The installation technology of metal tiles is quite simple. However, if you decide to cover the roof with metal tiles yourself, then you should definitely study all the nuances of working with this roofing material - after all, often the final result depends on the little things and subtleties. Therefore, our article will be devoted precisely to the intricacies of working with metal tiles.

The installation technology of metal tiles is quite simple. However, if you decide to cover the roof with metal tiles yourself, then you should definitely study all the nuances of working with this roofing material - after all, often the final result depends on the little things and subtleties. Therefore, our article will be devoted precisely to the intricacies of working with metal tiles.

What is a metal tile?

Before starting work, it is necessary to carefully study the material itself, which we will use to equip the roof.So - what is a metal tile?

The basis of the metal tile is a sheet of high-strength steel, the thickness of which, depending on the brand of the metal tile, can be in the range of 0.4 - 0.8 mm.

Profiled (curved in a certain way to obtain a characteristic profile) roofing steel covered with the so-called "passivating" composition based on aluminum-zinc compounds.

The main role of this composition is to prevent corrosion of the metal base of the metal tile. The passivating layer is covered with several protective layers, and then a layer of polymeric material is applied.

Depending on what type of polymer was used to protect the metal tile, the following types of coating are distinguished:

- Polyester coating

- Matte polyester finish

- Plastisol coating

A separate category is the so-called composite metal tile. It is a metal tile based on a steel sheet with a thickness of 0.45-0.55 mm, which is covered with natural stone chips over a passivating aluminum-zinc layer.

Most often, basalt chips are used for the composite coating of metal tiles.

Note! Unlike traditional polymer-coated metal tiles, composite metal tiles are produced in a much smaller size and imitate traditional ceramic tiles in shape. That is why the installation of a composite metal tile in its technology differs significantly from the installation of a conventional metal tile.

To protect against mechanical damage, as well as from fading under the influence of ultraviolet radiation, the polymer coating is coated with a protective varnish (in one or several layers).In addition to all the above properties, the varnish also increases the water-repellent properties of the metal tile.

Calculation of metal tiles

The key features of the installation of metal tiles are that, unlike slate, corrugated board and other roofing materials, metal tiles have clearly defined upper and lower edges.

This means that on the roof, a sheet of metal tiles must be oriented in a strictly defined way.

Therefore, when purchasing metal tiles for roofing, we must very accurately calculate the amount of purchased material - after all, it will not work to make a section of the roof “from fragments”, arranging them in an arbitrary order.

In addition, one should also take into account the fact that it is necessary to cut the metal tile as little as possible (this point will be discussed in more detail below).

Therefore, for slopes of a rectangular configuration, it is almost always possible to select the number of sheets of metal tiles with the required number of waves, which is necessary to completely cover the slope.

Combining three-six- and twelve-wave sheets (and these are one of the most common sizes), you can do without trimming the metal tile along the width of the slope.

And if the metal tile protrudes beyond the slope along the length, it does not matter: the larger the roof overhang, the better the house is protected from precipitation.

Note! For the convenience of performing calculations, it is more convenient to calculate the amount of metal tiles not in millimeters, but, as we indicated above, in waves.In addition, most major metal tile manufacturers have special calculators on their websites that can be used to calculate metal tiles for almost any roof.

Cutting metal tiles

As we said above, cutting metal tiles is undesirable. This is due to the fact that when cutting a metal tile sheet, the integrity of the polymer and passivating layers is violated, and the metal base of the metal tile becomes vulnerable to corrosion processes.

However, in some cases (for example, when installing a tent or hip roof), cutting the metal tile is necessary.

If you need to trim the metal tile, then for this you can use:

- Hand shears for metal

- Electric nibblers

- Hacksaw with fine teeth

- Electric jigsaw with a blade designed for cutting thin metal

- Circular saw with carbide teeth

Note! Cutting metal tiles with an angle grinder ("grinder") with an abrasive wheel is not allowed! This is due to the fact that when exposed to a high temperature of a rotating abrasive wheel, the polymer coating melts and the passivating layer burns out in the area adjacent to the cut line. At the same time, corrosion processes develop much faster and the metal tile sheet becomes unusable very soon.

When cutting metal tiles, it is best to immediately sweep away the formed sawdust with a soft brush, since metal filings very quickly damage the varnish coating and the polymer protective layer.

For the same reason, it is necessary to metal roof ridge installation in shoes with soft soles, otherwise the protective layer will be damaged by metal heels.

Roof preparation for metal roofing

In order to comply with the installation technology as much as possible, the metal tile is laid on a specially prepared roof. Roof preparation includes two stages:

- Arrangement of waterproofing

- Installation of the batten on the rafters

The waterproofing layer provides the waterproof characteristics of the roof, therefore, the better the waterproofing is laid, the more reliably our house will be protected from precipitation. Waterproofing is laid as follows:

- The direction of laying the waterproofing material depends on the slope of the slope. If the metal tile is laid on a slope with roof slope more than 1:5, then the waterproofing material is laid parallel to the ridge. In the event that the roof slope has a slope of less than 1:5, the waterproofing is laid in the direction of the slope from the eaves to the ridge.

