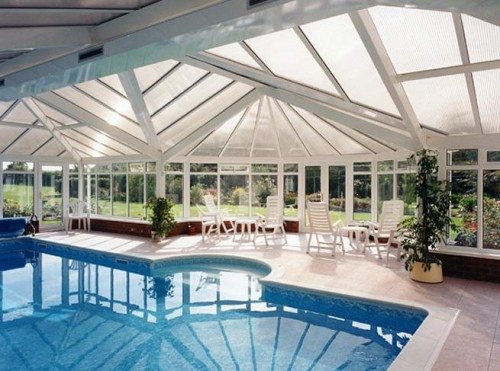

So, your house is built almost completely, and it's time to start arranging the roof. And if you want the roof of your house to become a kind of masterpiece, then a transparent roof is a good solution. Roofs made of transparent materials, be it glass or polymers, will be a wonderful decoration for your veranda, greenhouse or living room. Also, such roofs are widely used in external architecture - gazebos, canopies over the porch and paths, roofs of summer houses look very good.

So, your house is built almost completely, and it's time to start arranging the roof. And if you want the roof of your house to become a kind of masterpiece, then a transparent roof is a good solution. Roofs made of transparent materials, be it glass or polymers, will be a wonderful decoration for your veranda, greenhouse or living room. Also, such roofs are widely used in external architecture - gazebos, canopies over the porch and paths, roofs of summer houses look very good.

Naturally, in order to put all this splendor into practice, you will have to work hard, and very seriously. Alas, the technology described in jokes “cover the roof with plywood and paint it in a transparent color” does not work!

Materials for a transparent roof

Modern transparent roofs can be made from a variety of materials, and below we will look at the most popular ones.

Most often for the construction gable transparent roof plexiglass is used - a material that is close to glass in its optical characteristics, and in structure to a polymeric material.

However, if you take a closer look, it turns out that a variety of materials can be hidden under the name "plexiglass": transparent polyvinyl chloride and polystyrene, acrylic glass and transparent polycarbonate.

It is the last two materials that will be considered in more detail - after all, most likely, we will use them to build a transparent roof.

- Acrylic glass (polymethylacrylate, plexiglass) is exactly the material that is most often called plexiglass. This material is characterized by high light transmission, it is sufficiently strong, resilient and resistant to mechanical damage. Acrylic glass has a specific gravity that is half that of traditional silicate glass. Acrylic glass is used for glazing greenhouses, greenhouses, arched coverings, vaults, and so on.

Acrylic glass is produced in sheets with a thickness of 1 to 25 mm. You can find both smooth and corrugated acrylic glass for decorative glazing, as well as body-tinted acrylic glass (with greenish, bronze, silver and other shades).

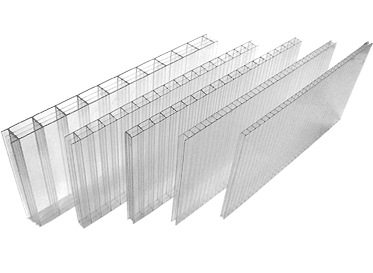

- Polycrabonate is one of the best solutions for creating a transparent roof.Strong, resilient, and virtually unbreakable, this roof plastic has an impact strength that is 150 to 200 times that of silicate glass. Cellular polycarbonate (a kind of sheet industrial polycarbonate) in terms of its thermal insulation characteristics is practically not inferior to double-glazed windows installed in metal-plastic and aluminum windows. And it is suitable for such a design as mansard roof.

Polycarbonate roofs are safe, retain heat well and do not transmit ultraviolet light, which is also an important advantage of this material. A house with a transparent polycarbonate roof looks just as presentable as with a glass one - and building such a roof is incomparably easier.

Note! There is an opinion that the use of polycarbonate panels for glazing greenhouses and conservatories adversely affects the development of plants, since polycarbonate does not transmit ultraviolet rays. In fact, the main role in the life of plants is played not by ultraviolet, but by light rays from the visible part of the spectrum. So if your plants are getting enough light, then you don't have to worry about UV. The same, by the way, also applies to metal-plastic windows with energy-saving double-glazed windows.

However, polymeric materials for creating a transparent roof also have a number of disadvantages. They are subject to abrasive damage and are much easier to scratch than glass.

Also, these materials are characterized by a significant coefficient of thermal expansion, and this must also be taken into account when arranging the roof - otherwise the polycarbonate sheet that has expanded under the influence of heat will deform or crack.

