The rafter system is an important element of the roof structure, the reliability of the future roof depends on the correct calculation of which. This article describes how to calculate and manufacture a truss system for a metal tile, special attention is paid to what should be the step of the rafters under the metal tile.

The truss system for metal tiles is calculated at the design stage of the roof, while taking into account the design features of the frame, the shape of the future roof and the wind and snow loads of the region. The pitch of the rafters and their type is chosen depending on the design loads on the roof.

Brief instructions for installing the rafter system and calculating the pitch of the rafters are given below.

In central Russia, the total load on the roof covering from snow and wind is usually taken to be 200 kg / m2. In the northern regions, this value can be two and a half times higher due to the large amount of precipitation in the form of snow.

It is necessary to correctly calculate the loads, since the service life and reliability of the system itself directly depend on this. rafter systems, and the totality of elements of which it consists, i.e. valley + rafters + lathing, etc.

In case the design load is 200 kg/m2, the step between the rafters should be 600-900 millimeters. The recommended dimensions of wooden rafters are 150x50 or 100x50 mm.

If the calculated load on the rafter system has a higher value, the rafter pitch should be reduced to 500-600 mm.

It is also recommended to make a transverse additional crate using boards with a thickness of 15-20 mm. Due to this, both the rafter system itself and its elements will have the required rigidity, and the load on the structure will be distributed more evenly.

Important: when installing rafters under a metal tile, it is necessary to treat them with special fire-fighting and antiseptic preparations to protect them from mold, decay and insect damage.

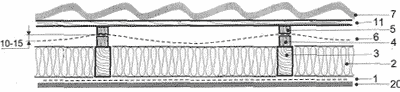

Rafter system and its waterproofing

- vapor barrier

- insulation layer

- rafters

- Intermediate crate

- Control grille

- waterproofing layer

- metal tile

- crate

- Ceiling

When erecting rafters, it should be borne in mind that their most optimal step (3) is 600-900 millimeters.It should be taken into account that more rafter step requires the use of boards of a larger cross section for lathing.

For rafters, bars are used, the cross section of which should be at least 150x50 millimeters. All available space between the rafters is covered with insulation material, while a gap should be left between the insulation and waterproofing to ensure ventilation of the insulation to protect it from moisture.

For this to rafters an intermediate crate is nailed, the height of which is 50 mm.

The waterproofing is rolled out parallel to the eaves in a horizontal plane. The overlap of the next layer is at least 150-200 mm in case of a roof slope exceeding 30º and 250 mm for a slope angle of 12 to 30 degrees.

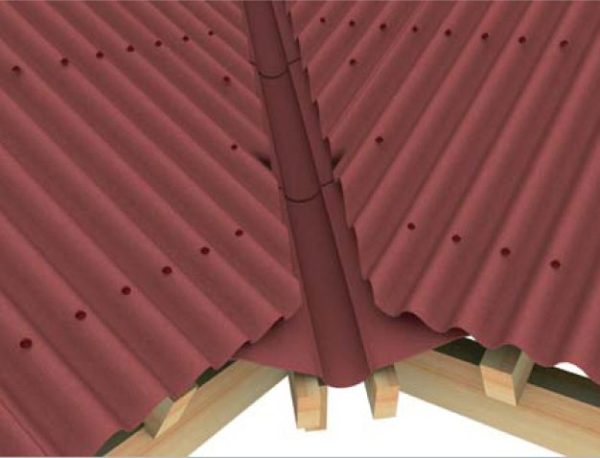

Important: for hip roof ridges, the overlap should be increased by an additional 50 millimeters.

The joints of the waterproofing material are located under the counter-lattice, their overlap must be at least 100 mm, and the use of a connecting tape can be dispensed with.

Important: it is impossible to mount the waterproofing "in tightness".

A sag of at least 10-15 mm should be provided, which should be uniform across the entire width of the material layer.

The distance between the film and the insulation should be at least 30 mm, these layers should not touch each other.

