To the question "Do I need waterproofing under a metal tile?" we can say with confidence - "Necessary!". The fact is that during the operation of a roofing deck made of metal, on its inner side facing the living quarters, condensate forms, which, in the absence of a waterproofing layer, can penetrate into the insulation, which will spoil its operational properties, and even into living quarters.

To the question "Do I need waterproofing under a metal tile?" we can say with confidence - "Necessary!". The fact is that during the operation of a roofing deck made of metal, on its inner side facing the living quarters, condensate forms, which, in the absence of a waterproofing layer, can penetrate into the insulation, which will spoil its operational properties, and even into living quarters.

In this article, we will give recommendations regarding the selection and installation of waterproofing for classic pitched roofs.

Characteristics of waterproofing film for metal roofing

As a waterproofing material for metal tile flooring, a protective vapor-permeable roofing film is usually used, which is designed to protect the attic under-roof space from rain and melt water, dust and dirt, and protect the heat-insulating layer from the penetration of external moisture.

Thanks to its microperforation, such a barrier can provide ventilation for water vapor penetrating from the interior of the building, which the vapor barrier under the metal tile could not keep.

Film roof waterproofing is a material consisting of three layers and having a carrier braided reinforcing mesh made of polyethylene fibers. In addition, the material on each side has a lamination with a polyethylene film.

The ability to use different types and thicknesses of the laminating coating makes it possible to produce various variations of films:

- having fire resistance;

- resistance to ultraviolet radiation;

- various colors, etc.

Approximately 12 cm from the edge of the waterproofing film, as a rule, a green or red colored tape is laid, which indicates the vapor permeability of the material and other information about its properties.

Reinforcement of the film provides it with the necessary strength, and lamination on both sides, with proper installation, provides waterproofing characteristics. The use of hydroperforation allows the film to pass steam through itself.

A standard roll of waterproofing film holds a strip of material 50m long and 1.5m wide, with a specific gravity of 140g/m2.The durability of such a film is usually not lower than the life of the roofing material itself.

It does not rot, is not affected by pests and mold. In addition, the film does not harm human health.

How to lay waterproofing under a metal roofing

Waterproofing for metal tiles is mounted according to the following rules:

- The film is fixed directly on the plane of the log, rafters and other structural elements of the roof. For this, staples with mechanical fastening or stainless steel nails with a flat head are used.

- The step between the lags carrying the film should not be higher than 1.2 m.

- At the end of the laying of the waterproofing, its fastening is reinforced by installing an auxiliary counter-lattice along the slope. For this, it is best to use an impregnated material with a cross section of 5 * 2 cm, then reinforced under the roof. If you ignore the need to install a counter-batten, the fastening of the waterproofing film will not be reliable enough. Among other things, normal ventilation of water vapor from the interior through the film will also not be ensured.

- The use of ventilation elements, such as ventilation grilles, hatches, caps, and others, is applicable in variations in the execution of a metal roof.

Advice! Do not confuse the mounting side of the waterproofing film. The hydrobarrier is laid with the bright side of the tape, located on the edge of the material, to the roofing. When laying the barrier film on the other side, both its waterproofing properties and vapor permeability will deteriorate.

- The material should not be laid directly on the formwork or other flooring, nor should it come into contact with the thermal insulation layer. If it is necessary to install waterproofing, for example, on a reconstructed roof equipped with formwork or flooring of another kind, the issue is resolved by laying a log between the flooring and the film along the roof slope. The lag step should not exceed 1.2 m, while the cross section should be about 5 * 2 cm in size.

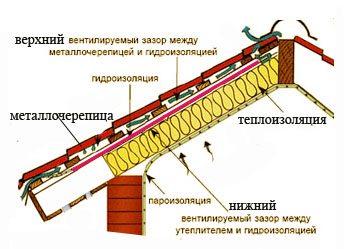

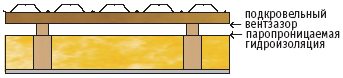

- When the film comes into contact with the flooring, it loses its useful qualities, since they are based on the use of surface tension - the tent effect. To realize this effect, a gap of 4-5 cm must be provided under the roof slope, and the edges of the hydrobarrier must be fastened along the bottom and the ridge of the roof in accordance with the requirements for air circulation in the intermediate layer. All entry and exit points of ventilation air are designed to prevent biological organisms from entering the ventilation layer.

Layout of vapor-permeable waterproofing and under-roof ventilation gap

- On the ridge of the roof, a gap of at least 5 cm is provided for ventilation. In this case, the hydrobarrier should reach the edge of the gutter. If no lower gutter is provided on the edge of the roof, the lower edge of the foil is preferably made in combination with the gutter of the roof itself.

- The colored tape of the film marks the overlap line followed by the waterproofing strip.

Advice! For fastening the hydrobarrier to the protruding elements of the roof, double-sided butyl rubber adhesive tape K-2 is used.

- Violation of ventilation in the gap under the waterproofing in the place where the attic window crashes is eliminated either by drilling side holes in the rafters under and above the attic window, or by installing ventilation inserts in the same places.

- Waterproofing is attached to attic windows, taking into account a certain design solution for this window. Various roof window manufacturers provide different solutions for attaching waterproofing film to their products.

Properly installed waterproofing under the metal tile will bring no less benefit in terms of roof reliability than the roofing itself, since it is the only obstacle to the condensate in the under-roof space.

Did the article help you?