Today, in almost every area you can find a canopy of one design or another. From the most simple and inexpensive, to capital and carefully thought out. The material for their construction is varied, but more and more often they began to build light buildings with a polycarbonate roof.

Advantages of polymer coating

Manufacturers are developing more and more convenient and affordable materials at an enviable rate.Before the owners of greenhouses had time to appreciate polycarbonate, it immediately attracted the household craftsmen, who hurried to use the polymer for a lot of useful things.

- The coating is so light and supple that the structures of polycarbonate canopies are almost weightless and airy.

- The finished roof does not obscure the site at all, does not clutter up the space and does not strain in all respects.

- Due to the flexibility of the sheets, you can create designs of any, the most unexpected shapes. Smooth or broken lines are achieved with equal ease.

- If desired, you can purchase a material that has a certain color with translucency. The light transmission capacity is not lost, but the lighting inside the space changes. Blue, green, pink or yellow - to the taste of the customer.

- Polycarbonate is extremely easy not only to transport and store. Installation of a canopy made of polycarbonate is within the power of even an amateur in building intricacies.

- Snow, leaves and rain water will not linger on the surface.

- Design features give the polymer excellent heat and sound insulation properties.

- The roof will never rot or rust, it does not need to be painted or coated with protective compounds.

- If necessary, fragments are dismantled and transferred to another place without loss of positive qualities.

- With proper installation and operation, polycarbonate will last at least 10 years.

How to choose the right material

Many are concerned about the question - how not to get lost in a rich assortment and choose the best option.The fact is that the thickness of the polycarbonate for the canopy plays a decisive role.

Note! Those who want to save money will be disappointed, having bought the cheapest and thinnest polymer, the owner will very soon be forced to replace it with a new one. If the color depends only on the taste of the buyer, then the quality is directly proportional to the thickness of the sheets.

Choice of thickness

- The minimum thickness of a monolithic analogue is 4 mm. For a greenhouse, this polycarbonate is good, but it is of little use for a canopy. If you did buy it, don't be surprised if the roof has to be completely replaced in a year or two.

- 6mm polycarbonate canopy material will last longer. But it is better suited for structures with a small area, or for visors.

- large canopy (for car parking, parties, etc.) it is desirable to cover with sheets of 6 mm and above. It can withstand strong enough wind, does not bend from the snow.

Note! You can choose not only a monolithic type of polycarbonate, but also a cellular one. If in the second case the sheet has two layers connected by many edges, then in the first case there are no cavities at all. A monolithic sheet has a lower

price .

Accounting for wind direction and bending

In many regions, strong winds are a fairly frequent visitor. Therefore, before erecting the frame and before covering the canopy with polycarbonate, two main factors should be taken into account.

- The air channels in the sheets run along the grooves. By installing them parallel to the most frequent wind direction, you will significantly reduce the likelihood of roof damage.

- With an arched type of roof, the sheets will have to be bent. For a material of a certain thickness, there is a corresponding instruction indicating the allowable angle.When buying, be sure to study the recommended parameters and stick to them.

Note! Bending polycarbonate is allowed only across the direction of the channels. The packaging will also indicate which side of the plates is coated with UV protection. It should be laid with a protective layer up.

Which frame is better

Since polycarbonate is light in weight, the load on the base is expected to be minimal. But this is not a reason for mounting an unreliable and shaky frame.

Savings will be costly - the entire system will collapse at the first strong wind or thunderstorm. Therefore, it is most effective to find a "golden mean" by mounting a canopy that fits into the overall style of the site.

- A wooden beam is convenient in almost every respect. The availability of material and ease of processing, presentable appearance captivate. The more practical the tree is if you are used to doing everything with your own hands, making do with a minimum of tools. Polycarbonate in this case is fastened with self-tapping screws, sheets are joined with special plastic locks.

- All surfaces, especially underground parts, must be treated with a composition that prevents decay. Additionally, it is recommended to cover the base with waterproof varnish or paint.

- Steel pipes and profile. Here you have to get a welding machine and a grinder. But that's not all, if you have planned an arched structure, the arcs for the polycarbonate canopy must be bent. And not by hand, but on a pipe bending machine, perfectly fitting the dimensions. If you are not afraid of these little things, you can safely take on the job.

- Aluminum pipes and profile.The material is malleable, welding is not needed here, enough connecting corners and plates, self-tapping screws and bolts with nuts. Light weight and corrosion resistance add to the pluses.

- Combined option. Here you can combine several different materials. For example, the racks are made of iron pipes, and the strapping and rafters are made of wood. This is beneficial if you have various trimmings left over from repairs or construction.

Carport Installation

Since the car has a considerable weight, the area for its parking is concreted before the polycarbonate is fixed to the canopy. The perimeter is made with a margin so that it is possible to walk and drive in without damage to the car.

- The selected place is cleaned and leveled.

- A formwork about 25 cm high is mounted around the perimeter.

- Sand is poured in an even layer, then gravel, leveled and rammed.

- A reinforcing layer is desirable, the mesh is applied to the gravel before pouring.

- If a permanent canopy is planned, support racks are immediately installed.

- For a temporary structure, it is better to lay short corner posts. The main supports are then screwed to them, which, if necessary, can be easily screwed.

- After checking the racks for a strict vertical arrangement, a concrete solution is poured, forming a slight slope for rainwater to drain.

- When the solution hardens, mount the top harness and truss system.

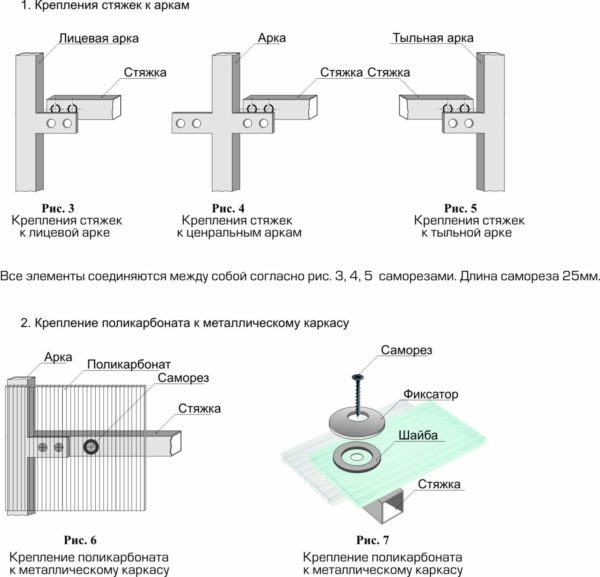

- Lastly, they equip the roof, fixing the sheets to each other (latches) and to the base (self-tapping screws).

Conclusion

It is quite possible to build both a small and a capital canopy on your own.Spend a weekend for future comfort, and a positive result will delight you and your household for a long time to come.

Our video in this article will reveal the secrets of building canopies.

Did the article help you?