Having decided to cover your roof with metal tiles, do not rush to acquire the first thing that catches your eye. Shops and the market offer so many options that the buyer will be confused for sure. Therefore, you definitely need to decide in advance what is most suitable not only for taste, but also for characteristics.

The question of how to choose the right metal tile, we will analyze in detail further.

Main characteristics

- The thickness of the sheets of metal.

- Characteristics of the zinc layer.

- Properties and type of polymer layer.

- manufacturer and material quality.

- The quality and type of profile, the height and shape of the waves and the type of production equipment.

- Roofing color.

As you can see, there are not so many points, however, it is advisable to consider each of them in more detail, and take this very carefully. The duration and quality of its service will depend on how carefully you choose the material.

What should be the thickness

Manufacturers produce metal tiles with different sheet thicknesses and, accordingly, with different weights. Naturally - the thicker the sheet - the greater the weight of the material. This means that the truss system of your roof must comply with and withstand the required weight with a margin of safety. The standard sheet thickness is from 0.4 mm to 0.6 mm.

Note!

Often, an unscrupulous seller can offer you thin sheets, passing them off as thicker ones.

It is very easy to check this by using a micrometer and carefully reading the certificate attached to the product.

There will necessarily be described the main parameters of the material.

The minimum sheet thickness is, in principle, acceptable for a conventional standard roofs. But if you want a roof of increased strength, then get more powerful sheets, but first make sure that the truss system is prepared accordingly. The step of the crate in this case should be more frequent, and the main rafters are thicker.

Choosing a coating

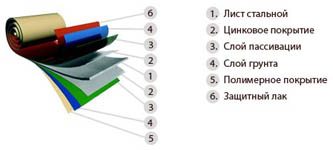

Pie sheets

The next point that you need to pay attention to when buying a metal tile is the choice of the type and quality of the coating. As you know, steel sheets have multilayer protection.

The so-called pie consists of:

- Galvanized layer to prevent corrosion.

- Primer layer.

- polymer layer.

- Paintings.

Protective zinc coating

The material is coated with zinc so that moisture cannot penetrate the steel sheet and destroy it over time. After all, iron is prone to rusting, but zinc is not.

Additionally, the galvanized layer protects the sheets from scratches and other mechanical damage. The norm for manufacturers is the consumption of 100 to 250 grams of zinc per square meter of steel.

Primer layer

The primer is applied for good adhesion of the previous layer to the subsequent ones. If it is not there, the metal tile will last a very short time. A conscientious manufacturer uses only the best formulations in the manufacture of its products. Therefore, do not only carefully study the certificate, but also choose manufacturers with a good reputation.

Varieties of polymer protection

As a polymer coating, as a rule, are used:

- plastisol;

- pural;

- PVDF;

- polyester;

- matte polyester.

Note!

The most durable can be considered PVDF and pural.

They will not only last a long time, but will also please the presentable appearance of your roof.

Of course, all types of coatings differ not only in composition and technical characteristics. They also give the material an exclusive look.

So if you don't want a shiny roof but prefer matt textures, a matte polyester finish is the way to go, giving the roof the look of a ceramic finish. All other compositions give the metal tile a slight sheen.

Note - the thicker the steel sheet - the thicker the polymer coating should be. However, it should be borne in mind that the documentation indicates the thickness of the sheet itself, excluding the polymer layer. If the thickness of the steel is indicated in the amount of 0.5 mm, then in fact it will be about 0.7 mm. The standard coating thickness varies from 50 to 200 microns.

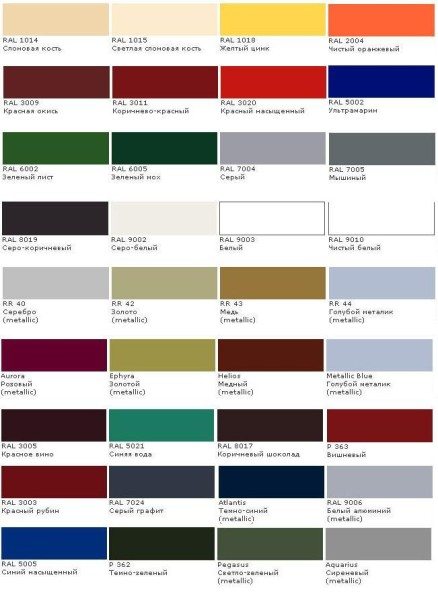

Material colors

To date, there are so many colors and shades of material offered that choosing a metal tile can take you a lot of time. It is very easy to get lost in the rich choice of the proposed range. To make it easier for yourself - select the coating in the first place so that it is in harmony with the color scheme of the house itself.

