In fact, the roof, along with the roofing, acts as a protective barrier of the house from the phenomena that nature presents us with. Therefore, it is necessary to approach the installation of the roof of your own house or industrial building very carefully, taking into account the installation features of all elements of the roofing pie. One of them is a counter-lattice - we will tell you what it is in this article, with a description of important features and common mistakes.

The difference between a counter-lattice and a crate

Many novice builders do not know what counter rails mean and take it for a regular crate. Meanwhile, these two elements of the function in the roofing cake are slightly different, although the presence of one and the other element is important.

Let us give a brief description of these structural elements, so that it is easier to understand their difference.

Let us give a brief description of these structural elements, so that it is easier to understand their difference.

The crate is a row of boards nailed to the truss system, on which the roofing is fixed.

There are two types of crates:

- solid;

- discharged.

In a continuous crate, the gap between the boards is less than 1 cm. Basically, its installation is carried out in two layers:

- the first is discharged;

- the second is solid from moisture-resistant plywood or oriented strand boards, which are laid at an angle of 45 degrees with respect to the first layer.

A solid crate performs the additional function of sound and heat insulation.

Solid device roof battens performed under such types of roofs with a small angle of inclination of the slope:

- soft tiles;

- metal tile;

- flat asbestos slate;

- flat non-asbestos slate.

Discharged cladding for metal roofing has found its application on steel roofs, covered with corrugated sheets, cement-sand or clay tiles.

For the construction of the crate, a beam of 50x50 mm or 60x60 mm is taken. The boards of the batten are nailed to the counter batten. You should take nails, the length of which will be equal to the thickness of two bars.

A counter-lattice (counter beams) is called wooden bars stuffed onto the rafters, directly onto the hydro-barrier material.

Counter bars are mounted to provide a ventilation layer of waterproofing, which can be roofing felt or hydro-barrier membranes, films.

main function counter battens for metal roofing - creation of a ventilation channel between the waterproofing layer, the crate and the roofing.

During operation of the roof, condensation may form on the inside of the coating. The accumulation of condensate drops can lead to rotting of the roof structure.

The counter beams, in addition to being a frame for the boards of the crate, provide an influx of air necessary to remove moisture.

For the manufacture of counter bars, blanks with a section of 30x50 mm are taken. On roofs that have a complex structural shape and long rafter legs, blanks for 50x50 mm counter beams are taken.

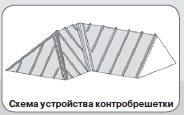

Installation of the counter-lattice

The installation of a counter-lattice is recommended for all types of pitched roofs. We have already said that counter beams are nailed directly onto the waterproofing material along the rafters.

This allows you to raise the lathing structure to the height of the bar and provide effective ventilation of the roof space.

As a rule, the height of the counter-lattice can be 2-5 cm. On simple roofs, 30x50 mm bars are used. On complex multi-pitched roofs, the thickness of the counter bars should be increased to 50 mm.

Installation of the counter-lattice begins after the waterproofing material has been laid on top of the rafters. Previously, it was customary to use roofing material as its quality.

Now many manufacturers offer high-quality and reliable waterproofing films or membranes.

The waterproofing is fixed to the rafters, then the counter-lattice is stuffed.

Check out some important points on arranging counter bars:

- Counter bars 30x50 mm thick and 135 cm long are fixed to the rafters in 300 mm increments using galvanized nails;

- If it becomes necessary to move along the counter-lattice during the installation of waterproofing, then it is necessary to build a rough crate;

- On roofs with a slope of 30 degrees, counter bars with a section of 25x50 mm can be used. When creating a counter-lattice on roofs with a smaller slope, you should not save on material.

