Shingled roofs have been used since ancient times and are still very popular today, especially in the construction of houses whose architectural style imitates antiquity. This article will talk about what shingle roofing is, what materials are used for it, and how the roof is covered with shingles.

Shingled roofs have been used since ancient times and are still very popular today, especially in the construction of houses whose architectural style imitates antiquity. This article will talk about what shingle roofing is, what materials are used for it, and how the roof is covered with shingles.

A shingle roof is a lightweight roof that has a number of positive characteristics, which include:

- Environmental Safety;

- Long service life;

- Resistant to winds and low temperatures;

- No noise from wind, hail, rain, etc.

It is also important that this plank roof is able to "breathe", so that condensation does not form in the space under it.

The disadvantages of shingle roofing include a rather high cost, as well as the complexity of installation, which can only be performed by highly qualified specialists.

These disadvantages are offset by the fact that this roof, which is covered with special roofing boards, is the most durable type of roof and has a fairly long service life if all basic installation requirements are met, such as:

- Use of quality wood;

- Correctly selected slope angle;

- Quality work performed by installers.

Experienced roofers claim that the life of a shingle roof directly depends on its angle of inclination, that is, a roof with an angle of 50 degrees will effectively last 50 years, although, of course, this does not mean that a horizontal roof will collapse in the very first year of service.

In addition to the slope, a very significant influence on the service life is the correct installation. Roofing shingles should be nailed to the battens, leaving sufficient ventilation clearance.

However, if the gap is not sufficient or if the installation is done directly on an airtight film or bituminous coating, this will cause damage to the material, despite its high resistance to weathering and rot.

Material selection

Roof shingle is made from the following wood species such as Canadian Red Cedar, Larch, Oak, Resin Pine, Aspen, etc.

The distinguishing features of oak include strength, strength, high density (about 690 kg / m3), hardness and heaviness. Upland, holm or oak oak grows in sandy, dry places, such as pine forests and oak forests.

The wood is usually yellow-brown or greenish in color. oak wood like roof material it is easy to process, lends itself well to finishing and bending. In addition, the advantages of this material include wear resistance, high strength and a rather beautiful texture.

Since wooden roofs, the average weight of which is 15-17 kg per square meter, are classified as medium-weight roofing, they do not require the installation of a bulky and complex rafter system.

For laying wooden tiles (spindle or shingle), it is necessary to perform a step-by-step crate using bars with a section of 40x40 or 50x50 mm.

In the case of a plank length exceeding 80 cm, a bar of a larger section is chosen. An important advantage of a wooden roof over other types of roofing materials is the absence of condensation in the under-roof space.

The water absorption of oak wood is significantly lower than the moisture absorption of pine due to its higher density. Therefore, oak shingle roofing, unlike larch or cedar, requires additional processing, making it resistant to decay.

In the production of shingles, one of the most suitable types of wood is Siberian larch, which occupies a separate place among all conifers.

Siberian larch wood, which has a reddish-brown, less often brown color, has good strength and resistance to moisture, and also practically does not warp.

Useful: larch wood is slightly inferior in hardness to oak, but at the same time it is more durable, and its strength increases over time due to the non-standard composition of its resin.

The shingle, made from Siberian larch wood, has a number of advantages inherent in this particular breed:

- The high density of this wood and the high resin content in it provide excellent resistance to decay and damage by pests;

- Higher, than at other breeds of wood, temporary resistance to wear;

- Beautiful wood structure;

- Availability of this material;

- High shelf life, up to 100 years, depending on specific conditions.

Making shingle

For the manufacture of high-quality shingles, even parts of tree trunks located between the branches with a small number of knots are used.

First, using an ax and a hammer, blanks are obtained from the logs in the form of wedges, the thickness of which does not exceed 20 mm. Next, the workpieces are manually finished using a cutter, as a result of which a teardrop-shaped part with a thickness of not more than 10 mm is obtained.

A groove is made in the part for fastening, after which it is thoroughly dried. The highest quality shingle is considered, the drying of which lasted at least 6 months.

Before laying, the shingle plates are treated with anthracite oil. After the completion of roofing work, they should be painted with a special composition.

