The roof is an important structural element of any house, designed to protect the interior from various atmospheric influences. Consider what traditional and new types of roofing are used in construction today.

The roof is an important structural element of any house, designed to protect the interior from various atmospheric influences. Consider what traditional and new types of roofing are used in construction today.

Before proceeding to an overview of the roofing materials used and roof structures, it is worth explaining what builders call a roof.

There is a fairly clear definition - the roof is the upper enclosing structure of any building. The composition of the roof includes:

- Carrying part. These are rafters, girders and other elements that are used to transfer the load created by the own weight of the roofing, as well as snow and wind, to the supporting elements and walls of the building.

- Outer shell.This is the top covering of the roof, which protects the inner layers from getting wet and exposed to wind.

Roof structure

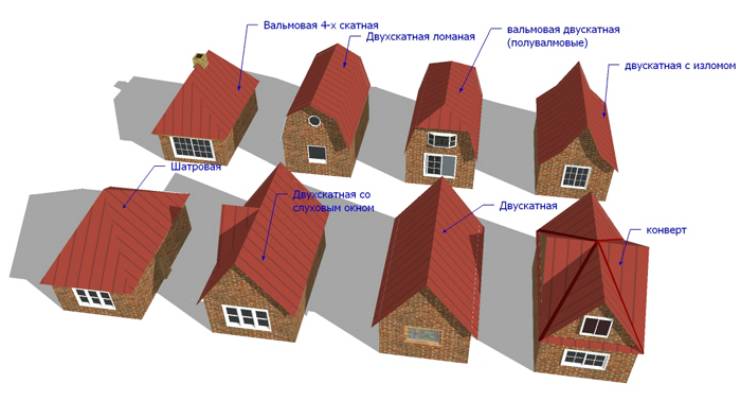

According to the design of the roof can be divided into two large groups:

- Attic;

- Atticless.

The first version of the roof can be made with or without insulation. During the construction of a cold (non-insulated) roof, the thermal insulation of the upper floors is achieved by insulating the floors.

In addition, the roofs are divided according to the constructive type into flat and pitched.

The latter, in turn, are divided into the following varieties:

- Shed. In this case, the supporting structure of the roof rests on opposite walls of the building, which have different heights.

- Gable. This is a classic option for small residential buildings. Such a roof may have a uniform or uneven pitched angle and differ in the size of the overhangs.

- Hip. This roof has four slopes. Moreover, two of them are made in the form of a trapezoid, and two - in the form of a triangle.

- Another variant of a hipped roof is a hipped roof. In this case, all slopes are reduced to one upper point and are made in the form of an isosceles triangle. This type of roofing is used on buildings with a square plan.

- Multi-forceps. A roof with a large number of ribs and valleys (external and internal corners). This option is used on houses with a plan in the form of a complex polygon.

- Attic. This version of the roof is used where the attic is planned to be used as a residential floor.

- Domed and conical roofs are used on buildings with a plan in the shape of a circle.

Supporting structures of the roof

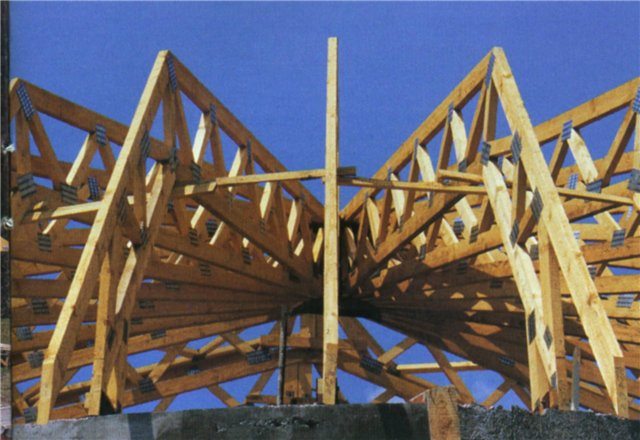

Despite the fact that there are different types of roofs, a triangle is the basis of any truss system, as this is the most economical and rigid structure.

The triangular shape is created by rafter legs (upper belt) and puffs (lower belt). The upper part of the rafter legs converges in the ridge of the roof, and the lower belt is attached to the walls of the house.

The composition of the "roofing cake"

In order to reliably protect the house from bad weather, one roof covering laid on the supporting structures is not enough. To increase the protective properties, a multi-layered “pie” is created, in which each of the layers plays a specific role. Consider how the roof is arranged.

As a rule, the composition of the roofing pie includes:

- Top (covering) roofing material.

- waterproofing layer;

- insulation;

- Vapor barrier.