Well, since you finished your house to your liking, then with color roofs made of metal, most likely, you have previously decided. As a rule, consumers prefer dark reds and browns. All shades of green are in slightly less demand. Next in the ranking are all the other colors.

Strongly dark shades are not recommended for two reasons. Firstly, the darker the roof, the more it heats up from the sun. Secondly, dark colors tend to fade quickly. Warm or cold colors to choose is already a matter of your taste.

Note!

When checking the painted layer, carefully inspect it.

There should be no stains, cracks, scratches or blisters in the paint.

Be sure to check the sheets of tiles with each other - so that there is no difference in shades.

Often there are slightly darker and lighter fragments, and this difference will be very visible on the roof.

What else to consider when buying

When purchasing roofing material, be sure to consider the following characteristics.

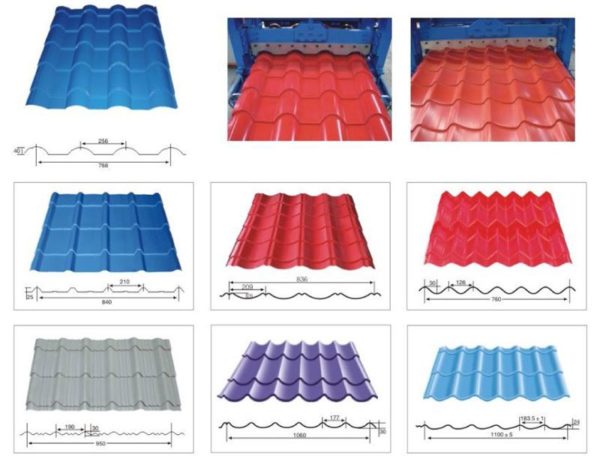

Shape, size and profile height of sheets

Profiled material has a wide variety, which can be classified as follows:

- Metal tile with a small (up to 50 mm) wave height. Widespread and popular option. It looks neat and presentable, it is relatively inexpensive.

- Tiles with high (from 50 mm to 70 mm) wave height. It costs more than the previous version, but is much stronger. It is known that the higher the waves, the more powerful the sheets, and the greater the load they are able to withstand.

- Sheets with symmetrical waves.

- Material with asymmetrical waves. Waves in this case can be uniformly skewed in one direction or another.

- Metal tile with various geometric patterns. This option is considered exclusive, so it is quite expensive. This type of profile can be attributed to elite materials.

Manufacturer of metal tiles

Until recently, the domestic market was literally crammed with material mainly from foreign manufacturers. However, at the moment there are a lot of offers from their manufacturers. When choosing products, you will not see a big difference in prices and quality. Therefore, if you are used to everything imported, as a guarantor of quality, you can choose foreign material.

But it is worth noting that domestic products are in no way inferior to many foreign suppliers. But its cost is often lower with a similar quality. Therefore, the country of origin is not the main indicator.First of all, pay attention to how long this company has been on the market and what its reputation is.

Manufacturer warranties and certificates

Any self-respecting manufacturer must provide a guarantee for their product. Therefore, when purchasing material, first of all, be guided not only by the reputation and name of the company. Ask the seller for all the necessary documentation.

Please take out!

Standard warranty periods for materials with polyurethane coatings (plastisol, pural, etc.) are up to 15 years.

Polyester coated material has a warranty period of up to 10 years.

Note that international standards are much stricter than domestic ones. Therefore, according to foreign standards, according to the standard length of the steel coil, the difference in thickness should not exceed more than 0.01 mm. According to our GOSTs, a difference of 0.05 mm is allowed.

When planning the purchase of roofing material, think carefully in advance. Consider not only your taste, but also all the characteristics that must match the roof. After all, you choose quite expensive products, the duty of which is to reliably serve you for many years.

Did the article help you?