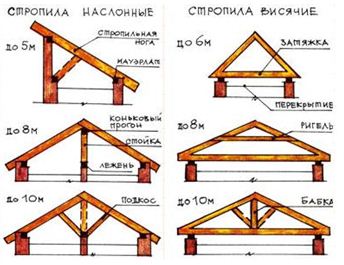

The truss structure is the basis for any pitched roof, its "skeleton". It takes on very serious loads, especially in winter, and is the carrier for the roof. This means that the protection of the house from precipitation and wind exposure largely depends on it.

Therefore, in individual construction, the manufacture of rafters at the final stage is an important operation, which is given special attention. What is the sequence of actions when constructing a rafter system, what features do different types of rafters have - later in the article.

Given the exceptional importance of the truss system, its type, material for manufacture and other important details are determined at the design stage. roof trusses usually made of wood or metal (in unique cases in private housing construction - of reinforced concrete).

Metal trusses are usually prefabricated, delivered ready-made to the construction site and installed with a crane, fixed by welding.

Wooden rafters can:

- Also manufactured in a factory way (hanging rafters)

- Individual structural elements can be manufactured in a factory way and assembled at a construction site

- The entire truss system is cut and mounted directly on the object

The use of factory semi-finished products implies the utmost accuracy in complying with the project during construction work, since the alteration of finished trusses or changing the size of their parts is associated with great difficulties, and sometimes it is simply impossible.

But the advantage of this solution is that if the walls are displayed correctly, then installing the truss system is tantamount to assembling a children's designer.

Often, factory products are used in the construction of complex roofs, for example, if a truss system is required over a bay window, and without fail - in the construction of prefabricated buildings supplied as a set.

Advice!!

Before self-manufacturing and assembling rafters, you should study all the terms associated with the roof. Confusion in concepts can lead to unpredictable consequences in the course of work.

In the process of installing a truss structure, the following stages can be distinguished:

Making templates, cutting, making trusses

Patterns and sawing

Of course, the most important thing in the preparation of patterns will be the manufacture of templates. rafter legs. This operation should be especially strictly approached on roofs of complex configuration, for example, when attic rafters are installed.

It can be done in the following ways:

- A rail is taken, the length of which is equal to the vertical distance from the top of the supporting wall to the ridge (ridge beam or rafter joint).

Perpendicular to it, a board is stuffed along the edge, the length of which is equal to the distance between the outer walls of the building.

The design should be immediately checked "in place" by installing it on the walls and repeating the measurements.

If the geometry is observed, it is possible to make a template for the rafters along the top of the vertical rail and the edge of one of the side ones. It is necessary to immediately take into account the margin for joints, roof overhangs, etc.

Advice!

When the template is measured in length, it is better to immediately apply all the cuts, tie-ins, attachment points of the connecting elements to it.

You can make separate templates for all this, and apply them to the cut rafters in an independent operation, but this increases the risk of errors.

- This method is a subspecies of the first, but the perpendicular board is not stuffed along the edge of the vertical, but in the middle.

Then, with the help of additional rails or a cord, the necessary slopes and distances to the walls are determined, after which the algorithm of actions is the same.

This method is used more often on houses with a large span, where the use of a "full-sized" horizontal rail is difficult. - You can take two planks, hinge them along one of the edges with one nail, and, having installed them on the walls, measure the desired length of each, check the geometry of the structure, and then fix the connection with 3-4 self-tapping screws.

This method, although very simple, is considered the least reliable.

Advice!

In templates with a vertical bar, the latter can itself be used as a template for supporting elements, if such are provided for by the design of the rafter system (for example, racks or headstock)

Cutting rafter legs and other elements can be carried out both on the ground and on the floor of the building. Each of the options has its advantages and disadvantages: it is more convenient to work on the ground, and ready-made farms can be assembled (however, they rarely have sufficient strength for this), on roof - you can immediately try on the finished part, and, if necessary, correct the flaws.

And, for example, a bay window truss system simply requires assembly on site, since it can have a rather complex configuration, and it is easier to mark the rafters right away than to waste time and effort on separate templates.

Truss assembly

Farms, in any case, end ones, it is better to pre-assemble "profit" without making capital connections - after all, it is the rafters located above the gables that will play a decisive role in the correct geometry of the roof, so they should be measured and installed especially carefully.

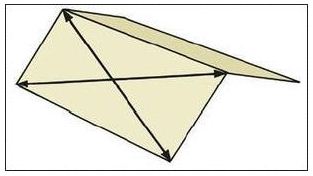

First of all, these structures must be installed strictly parallel to the wall on which they are installed, and also have a strictly vertical position.This is checked in the following way: the trusses are temporarily fixed, strings are stretched from each of the lower corners of each truss to the top of the opposite.

The result is diagonals on each of the slopes. If the roof is broken, angular or has another complex shape, measurements must be made for all its flat planes.

As a result, if the slope geometry is correct, the following results should be obtained:

- At the intersection, the strings should lightly touch each other.

- The place of their intersection should be in the middle of the length of the roof

- They should intersect at half the length of opposite rafter legs.

If any of these conditions are not met, the offending farm should be adjusted accordingly until the problem is corrected. After that, the elements can be fixed to the rafter beam thoroughly - with the help of twists or staples.

After that, in the case of layered structures, if provided for by the project, a ridge beam should be installed between the trusses. If a chalet truss system is used, where gable walls are provided “under the ridge”, the same operations should be performed for the walls themselves before installing the outer rafters, since they will rest on the walls.

In this case, possible inconsistencies are eliminated with a leveling screed. To align the subsequent rafters, use twine stretched over the ridge.

Technical details

To connect the rafters with the rafter (Mauerlat) and other parts of the system, various types of carpentry "locks" are used: a tooth, a double tooth, a spike, etc.The choice of a specific method depends on the shape of the roof, the planned load on it, the features of the operation of a particular node (for compression, tension, bending, fracture).

Recently, almost any type of connection is duplicated with special metal plates.

Advice!

In most cases, when installing layered rafters, it is worth arranging a swivel joint in at least one of the nodes: fastening to the Mauerlat (special sliding metal structure), connection with the ridge beam, rafter joint (if there is no ridge beam)

It should be noted that in layered rafters, in the presence of a ridge beam, it is allowed to install the rafter legs not strictly opposite each other, but with an offset - so that the rafter legs touch the sides. In hanging rafters, this is unacceptable, since their principle of operation is based precisely on the emphasis of the rafters on the ends.

But, no matter which system is chosen, before making rafters, you should thoroughly study the theory and try your carpentry skills in practice. If both are in order, the finished roof will last a long time and will not move anywhere.

Did the article help you?