Sheds covered with corrugated board have recently become more widespread in private construction. This article will talk about what advantages they have, where they are used and how do-it-yourself canopies are made from corrugated board.

Sheds from corrugated board can be used in a variety of elements of a private house:

- carport;

- canopy over the porch;

- canopy over the barbecue or playground;

- outbuildings in the form of sheds, etc.

The main advantages of a corrugated canopy

Consider the main advantages that canopies and visors from corrugated board have:

- Profiled sheeting is the most common roofing material, for the manufacture of which galvanized steel 0.5-0.8 mm thick with a protective polymer coating is used..

The height of the sheet for the construction of a small structure is 10-44 mm, the length is 2-6 m, and the width is selected in the range from 800 to 1100 mm. The estimated number of sheets required for the manufacture of canopies depends on the working area, and the overlap of the sheets should also be taken into account. For a sheet with a length of two meters, the working area is 1.68 m2. - Profiled sheets themselves have a rather attractive appearance, which eliminates the need to apply additional decorative coatings on them.

- The material has fairly good quality characteristics: high resistance to various mechanical damage, long service life, resistance to low temperatures.

- The dye used in the production of sheets has good resistance to ultraviolet radiation and does not fade when exposed to sunlight.

- During the operation of the corrugated board, there is no release of various harmful substances into the environment.

- Unlike most other roofing materials, corrugated board is non-flammable and non-flammable.

Carports

Currently, all car owners are trying to acquire an individual garage for their car. During the construction of a cottage or a country house, the project also necessarily takes into account the location and area of the garage.

This quite often leads to problems associated with the insufficient size of the site or lack of funds. An excellent way out of this situation is a corrugated carport, which can be equipped even in a small summer cottage, and its construction will cost a fairly small amount.

A canopy made of corrugated board not only saves money, since its cost is much lower than the cost of a capital garage. In addition to a place to protect the car from the sun and rain, such canopies can be used as shelter for residents or guests of the house, for example, from the hot sun or heavy rain.

Such canopies do not lose their relevance all year round, acting as protection from ultraviolet rays in the summer, protecting from rain in spring and autumn, and from snow in winter. In addition, carports made of corrugated board save you from spending extra time in winter on digging out a car left overnight from under the snow.

Canopy construction

Do-it-yourself canopy from corrugated board can be assembled quite simply according to the principle of the Lego constructor. Many manufacturers offer convenient kits for assembling canopies, almost ready for use: they only need to be assembled into the desired design.

These kits are delivered to the customer and are assembled right on the spot into a fairly light structure that has an aesthetic appearance and blends seamlessly into the surrounding area. Canopy materials can be made individually with dimensions specified by the customer.

For the manufacture of the frame, either hardwood impregnated with special compounds, or steel or aluminum is used. As a covering for canopies, one- or two-sided corrugated board with a polymer coating is used, a wide range of colors of which makes it possible to choose a shade that suits almost any design of the site and house.

The low weight of the material allows you to make a very light frame, which occupies a fairly small area on the site, which is also one of the advantages that corrugated sheds have. Caring for corrugated board also does not cause much trouble - accumulated dust and dirt can be washed off quite easily with a stream of water under strong pressure.

The installation procedure of the finished kit is quite simple, especially since the kit necessarily includes instructions with detailed diagrams and drawings.

Strict adherence to this instruction in the process of assembling the canopy allows you to perform this work quickly and efficiently, without encountering any problems and using a minimum set of tools:

- Screwdriver;

- Drill;

- Hammer;

- Screwdrivers;

- Construction level;

- Set of wrenches.

To install and fasten the frame, prepare the base in advance, for example, from reinforced concrete slabs. After mounting the frame, sheets are mounted on it corrugated board, which are fastened to the frame profiles using self-tapping screws.

An important advantage of such structures is also the possibility of their quick dismantling, which allows, if necessary, for example, when performing any work on the site, to remove the canopy in a short time, freeing up the necessary space.

Installation of a canopy from corrugated board

Any canopies, regardless of the building materials used, are considered prefabricated buildings. One person can do the work on their construction with their own hands, without resorting to the help of qualified specialists.

This instruction will tell you how to make a canopy from corrugated board.

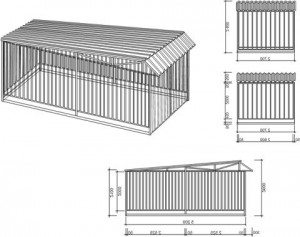

As an example, the most popular type of canopies is chosen - shed:

- Before proceeding with the construction of the canopy, you should prepare the place by clearing and leveling the site for construction, after which they begin to build the frame.

- First of all, support posts made of profile pipes with a section of 40x60 mm are poured with concrete. The step between them is usually one meter. Having calculated the number of racks, they are concreted around the entire perimeter of the base, after which transverse beams, also made of shaped pipes, are attached to the racks.

The slope of the slope of the roof of the canopy is regulated by the difference in the lengths of the support posts located on opposite sides. - After the frame is completed, it is primed and painted with exterior paint. Next, the most crucial stage begins - the direct installation of a corrugated canopy with your own hands.

- Sheets are fastened to the transverse beams that make up the frame. For corrugated board fixings self-tapping screws are used, which are usually used 5-7 pieces per square meter of the surface to be covered.

Important: for fastening the profiled sheet, galvanized self-tapping screws with a sealing rubber gasket are used that do not damage the protective coating of the sheet.

- When laying sheets of corrugated board, an overlap of one trapezoid (one wave) should be performed. This allows you to increase the overall tightness of the canopy roof.

After corrugated board installation completed, we get a finished structure with a shed roof, which does not need to be reinforced with additional stiffeners, since the profile pipe provides the necessary strength.

Installation of a canopy from corrugated board (or such an element of the house as, for example, a canopy from corrugated board) can be done even by a person without building training and any special knowledge. The most important thing is to plan the work in advance and calculate the required amount of building materials, and when erecting a canopy, clarify various nuances in the instructions for the material.

Did the article help you?