fasteners, special hardware is used, made in the form of a corner with a certain number of mounting holes. Vertical supports are embedded in concrete.

Important: All blanks, for several days, are impregnated with several layers of bituminous mining.

The part of the beam that will be buried in concrete must be covered with a layer of bituminous mastic.

Upon completion of installation, the finished canopy can be painted with one or another type of paint and varnish materials intended for external work.

Conclusion

Now that we know how and with what materials a corrugated canopy is made, we can put the knowledge we have gained into practice. Are there any questions that need clarification? In this case, we recommend watching the video in this article.

Did the article help you?