The modern building industry is developing new materials, using innovative solutions and traditional methods to facilitate the task of building multi-storey buildings and private houses. It is rather difficult to explain what kind of material it is - filisol.

Filizol - what kind of roofing material is it

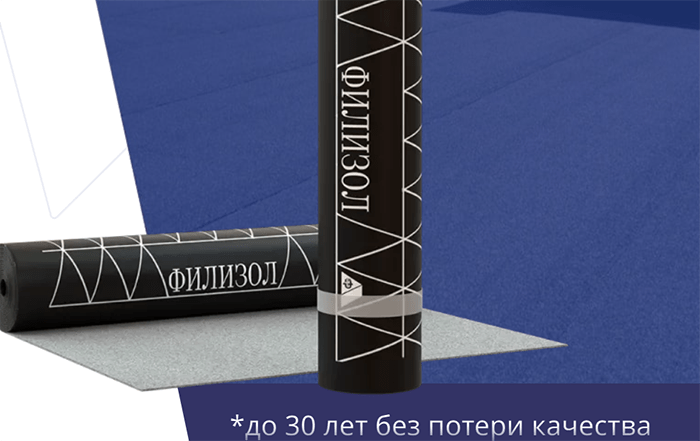

Over time, it became possible to build a built-up roof - an environmentally friendly and breathable material with excellent waterproofing properties, and more recently with a stylish design.

Filizol roofing material is:

- an excellent option for the construction of a built-up roof;

- manufactured in the construction industry in different brands;

- the composition and purposefulness, the possibilities of application, the basis for installation depend on this designation for the consumer;

- there are options for the top layer and substrate, for the bottom layer of the roofing carpet;

- can be used for waterproofing not only buildings, but also tunnels, bridges, various functional structures.

Interesting! Argon disc welding

The simplest answer is what kind of material Filizol is - a material made on a bitumen basis. It happens rolled, roofing. It is used for roof waterproofing. Since bitumen is a relatively short-lived solution, the technology provides for variable modifications, the addition of a glass base, polymers of various types. It is possible to determine what kind of material it is, as in any other case, according to the approved marking from the manufacturer, some of its types are recorded in GOSTs and have been manufactured for more than a year.

Specifications

The widespread use of the material in construction is due to ease of manufacture, ease of installation and long-term use, if everything is done correctly. Differentiation of products, united under a common term, is carried out according to different principles:

- use in the production of fiberglass or polyester non-woven fabric;

- width - from 950 to 10 thousand mm;

- degree of biostability;

- Possibilities of application in laying, arrangement of the bottom layer, repair and waterproofing.

Filisol brands

Usually, there are two types of filisol in rolls: for arranging the upper (with polyester non-woven fabric as a base, and the lower layers - using fiberglass). However, there are also brands for a single-layer roof, as well as insulating, which refers to lining materials. Some manufacturers have Filizol-super in their product range.

Interesting! Geotextile dornite - what is it: specifications, non-woven, in rolls

Brand N

It is appropriate to start the list of types of rolled roofing filizol with the H marking, which is used to create a lower, base layer or create a full-fledged waterproofing for further multi-layer coating. It has its own characteristics - a protective fine-grained powder or a film of polymer material that is easy to melt. The manufacturer guarantees that it will last at least 25 decades, provided that the top layers are properly installed.

Grade B

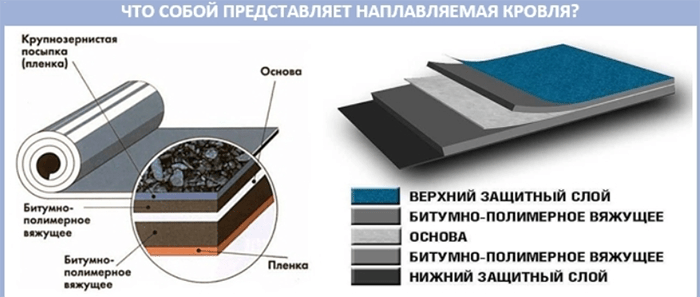

It is used to create the top layer of filizol, differs in structure and composition from that marked with the letter H. In it, one of the sides is covered with coarse-grained dressing, and the second with a fine or melting light polymer film. Roofing material Filisol grade B may consist of a base, two bitumen-polymer layers with astringent properties, top and bottom protective coating. The minimum breaking force of any of the layers differs depending on the material used - fiberglass, fiberglass and polyester. The binder is standardly calculated up to -35°C, but the workable range is considered to be from -50 to +120°C.

