Covering the roof with metal tiles is the most affordable and used solution in the construction of roofs, since it is this material that accounts for about 70% of the total sales of roofing materials. Nevertheless, such material is not without drawbacks: the main disadvantage is the sound insulation of metal tiles, which, at least, leaves much to be desired.

Covering the roof with metal tiles is the most affordable and used solution in the construction of roofs, since it is this material that accounts for about 70% of the total sales of roofing materials. Nevertheless, such material is not without drawbacks: the main disadvantage is the sound insulation of metal tiles, which, at least, leaves much to be desired.

It is about the resolution of this problem that we will discuss in our article.

Causes of noise in metal roofing

Surely, of the entire number of owners of houses with a residential attic or attic space, not one will put up with drumming on the roof during rain or howling in strong winds.

Therefore, solving the problem of soundproofing the roof, especially when combined with living quarters, should be a priority.

Often, poor soundproofing of the roof appears due to its improper installation. Here we are talking about the incorrect cutting of sheets of metal and the likely heating of their near-seam areas, which provokes the formation of deformations.

The deformation of the metal tile during its installation and its insufficiently tight attachment to the crate creates a roofing resonance during rain or strong wind, which many mistakenly take as a sign of a low level of sound insulation of the material itself.

Let's consider, because of what the sound insulation of a metal tile can "limp":

- One of the reasons is uneven cladding for metal roofingmade of materials of different sizes. In this case, such sheet material as a metal tile will sag over some sections of the crate system. It is this kind of "tambourine" that will create flapping sounds even with slight gusts of wind.

- Another reason may be excessive savings on self-tapping screws for metal tiles. According to the technology of laying a metal tile coating, there must be at least 8 screwed screws per square meter of roofing. If less than the specified number of self-tapping screws were screwed into the roof, then, most likely, the “result” will be heard already at the first rain.

Advice! It is better to purchase those self-tapping screws that are recommended by the manufacturer of the roofing material, unless, of course, they are included in its delivery.

- The third reason for the appearance of a knock on the roof during rain may be a small slope angle. And the smaller it is, the more clearly a knock will be heard. But here, with the finished roof, unfortunately, nothing can be done, of course, if we are talking about the sounds heard from outside the house.

How to deal with poor roof soundproofing

First, consider what measures need to be taken to reduce the "noise" of a metal roof:

- Increase the rigidity of the roof structure by properly attaching the metal tile deck to the crate (observe the required number of self-tapping screws per square meter of coverage).

- Correctly mount the rafters. Depending on the length of the rafter legs, the step between them should be 80-110cm.

- Correctly mount the crate. When installing the crate, the flaws and irregularities of the rafter system must be eliminated so that the final crate is perfectly even, without bumps and depressions.

Nevertheless, even with proper installation of metal tiles, its sound insulation is much inferior to almost silent soft tiles. For this reason, additional measures are often necessary to reduce noise levels.

One of the most common methods for additional sound insulation is a single-layer or two-layer laying of insulating material.

Yes, that's how popular it is. roof insulation, like mineral wool, laid on almost every roof, can significantly reduce the noise level.

Soundproofing materials include those whose sound absorption coefficient is more than 0.4. For mineral wool, it is 0.7-0.95, depending on the manufacturing method, which makes it an excellent sound insulator.

The chaotic arrangement of wool fibers makes it elastic, which contributes to the damping of vibrations that are formed when impact noise from raindrops appears.

Such sound insulation for metal tiles is laid as follows:

- First, roll waterproofing is laid on the rafters.

- Then the insulation is stuffed onto a wooden crate.

- To ensure better heat and noise insulation, a special mineral wool 15-20 cm thick is laid on top of the first standard layer of insulation.

This procedure is used for soundproofing a metal roof under construction.

If sound insulation is required under the metal tile of an existing roof, then in such a case, the laying of mineral wool layers is carried out by surprise between the rafter legs.

It is desirable to completely eliminate the collapse or deformation of the material. When cutting noise-insulating insulation under metal tile flooring, among other things, it is desirable to provide tolerances of 7-10 mm in width, allowing you to tightly insert the insulation layer between the rafters.

To avoid crushing the slab, the middle of the material slab is inserted into the span between the rafters, after which the slab is pressed in towards the edges from the center.

When soundproofing a roof made of metal tiles in several layers, mineral wool is first laid between the rafters, and then a second layer is placed between the counter-battens stuffed in addition on the inside.

Vibration isolation device

The task of this kind of insulation is the absorption of shock sound waves. Vibration isolation materials do not absorb noise, but repel it, causing it to lose energy.

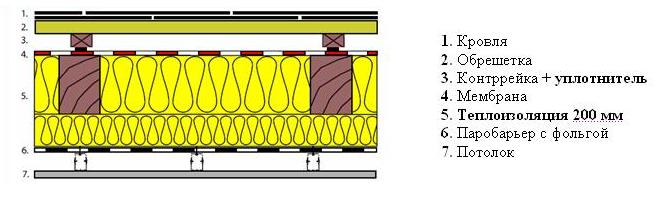

To protect the roof from impact noise, the roof covering is separated from the supporting rafter system. At the same time, a sealant is laid - a gasket made of noise-insulating material between the rafter leg and the counter-lattice.

In other words, when the metal roof is insulated with mineral wool, the lathing is of high quality, the required number of self-tapping screws is used and the roof slope is larger, the sound of rain will no longer bother you, at least knocking on the roof.

Did the article help you?