Roof glazing with metal-plastic or aluminum

In addition to polymeric materials, modern double-glazed windows are actively used for arranging a transparent roof. In some cases (when the configuration of the glazed opening in the roof allows it), metal-plastic structures, or structures made of the so-called facade aluminum, can be used.

However, when choosing a profile system, it is necessary to pay attention to whether it is intended for such a structure as a mansard roof with its own - i.e. whether the drainage drainage system of the profile will work effectively when the structure is installed at an angle (or even horizontally).

First of all, this applies, of course, to opening structures - with the deaf, the situation is much simpler. And yet, even if there are no opening parts in your transparent roof, the issue of sealing the connecting nodes is very acute.

Note! For safety reasons, for roof glazing in this way, we recommend using safety glazing - for example, glass armored with a special film or triplex.

However, roof glazing using a metal-plastic or aluminum profile is a task that is hardly up to a non-professional. So if you decide to choose this option, then you will have to contact specialized companies.

Another thing is transparent plastic for the roof (be it acrylic glass or polycarbonate). You can easily handle these materials on your own. Especially if you approach the work on arranging the roof responsibly and with the proper level of theoretical training.

Self-arrangement of a roof made of cellular polycarbonate

We will consider one of the most popular options for a transparent roof - a roof made of cellular polycarbonate.

If you have never worked with this material, then before you start building large roof structures - for example, the roof of a greenhouse or a round "lantern" in the living room ceiling - it is better to try simpler roof patterns.

For example, make a roof over the porch or cover the gazebo with polycarbonate. So you will acquire the necessary skills to work with the material - and any difficult work will be up to you.

The technology for making a roof made of cellular transparent (or translucent - if you prefer a tinted roof) polycarbonate is as follows:

- Work on roofing with polycarbonate begins with the creation of load-bearing structures. The stiffer and stronger the roof frame is made, the more reliable our roof will be. And at the same time, we must remember that we are making a transparent roof, which means that there is no place for too thick load-bearing beams. It is optimal if 60x40 or 60x80 mm rafters are used for the frame.

- We fix the rafters in such a way that the distance between their central axes is 1.01 m (this figure is due to the width of the polycarbonate sheet)

Note! When installing a transparent roof truss system, it should be remembered that for a transparent polycarbonate roof, the minimum allowable slope angle is 5 (for ease of calculation, you can take 9 cm per 1 m of the structure in length). The optimal angle that provides the required drainage is 10 and more.

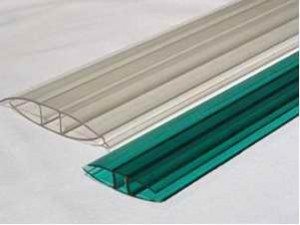

- We attach connecting and end profiles to the rafters. You can buy them in the same place as polycarbonate - while the size of the profile must correspond to the thickness and dimensions of the polycarbonate plates.

- We fix the limiters of the plates at a distance of 20 mm from the edge of the profile.

After the supporting structure is ready, we proceed to laying the polycarbonate:

- We stick adhesive tape on the side surfaces of the polycarbonate plates - this will protect them from exposure to reflected sunlight.

- We also glue a strip of adhesive tape on the upper face of the polycarbonate sheet, and perforated adhesive tape on the lower face. This will prevent dust, debris and insects from entering the chambers.

- If we use polycarbonate panels for the roof, treated with a compound that protects against ultraviolet radiation, we lay them in such a way that the marking is on top.

- We fix the plates in the grooves of the profiles, paying attention to the gap between the edge of the polycarbonate plate and the edge of the profile. This gap must be at least 5 mm - so it can compensate for thermal expansion, which is very significant even for transparent polycarbonate panels.

- We fix the plates with profile fasteners and remove the protective film from the plates. We install plugs.

If we did everything correctly, then the connections between the transparent polycarbonate plates do not require additional sealing. Additionally, only the joint of the roof with the supporting structures should be treated with silicone sealant or waterproofing mastic.

transparent roof maintenance

Before you make a transparent polycarbonate roof, consider how the roof will be maintained. The thing is that a roof made of transparent materials looks presentable and provides lighting only when it is perfectly clean.

Therefore, the cleaning of debris, branches and leaves, dust and stains from rainwater must be done regularly - otherwise the roof will look sloppy.

And yet, despite all the difficulties in the construction and the expensive cost, a transparent roof can be an excellent decoration for your house, summer house or gazebo.

Did the article help you?