It is worth paying attention to how the counter rails (bars) are equipped in the area of \u200b\u200bskates and valleys:

- For the installation of skates, it is necessary that the upper planes of the faces of the counter bars intersect at one point. To do this, the bars of opposite slopes are sawn at the required angle. Properly mounted on the ridge, the crate contributes to the accuracy of calculating the step of the crate boards and laying, for example, the top row of tile elements;

- Near the valleys, the main counter-bars are nailed in 10 cm increments to the longitudinal bars of the ridge or valley. This contributes to the free removal of dust, condensate, snow, as well as effective ventilation of the roofing.

It is necessary to pay attention to the common errors in the device of the counter-lattice under the valleys, when, during installation, the beams are laid tightly to the flooring of the valley.

Maintaining a distance of 5 to 10 cm between the bars and the valley support will ensure free flow of water. In the case of a tight fit, the ventilation of the valleys deteriorates, and the removal of condensate through the cornice overhang is difficult.

In addition, construction debris will accumulate in the valley during installation. And the ends of the counter bars are damaged by moisture.

When arranging gentle valleys under the counter-lattice, a sealing tape is used, which is justified and justified in terms of eliminating leaks.

Attention. If these recommendations are violated, the design of the valleys and the ridge may be violated.

It should be borne in mind that the counter rails are attached directly to the waterproofing material with nails. Up to 10 fasteners are used per 1 sq.m of surface.

In this case, the waterproofing material at 10 points has leaks that are vulnerable to moisture penetration, especially during prolonged rain.

Such phenomena often occur when roofers do not mount the crate and roofing on a rhinestone along the counter-lattice.

Attention. Moisture leaks through the attachment points of the counter-bars with waterproofing are temporary. From the moment of laying the roofing material, they are eliminated. Moisture that has entered the roof structure is removed due to the arrangement of a ventilated space.

Material for counter battens

As with any installation and construction work, the construction of a counter-lattice begins with the selection of raw materials for it.

If it is planned to equip a roof with a large coating weight, then it is necessary to use pine or oak as a raw material for counter beams. For a lighter covering, for example, flexible tiles, soft wood is used.

We equip the counter-lattice under natural tiles

When arranging a roof with natural tiles, the counter rails used for attaching waterproofing should have different thicknesses:

- the lower bars carry a large load, so they must be of great thickness;

- middle slats - a little thinner;

- the top bars are the thinnest.

Such a design with a crate mounted on top of it will provide the roof with reliability.

And to give maximum structural strength, it is better to use stainless nails. A professionally installed counter crate can last several decades.

Warm roof

When installing a warm roof, it is very important that ventilation under the roofing is properly organized. As a rule, a vapor barrier is laid on the insulation from the inside of the room, and waterproofing from the side of the roof.

There must be a ventilated gap between the coating and the waterproofing to ensure the performance of the functions of the insulation layer placed under the waterproofing material. As we already know, such a gap is provided by rails mounted under the counter-lattice.

The counter bars under the warm roof have a section of 40x50mm or 50x50mm, they are laid on the rafters, fixing the waterproofing layer. For fastening it is better to use self-tapping screws, 90 mm long.

Attention. It is not necessary to use a solid beam for the counter-lattice. It can be assembled from composite elements.

Counter bars for finishing

Many may imagine that such a concept as counter rails (beams, lathing) is applicable only to the roofing device. Although counter beams and lathing are often used when finishing facades.

Due to the use of such a design in the decoration, the ability of materials to ventilate increases.

The situation is such that now rarely anyone mounts a counter-lattice. There are strong arguments in favor of its use:

- due to the bars between the waterproofing and finishing material, a distance is formed;

- when moisture gets on the waterproofing layer due to this distance, it does not enter the finishing elements;

- this increases the service life of the finish, especially if wood (block house) was used as it.

As you can see, the importance of the counter-lattice, both on the roof and on the facade, is equally significant. Therefore, its use as part of a roofing cake determines the quality of the roofing and the life of the roof as a whole.

Professional roofers recommend that developers lay a counter-lattice on sloped roofs under the crate to avoid condensation and protect the roof structure from damage.

Did the article help you?