Other options

Grades K and KX of rolled roofing filisol - for the top layer of a multilayer coating, H and HX - for the bottom, there are differences in the properties of materials, and this is not accidental, since they are designed to perform different functions. A clear illustration is the marking P, which indicates the belonging of the insulating composition to protect against moisture ingress of residential, public and industrial buildings, bridges, crossings and tunnels for transport.

Super

The name is not accidental, a heat-insulating and mastic layer, 2 protective coatings and 2 - bitumen-polymer, with astringent properties, have been added to the usual composition. Together with the base, it is a seven-layer filizol, the characteristics of which correspond to the eloquent name. It also has subspecies based on the use of fiberglass, polyester non-woven fabric, or a combination of both. Fine-grained dressing may be absent, and a fusible film of polymer material may be used instead.

Who is the manufacturer

The demand for the material means the appearance of numerous offers from manufacturers. Offers may differ not only in types, but also in budget.

Roofing material Filisol brand B and other popular products with the markings listed above may also differ by category - from economy class and standard to premium.

One of the most famous is produced by a domestic enterprise with a long-term proven reputation called "Filikrovlya". In order for the installation of filizol to go smoothly, and not bring any inconvenience or financial costs, it is better to contact the website of this well-known manufacturer, and not look for goods of completely incomprehensible etiology in various stores.

Production technology

There is executive documentation, which specifies the scope, organization and production technology. The instruction begins with the observance of safety precautions, the reliability of fastening of all structures and devices used. Material rolled roofing filisol grade B is treated on both sides with an astringent coating. The outer layer is covered with a coarse-grained dressing, the inner layer is covered with a material with small granules and a film.

Filizol N roofing material is produced according to the algorithm provided for by the instructions and technological standards. All this happens in compliance with safety regulations and permanent control at every stage of production.

Material Application

It is determined by its labeling, which hides the features of the production cycle and the intended purpose, determined by the composition and technology:

- marking B means that the material is used to create the top layer of the welded roof;

- Filizol N rolled material - for the base (lower) coating during the construction and repair of roofs;

- the intended purpose may be determined by the width of the product, the presence of additional layers, the base used, the crumb or film coating.

Impact resistance, elasticity, fast gluing of the roll, the ability to do without repair for a long time, provided that it is properly installed - all these are the reasons for the demand for a popular building and insulation material.

Favorite material of designers

The advantages of this technology are clear: you can not only repair a leaky roof, but also quickly and inexpensively recreate it from scratch. The increase in the price of building materials is associated with closed borders and customs duties. But the high cost is also due to transportation costs and labor costs. Filizol is an excellent way out of this situation.

Advantages and disadvantages

There are many more benefits to using. These include:

These are just some of the bonuses for the average manufacturer and industrial companies.

The disadvantages include:

But there are very few shortcomings, so they can be found in reviews quite rarely.

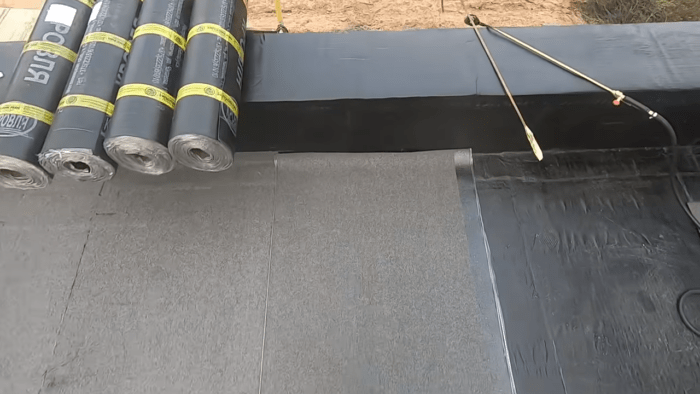

Laying technology

Depends on the scale of work, the width of the canvas and the type of material used.General description - cleaning and drying of the base, insulation from steam, thermal insulation, arrangement of a cement screed, on which the fabric from the main roll is glued. After that, you can make an additional protective layer. Instructions for organizing the construction process using a convenient building material mentions the features that are determined by the nature of the base. It can be concrete slabs or other building innovations.

Filizol is a modern material. Innovative technologies are involved in its production. It is used for the construction of multi-storey buildings and private houses.

Did the article help you?