All existing materials can be divided into several groups according to the technology of their production and installation:

- leafy

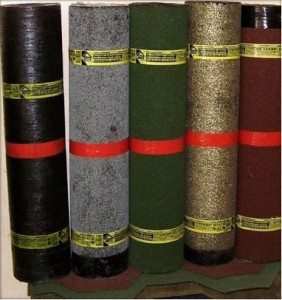

- Rolled

- Small-piece

- Bulk

You can also combine the raw materials used:

- metal

- bituminous

- natural

- Polymer

ADVICE! When evaluating which roofing material is better to choose, one should focus not only on its aesthetics or cost, but also on the load that it will create on the rest of the building structure.

At the same time, groups can intersect in the most bizarre combinations. Therefore, it is still worth deciding on the physicochemical properties of materials.

Metal has been used in roofing for a very long time, at least since ancient times. He has always attracted builders with ease of giving the desired shape, strength and durability. These same qualities are inherent in him now.

The bulk of modern metal materials for roofing is produced in the form of sheets, although galvanized iron is sometimes used in roll form, which reduces the number of joints.

In terms of service life, copper, aluminum, and new roofing material- titanium-zinc, all of them can last 100 years or more.

Galvanized steel and materials from it - corrugated board, euro tiles, can last about 50, however, their service life can be extended by painting or applying a polymer coating.

- Laying technology

All metal roofs are mounted on a wooden crate with a step of 30-50 cm. Galvanized steel materials are laid in a row, with sheets overlapping in vertical and horizontal rows.

The rest are fastened in a folded way - their joints in all rows are flattened, either directly during installation, or even before the material is lifted onto the roof.

- Physical and chemical resistance

Galvanized iron and its materials are prone to corrosion. All materials tolerate physical impacts perfectly

- Labor intensity and terms of work

Installation is relatively easy, the terms are fast, difficulties arise in the case of a complex roof topography, as well as at the junctions with chimneys, pipes, and other structures. They are caused by the large size of the sheets.

- Load on the supporting structures of the building

All materials are lightweight, so the roof is light, does not require a powerful truss system

- Durability

High. 50 years for galvanizing and more than 100 years for other metals

- Aesthetics:

for galvanized steel, corrugated board and uncoated aluminum - low. Other materials have a high

- Special properties

all materials have poor sound insulation. Sheets are subject to bending deformations, therefore, they require careful equipment with wind protection.

- Price

Galvanized steel and materials from it - medium, other metals - very high. Maintenance is practically not required - except in emergencies.

Roofing bitumen has a fairly long history, and have gone through a certain path of evolutionary development. For flat and low-slope roofs, they still remain a practically uncontested solution.

This group is now produced using bitumen-mastic mixtures on synthetic bases, which did not eliminate all problems. However, in terms of speed and cost of coverage, especially for large areas, it has no equal yet.

The material is also used as a waterproofing layer for other types of roofing. The same group includes eurotile, which is a cut mastic-bitumen sheet. But in terms of laying technology and properties, it is closer to piece materials.

On the basis of bituminous mastic, self-leveling roofs are also made, but their properties differ significantly from rolled ones - they are more technologically advanced, more durable and more plastic.

- Laying technology

The reverse side of the material is covered with a layer of mastic. This layer is melted with a special burner, after which the heated part of the canvas is pressed against the base. In the case of a truss structure, it is launched along a solid wooden crate, on a flat roof - along a floor slab. Stacked in two or more layers with overlap in rows.

- Physical and chemical resistance

Low - does not tolerate contact with solvents, liquid bitumen, high and extremely low temperatures. Easily damaged by mechanical impact.

- Labor intensity and terms of work

Minimum. In simple cases, very large areas can be covered in one day by a crew of three.

- Load on the supporting structures of the building

Minimum - up to 8 kg / m2 of roofing (when laying in 2 layers)

- Durability

Low. Up to 25 years for the best samples, less than 10 for the worst

- Aesthetics

when using colored sprinkles - medium

- Special properties

the material is extremely combustible and has a relatively high hygroscopicity.