In industrial production, the manufacture of shingles is carried out by two methods: sawing or splitting. The material obtained as a result of splitting by hand is of higher quality and has a more even surface.

Sawn shingles are characterized by roughness, which leads to increased absorption of moisture and, as a result, rotting.

Split shingle, which is more popular with professional roofers, can be made independently:

- The log, whose diameter is about 30-40 cm, is sawn into several pieces about 40 centimeters long each.

- The resulting pieces are cut with an ax, resulting in plates with a thickness of 8 to 10 cm.

- With the help of a mallet and a blade, these dies are split into shingle boards, the thickness of which is 8-10 millimeters. To do this, clamp the die in a vise and apply jerky strong blows with a mallet on the blade mounted on the part.

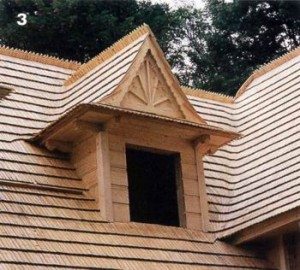

Types of shingle roofing and their installation

When laying a shingle roof, you should first of all treat the shingles with an antiseptic solution. Laying is done in such a way that the sharp edge of the laid plank fits snugly into the groove of the adjacent one.

At the same time, the details that make up the upper rows of the coating must overlap the joints of the shingles laid earlier, fixing them with nails.

The roofing cornice is finished with a board, the thickness of which corresponds to the thickness of the shingle coating. On the ridge of the roof, the shingle is butt-jointed, after which the corner is upholstered with boards.

There are two main ways of laying shingle roofing: in one and two layers.

Laying shingle in one layer is performed as follows. The plates are fastened starting from the bottom edge, moving up. At the same time, parts are laid with an overlap of 10 to 15 cm.

For coverage roof ridge use boards or sheets of steel in the case of a domed roof.

Important: Laying of rows of shingle plates should be carried out along lines parallel to the ridge and the edges of the roof.

For fastening the shingle plates, a rare wooden crate is made. For this, bars are used, the distance between which should be 40 centimeters.

It should also be ensured that the strip of shingle covering by 8-10 cm overlaps the roof eaves, as well as the ridge. To fix the parts on the crate, shingle nails are used.

Two-layer shingle roofing is basically produced in the same way as described above. The shingle plates are placed on a crate made of beams, the distance between which is 40 cm.

At the same time, the rows roof coverings should be laid out not from one, but from two layers of shingle plates, and the laid parts should alternate with the seams of the joints.

Important: when laying the shingle in two layers, double the amount of material should be prepared in advance.

The fixing of parts is carried out in such a way that each subsequent one overlaps the previous one by 10-15 cm. Laying the shingle on the ridge on the leeward side of the roof is carried out so that the width of the lined row is 8-10 cm

To improve the appearance of the roof and give it the shape of a wedge, shingle plates are laid at the corners and in the groove with a hewn edge.

Sometimes it is recommended to use small parts at corners, the width of which is 6 mm, the length is from 30 to 40 cm, and the width does not exceed 10-12 cm.

In addition, parts made in the form of scales, pointed or pointed at one end, are suitable in this situation.

Larch shingles can be fastened with galvanized nails, screw or grooved nails made of high quality steel, or with zinc coated wood screws.

Roofing staples or nails can also be used to fasten boards.

Important: the use of raw or uncleaned nails for fastening can lead to blackening and subsequent rotting of the surface of the shingle.

Nail heads should be driven flat against the surface of the shingle, and shafts should penetrate at least 18-20 millimeters into the wood of the supporting bar.

Each shingle is fastened with two nails driven in at a distance of two centimeters from the edge of the shingle.

At the same time, it is necessary to deviate from the chamfer by about 2/3 of the length of the shingle, which will later allow the nail heads to be covered with subsequent layers of the coating, protecting them from harmful atmospheric influences. This leaves the bottom of the shingle free to dry and expand.

Shingled roofs have been used since ancient times and enjoy well-deserved popularity in our time.

This is a wooden roof - light and durable, with high reliability and long service life, as well as giving a unique appearance to the roof of the house, and therefore to the whole house as a whole.

Did the article help you?