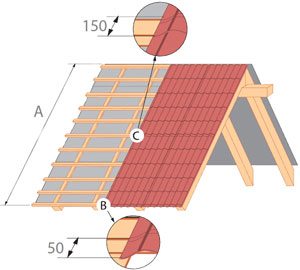

- The slope of the slope also determines the overlap of the sheets of waterproofing material: with a slope of 15-30 °, the optimal overlap is 250 mm, and with a slope of 30 ° or more, an overlap of 150-200 mm will be sufficient. When covering a hip roof with a metal tile, the overlap on the ridges is increased by 50 mm.

When installing a metal tile, there are two ways to lay a waterproofing carpet:

- The first method involves laying waterproofing in such a way that the waterproofing material does not touch the insulation anywhere. At the same time, ventilation of the intra-roof space is provided due to the gap.We can get this gap by stuffing an intermediate crate made of timber with a section of 50 mm onto the rafters - it makes it possible to lay waterproofing with a sag of about 10-20 mm. However, this method of laying waterproofing has one very significant drawback - along with roof ventilation, heat loss increases.

- The second method is more rational in terms of thermal insulation, as it involves the use of waterproofing vapor-permeable membranes. On the one hand, such membranes perfectly protect the roof from leaks, and on the other hand, they do not prevent the diffusion of water vapor from the thickness of the insulation under the roof. An additional advantage of such membranes is that, along with waterproofing and ventilation functions, they also have high windproof characteristics.

The waterproofing is fixed to the rafters or intermediate battens either with galvanized roofing nails or with construction stapler staples. On top of the waterproofing on the rafters, we fill the slats of the battens, which are designed to prevent damage to the membranes during the installation of the batten.

The configuration of the crate is determined both by the design of the truss system and the configuration of the metal tile, while a continuous crate for metal tiles is almost never used.

For example, the installation of a metal roof tile (according to the official recommendations of the manufacturer of this tile) involves the construction of a crate with the following characteristics:

- For a roof whose rafter pitch is in the range of 900-1200 mm, the lathing is erected from wooden slats 32x100mm

- It is also possible to use a metal profile with the same (or greater) bearing capacity

- The crate is fixed to the rafters or counter-rails with nails or self-tapping screws.

- The bottom rail of the crate should be at least 10 mm thicker than the others.

Note! It is best to start the installation of the crate from the same place from which the laying of the metal tile will subsequently be started. This will facilitate the joining of sheets of roofing material during the construction of a roof of complex configuration.

Also, when installing the crate, it should be remembered that if the metal tile itself is not damaged, the repair of the crate can be carried out quickly enough. And this means a significant extension of the life of the roof as a whole.

Installation of metal tiles

So, all preparatory work is completed. It's time to proceed directly to fixing the sheets of metal on the crate.

To fix the sheets of metal tiles, we use roofing metal screws with a drill (4.5x25 and 4.5x35 mm). The hexagonal head of the self-tapping screws allows the use of a cordless screwdriver with a special nozzle for mounting, which greatly facilitates and speeds up the work.

To ensure more reliable fixation and waterproofing at the attachment points, each self-tapping screw must be equipped with a sealing polymer washer.

Note! The use of such fasteners greatly simplifies the dismantling of the metal tile if it is necessary to overhaul the roof. At the same time, we mark the removed sheets of metal tiles, and upon completion of the repair, we return them to their place, fixing them with self-tapping screws into the already drilled holes.

Installation of metal tiles is carried out according to the following algorithm:

- Before starting installation, we install a cornice strip on the lower end, designed to protect the crate and frontal board from the influence of precipitation. We fasten the plank directly to the crate using countersunk screws or galvanized steel roofing nails. We install a sealant between the cornice strip and the sheets of metal.

- Installation of a gable roof starts from the end of the roof, hip - from the eaves. Sheets of metal tiles are aligned relative to the eaves, and not relative to the end.

- The stacking of sheets can be carried out both from left to right and from right to left. When laying from left to right, each subsequent sheet starts under the previous one, and when laying from right to left, it is superimposed on top of the previous one.

- The optimal overlap along the slope is 250 mm. However, some types of metal tiles are made to the size of the roof, so when arranging a roof with such sheets, overlap is not needed.

- Sheets of metal tiles are attached to the crate in the lower part of the profile wave and under the transverse wave. Fastening is carried out through a longitudinal wave in every second transverse wave of a metal tile sheet.

- The capillary groove on the left side of each sheet must be overlapped by the overlap of the next sheet. The overlap is fixed with a self-tapping screw 4.5x25, while additional sealing of the overlap with waterproofing compounds is not allowed.

The work on the installation of metal tiles is being completed with the installation of valleys, ridge slats and end slats.

When arranging the ridge with a step of 5-6 meters, so-called ventilation strips can be installed, which are a ridge strip with ventilation holes.

As you can see, even such material as a metal tile can be mounted on its own - its installation technology is quite simple and does not require any extraordinary skills or complex expensive tools.

But still, without preparation, it is not worth taking on the installation of metal tiles on a complex-shaped roof. So if possible, practice “on cats”, covering a small gable roof of a barn or country house with a metal tile.

Did the article help you?