- Price

roof material and production is cheap. However, in the future, frequent maintenance and repair is required, which increases operating costs.

ADVICE! It is more cost-effective to repair damaged areas of bituminous roofing using mastic for self-leveling roofing. It will reliably close the formed holes, and will not allow them to grow in the future.

Natural materials are presented in the categories of small pieces and sheets. In the latter, these are asbestos-cement and cement-fiber sheets.

In the first - a lot of materials:

- tiles ceramic

- cement-sand tiles

- slate

- porcelain stoneware

and a whole group of wood materials. Sheet natural materials are similar in characteristics and technology to other sheet materials. However, they are distinguished by their large weight and comparative fragility to impact.

Advice! When choosing the type of roof, one should correlate its compatibility with the general engineering solution of the house. For example, the installation of a tiled roof on a frame building will require such reinforcement of the structure that the very principle of modular construction in this case will lose all meaning.

Mineral materials

- Laying technology

All small-piece materials are laid on a continuous crate with waterproofing. As a rule, the laying technology is in-line, with elements meshing with each other using their own relief.

The exception is bituminous tiles, which are fastened with nails. The elements are laid in rows, starting from the roof overhang. For junctions, valleys and other irregularities of the roof, special shaped products are used.

- Physical and chemical resistance

High, except for extreme impact loads. They also do not tolerate freeze cycles, begin to crack when the quality of the material or styling is poor.

- Labor intensity and terms of work

Extremely large. Greater precision and high qualification of specialists are required. Eurotile - medium.

- Load on load-bearing roof structures

Extreme. They require a very powerful truss system and reliable load-bearing walls. The weight of 1 m² of roofing can reach 40 kg. Eurotile - the weight is small, the rafters can be lightweight.

- Durability

At the level of the best metal materials - up to 100 years or more. For euro tiles - comparable to rolled materials.

- Aesthetics

The best among all roofing materials, maybe with the exception of wood

- Special properties

In addition to metal tiles, all materials are fireproof, all without exception are quite easy to repair, do not require maintenance, except for emergencies

- Price

Excluding shingles - one of the highest among all classes

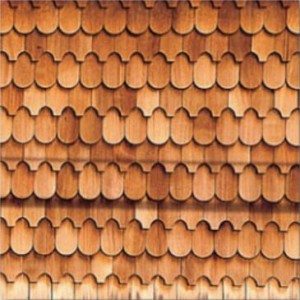

Wooden materials are probably the most ancient roofing. In addition to the board (tesa), which is used only for sheathing outbuildings, the rest are piece.

Among them:

- Shingles

- Shingle

- plowshare

- Shindel

All high quality materials are made exclusively by hand. Only a few, selected species of wood are used. Roofing works especially effectively with wooden log cabins, having the same physical properties with them. The most environmentally friendly material.

In terms of properties, in addition to weight and fire resistance, it repeats other in-line materials. Frost-resistant. It is attached to the crate with nails.

Polymeric materials are newcomers to the roofing market. Their main representative is Euroslate, a class of sheet materials made of bitumen and synthetics, with which the fibrous frame is impregnated.

The materials are very promising, possessing in many respects unique properties. Thanks to their artificial origin, they can receive a variety of performance characteristics from their creators.

- Laying technology

Similar to regular slate

- Physical and chemical resistance

Very high. Except for point impact loads and certain types of solvents

- Labor intensity and terms of work

The best among all classes

- Load on load-bearing structures

Minimum

- Durability

At the level of galvanized iron materials

- Aesthetics

above average

- Special properties

Relatively low fire safety. Easy to repair, virtually maintenance free.

- Price

One of the lowest among quality materials

A complete analysis of the advantages and disadvantages of all materials is a matter of academic works. But a preliminary comparison of roofing materials is an opportunity to pay attention to something you like, and then study it in more detail.

Did the article help you?