What influences the choice of roofing material?

As a rule, most difficulties arise when choosing a covering roofing material. When constructing a structure such as a roof, the types of material should be selected taking into account several important factors.

Among them:

- architectural solution. When choosing a material, it is necessary to take into account the shape and design of the roofing system, as well as the appearance of the future building.

- It is also necessary to take into account such a parameter as the collection of loads on the roof. It should be remembered that the supporting structures must be able to withstand not only the weight of the roofing cake, but also the weight of the snow cover, and the wind load characteristic of the region where the construction is being carried out.

What warranty periods do manufacturers set for different types of roofing?

- Soft tiles - 15-20 years. Moreover, the guarantee is given specifically for the tightness of the coating, but for the preservation of its color.

- Metal tile - 5-25 years. The warranty period depends on the quality characteristics of the steel used to make the roofing material.

- Natural tiles - 20-30 years. The warranty may be void if the conditions of transportation have been violated.

- Slate -10 years;

- Wavy bituminous sheet material (such as ondulin) - 15 years;

- Roofing steel and corrugated board - 15-20 years;

- Slate roof - 30-40 years

- Seam roof - 15-20 years;

- Copper roofing - 40-50 years.

Advice! The warranty period for the coating and the life of the roofing material are far from the same thing. As a rule, the service life is two times longer than the warranty period for the material.

Types of roofing material

With all the variety of material choices, the following types of roofing can be distinguished:

- Roll;

- Bulk or mastic;

- Film or membrane;

- Leafy;

- Piece.

Consider these types of materials and the features of their installation.

Roll roofs. To create them, polymer, polymer-bitumen and bitumen materials with a reinforcing base (fiberglass, polyester, cardboard) are used.

Such materials are usually used on flat roofs. For roof installation a continuous crate is built from plywood, flat slate or similar materials. When performing repairs, new material may be laid directly on the worn pavement, which must be cleared of debris.

The roll material is fastened by fusing.The master warms up the base and the lower part of the rolled material, after melting the bitumen, the material is rolled out and rolled with a roller for better adhesion.

Advice! This work is more convenient to do together. One works with a burner, the second one rolls out the material and rolls it with a roller.

Self-leveling or mastic roofing. This option is convenient for flat roofs that have a solid base. A composition consisting of one or two components is applied to the prepared base and leveled.

After curing, the coating becomes completely sealed, elastic and strong enough.

Installation work begins with the preparation of the base, it must be dry and thoroughly cleaned.

At the first stage, the reinforcing material is rolled out (usually fiberglass), then the mastic prepared according to the instructions given by the manufacturer is evenly applied.

Roof mastic impregnates fiberglass and adheres well to the base. Subsequent layers are made in the same way.

Membrane roofs. This option is used for roofs with a small angle of inclination. Polymer membranes with high strength are used as coatings for roofing.

The panels are welded together using hot air or special self-vulcanizing tapes. The main advantage of this coating is simple and quick installation.

Membrane materials are mounted on flat bases, it is possible on an old roof. For welding individual panels, hot air is used (building hair dryer or a special welding machine).

Sometimes for these purposes, a special adhesive tape is used, which has a double-sided adhesive surface.The membrane sheet to the roof is attached to the adhesive composition or mechanically (screws or nails).

Sheet materials for roofing. This group of material includes slate, ondulin, steel roofing sheets, corrugated board, metal tiles. This material is great for pitched roofs.

With all the variety of choices, the installation technology of these materials has much in common: the roofing sheet is attached to the crate using self-tapping screws, nails or other fastening material.

From sheet material, you can also mount budget roofs (for example, using slate) and create elite coatings (for example, from copper).

Type-setting or piece roofing materials. This cereal includes various types of piece tiles: natural, polymer-sand and cement-sand.

Piece materials are attached to pitched roofs. If the slope of the slope is 50 degrees or more, then the tiles need additional fixing with clamps or screws.

It is very important to correctly assemble the roof structure, because the weight of natural and cement-sand tiles is quite large.

Natural roofing materials. Despite the fact that the use of natural materials is a traditional option for building a roof, today only elite coatings are mounted using them.

An example would be reed or slate roofing.

Installation of a roof made of natural materials is a difficult job that can only be entrusted to experienced teams of craftsmen. During installation, it is very important to observe all the subtleties of technology, only in this case, the natural roof will serve for decades.

conclusions

In modern construction, a variety of types of roofs are used.In order to choose the most successful option for this project, which will suit the developer both in terms of price and quality, it is better to seek advice from specialists.

Did the article help you?