Every homeowner strives to improve the backyard. A light roof over a dedicated area will allow you to relax in the fresh air in any weather. Too much protection from precipitation will clutter up the territory, so the construction of polycarbonate canopies today is a relevant and popular option.

Benefits of a light canopy

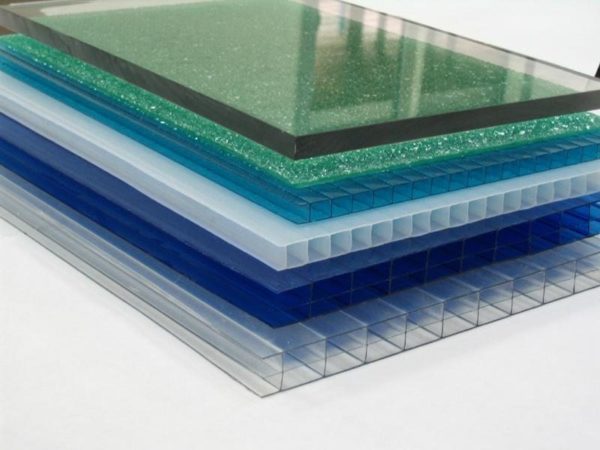

Sufficiently new material has already been appreciated not only by summer residents. Initially, it was used for the construction of greenhouses.Unlike fragile glass or fragile film, which had to be changed annually in greenhouses, honeycomb coating lasts more than one season. Therefore, the canopy from it does not have to be patched after every whim of the weather.

- It fits perfectly even in the smallest area, does not interfere and does not constrain. The structure looks light and airy, thanks to the transparency of the roof.

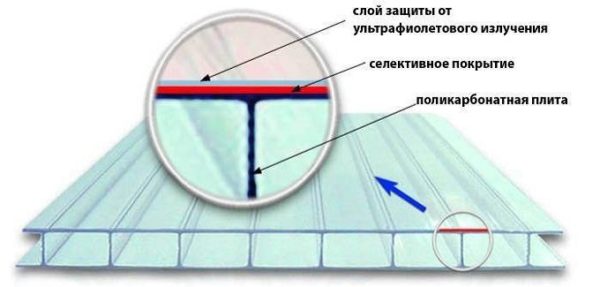

Note! The polycarbonate coating creates a soft diffused light in both sunny and cloudy weather. Plants growing around will not be shaded. The roof is able to retain ultraviolet rays, which is also important.

- Investments in materials are minimal, and building a canopy with your own hands is not difficult.

- With high-quality installation, the structure will last without repair for 10 years or more..

- Cellular polycarbonate is very easy to transport and install, besides, it does not create loads on the frame.

- If desired, the canopy can be quickly dismantled or moved to another location..

- A tastefully executed structure will decorate the landscape of the backyard territory.

- Under the roof you can put a car, do repair work, relax, train.

- Those who like to cook on the grill or gather for barbecue will appreciate the roof over their heads. Your children will now be able to play outdoors even in the rain, breathing ozone.

- Gives a design idea a reality. You can choose the desired color of the coating, and the structure of the material will allow you to design almost any shape.

Features and properties of polycarbonate

- Sheets tend to bend well, cut into fragments of the desired size extremely easily. This is especially important if we are building a canopy with our own hands. You can do without expensive tools, a sharp enough knife and tape measure.

- The honeycomb-type stiffeners, consisting of several layers with a gap between them, give the material increased strength without adding extra weight. Rainwater flows well along the grooves, and snow slides off without accumulating on the roof.

- Plastic is resistant to moisture, does not rot and does not rust, is not afraid of sunlight. Withstands even strong wind loads. Thanks to its flexibility, it does not break under a layer of snow.

- Fastened to the frame with self-tapping screws with a waterproof washer. It is both simple and reliable, water will not seep under the roof.

- Manufacturers offer material in various colors. Without losing transparency, it is able to create any atmosphere, give the desired style to the space. Under the canopy, you can make soft green or blue lighting, or pre-sunset cherry, or maybe sunny yellow.

Construction planning

Depending on how the polycarbonate canopy is planned, as well as its size and purpose, the appropriate material is selected.

Material calculation

- The thinnest monolithic sheets have a thickness of 4 mm. They are good for arranging greenhouses and greenhouses, but you should not buy too thin plastic for a canopy, even despite its cheapness.

- For a medium-sized street structure, panels with a thickness of 6 mm to 8 mm are optimal.

- A reinforced visor or roof will be made of 10 mm polycarbonate. They can sheathe not only horizontal, but also vertical planes.

- The maximum thickness of the panels is 16 mm, which is already a serious protection even for a large-scale canopy. But the price in this case will be higher than for thinner counterparts.

Note! Monolithic sheets of standard (1200 × 210 cm) sizes are produced. But when buying, you can ask the seller to cut the sheet into the dimensions you need. You can also be offered cuts of different formats, which is also convenient.