A significant disadvantage of this method is the weathering of heat along with steam by air flows. Therefore, waterproofing is more effective, which has a high vapor permeability, while maintaining serious water pressure.

This type of waterproofing also serves as a windproofing, and when laying it, it is not necessary to observe the distance from the insulation layer.In addition, there is no need to install an intermediate crate.

Lathing under the metal tile

If a metal tile is chosen as the roofing material, then the first step is to install the truss system under the metal tile.

This is due to the fact that the roof is calculated depending on the loads experienced, which include:

- Self weight of the roof;

- The weight of a person performing repair or maintenance work on it;

- Loads of snow and wind, etc.

The self-weight of the roof largely depends on the material of its coating. So, weight 1 m2 a natural tile is about 50 kilograms, and a metal tile weighs from 3.6 to 7 kilograms, respectively, the costs of their rafter structures also differ.

The total weight of the rafter system is also influenced by the sum of the weights of its individual elements: rafter + valley + crate, etc. Depending on the design of the roof, certain requirements are also imposed on its crate.

Rafters for metal tiles are made of coniferous wood boards, the size of which is 150x50 mm. The step (distance between the centers of adjacent rafters) of the rafters is 600-900 mm. To ensure effective runoff of rain and melt water, the roof slope must be at least 14 degrees..

Before proceeding with the installation of the crate, it is recommended to perform the following work:

- Installation of a frontal board nailed to the lower end parts of the legs of the rafters;

- Roof overhang filing, for this you can use siding, boards or metal tiles.Ventilation holes should be provided in the filing, which will ensure the flow of air into the space under the roof, especially in the case of its subsequent insulation;

- Installation of hooks to which the gutter will be attached. Their fastening is usually made to the rafter legs. Short hooks are attached to the ends, and long ones - over the legs of the rafters;

- Next, the waterproofing film is laid.

Thanks to this, the valley truss system, the attic and other under-roofing elements will be reliably protected from condensate that forms on the inside of the roof covering, as well as from leaks that may occur in leaky areas of the roof:

- Film strips should be laid from the bottom up, perpendicular to the direction of water runoff. In this case, the strips should overlap each other by at least 15 cm.

- The lower edge of the first strip should be hung into the gutter for the drain. The upper strip ends under the ridge, without bringing it to its upper part. This will create a gap between the roof and the film, providing ventilation.

- Sealing the joints of the strips is carried out using a special tape.

- The sag of the waterproofing should be approximately 2 cm, which avoids its ruptures during temperature deformations and displacement of the rafters.

- The initial fastening of the film is carried out using a stapler. Then it is additionally fixed with the help of counter-lattice bars, the cross section of which is 50x50 or 50x30 mm.

Next, you can proceed to the installation of the crate. For this, boards are used, the section of which is 100x32 or 100x25 mm, or bars with a section of 50x50 mm.

The installation of the crate is carried out in several stages:

- At the bottom of the legs of the rafters, the initial crate is attached, which is a board, the top of which is beveled in a horizontal plane. The height of this board should exceed the bars or boards of the crate by a wave height of 1-2 cm, since it fits under the top step of the metal tile;

- From the side of the gutter for the drain, a cornice strip is attached to the initial crate;

- The lathing is being laid, while the distance between its centers should be equal to the pitch of the metal-tiled profile, which is usually 35-40 cm;

- The distance between the initial and subsequent lathing should be 5 cm less and is usually 30-35 cm, since the metal tile is placed in depressions on the lathing and ridges on the initial lathing;

- In the area of \u200b\u200bthe ridge, two boards of the crate are laid in a row;

- At the installation sites of elements such as attic windows, protruding elements, the truss system consists of many parts, they perform a continuous crate.

The rafter system is designed to ensure reliable laying of roof insulation layers and roofing material. The durability and efficiency of the constructed roof depends on how the calculation of the rafter system, in particular, the pitch of the rafters, depends.

Did the article help you?