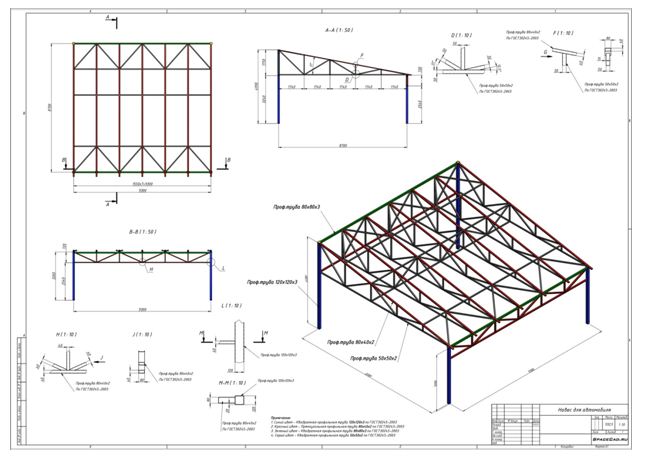

Create a canopy project

Before you go to the hardware store, decide not only on the type, but also on the amount of material. This is possible only after creating a simple drawing with the dimensions of the structure.

- If you have already chosen a place for a future canopy, measure the perimeter of the site. It is desirable that it be slightly larger than the planned structure.

- The most popular are the arched type and the roof with one or two slopes.

- Shed roofing is good if the canopy is attached to the wall of the house. The remaining varieties are suitable for a separate structure.

- As a material for the frame, both a wooden bar and metal pipes are suitable. But do not forget that for the installation of metal you will need a welding machine.

- For a small canopy, the instruction allows you to build four racks in the corners. But a more powerful building will require reinforced supports in larger quantities.

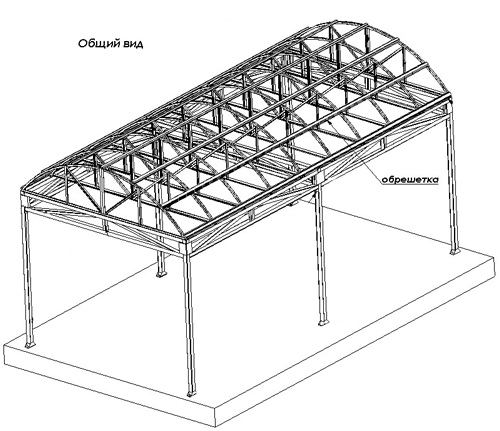

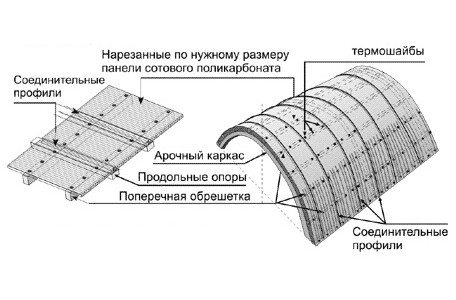

- Keep in mind that the arched type has its own characteristics. The frame is supplied with semicircular trusses, which stiffen the roofing.

Note! it is convenient to use aluminum profiles for the manufacture of the frame. They do not rust, are easily cut, fastened with self-tapping screws or bolts. This means that costly welding and time-consuming installation can be avoided.

Building construction

Experts, for whom the installation of canopies with their own hands is a familiar and mundane thing, recommend that the average homeowner not build an overly complex system.

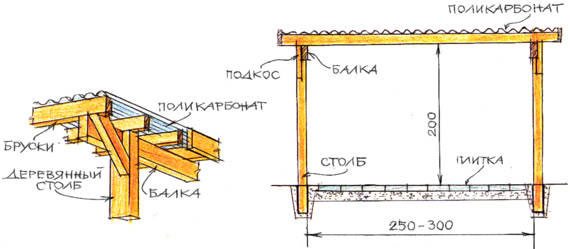

For the manufacture of semicircular supporting trusses, you will have to master the pipe bending machine. Fitting the arcs to each other is also a rather complicated process. The simplest option is a shed roof. It is easy to build and requires almost no maintenance.

- The site is cleared of debris and foreign objects and leveled.

- Places for future racks are marked. Do not make the distance between them more than 2/3 meters. Too large a step will negatively affect the strength of the base.

- The height of the canopy is made based on the growth of the owners with a margin. It turns out at least 2.5 meters. A very high ceiling is undesirable, as gusts of wind will quickly loosen the building.

- Racks are dug into prepared pits with a depth of 70 cm or more. Then they are poured with concrete, leveling vertically until it hardens.

- If a wooden beam is used, to prevent rotting, the driven-in ends should be coated with bitumen and wrapped with polyethylene.

- After the concrete has completely hardened, you can proceed to the arrangement of the upper trim of the system.

Note! to simplify the task, prefabricated canopies are made with opposite pairs of racks of different heights. The difference forms the angle of inclination of the roof slope. The pavement is then laid from the two higher supports sloping down to the two lower ones.

- Rafters are fixed to the finished perimeter. The more often the step between them, the less likely the polycarbonate sheets are to sag.

- It is convenient to fasten the bars with aluminum corners and plates, planting them on self-tapping screws.

- After the frame is ready, all wooden parts should be covered with an antiseptic. The tree will not rot from moisture and will last for decades. Finishing coat - waterproof varnish or paint.

- Now you can equip the roof. Polycarbonate sheets are cut with a sharp knife, pasting the cuts with perforated adhesive tape. This will prevent water from entering the profile.

- Connect the sheets with a plastic docking profile. The lock is attached to the frame, then sheets are laid end-to-end on it and the cover of the device is snapped into place.

- The floor under the roof is concreted, it can be tiled. It does not hurt to make a drainage groove around the perimeter, then the site will remain dry under any conditions.

Conclusion

Improving your outdoor seating is easy. A minimum of materials and energy spent, and now your site is equipped with additional amenities.

The video in this article offers you additional information.

Did the article help you?