Recently, in the construction of civil and industrial buildings, flat roofs are increasingly used, in which, unlike pitched varieties, piece and sheet materials are not used. The device of a flat roof provides for laying a carpet of roofing material, it can be mastics, as well as bitumen, polymer and bitumen-polymer materials.

Recently, in the construction of civil and industrial buildings, flat roofs are increasingly used, in which, unlike pitched varieties, piece and sheet materials are not used. The device of a flat roof provides for laying a carpet of roofing material, it can be mastics, as well as bitumen, polymer and bitumen-polymer materials.

flat roof carpet must have elasticity, which allows softening the mechanical and thermal deformations of the base, which is used as heat-insulated surfaces, screeds and load-bearing plates.

Varieties of flat roofs

The flat roof device includes several types of roofing:

- Exploited roofs are used on buildings, people regularly go to the roof, or there are various heavy objects on it. Their distinguishing feature is the device for waterproofing either a rigid base or a special screed in order to ensure the reliability of the roof under the influence of heavy loads, which are most often unevenly distributed over the surface.

- Unused roofs in buildings such as flat-roofed bathhouses, where there is no need to lay a rigid base, as there is no maintenance of the roof and surface pressure is minimized. When it becomes necessary to maintain or repair the roof, special bridges or ladders are used to distribute pressure over the entire surface of the roof. This type of roofing requires less construction costs, but their service life is also reduced.

- Classical roofing, also called soft roofing, is a load-bearing slab on which a layer of heat-insulating material, such as mineral wool boards, is laid on top of the vapor barrier layer. To protect the thermal insulation layer from the effects of precipitation, a waterproofing layer based on rolled materials containing bitumen is also laid on top of it. Such roofs are the traditional covering for buildings such as flat roof frame houses, etc.

- Do-it-yourself inversion flat roofs differ from traditional ones in that the insulation layer is located on top of the waterproofing carpet, preventing its protection from ultraviolet radiation, temperature extremes, freezing and thawing cycles and various mechanical influences, increasing the life of the roof. Such a roof can also be used as an operational one, you can walk on it, put furniture, arrange a small garden or greenhouse.

- In ventilated roofs, the first layer of the carpet is glued to the roof either partially, or instead of gluing, it is fastened with special fasteners, preventing the formation of air bubbles due to moisture accumulating in the insulation layer, causing ruptures and leaks of the roofing carpet. At the same time, a flat wooden roof is also protected from the effects of excess water vapor pressure with the help of an air space formed between the base and the roof.

Before repairing a flat roof, you should clarify what type it is and whether it is safe to walk on it, or whether special equipment must be used to increase reliability.

Foundation preparation

Almost any flat roof in section is a base on a bearing coating, on which layers of steam, heat and waterproofing are laid.

Most often, a steel profiled sheet or reinforced concrete slab is used as a bearing coating, less often a wood coating is used.

In the case of an uneven base made of reinforced concrete, a cement-sand screed should be made to allow it to be leveled.

The thickness of the screed depends on the material on top of which it is laid:

- when laying on concrete, the thickness is 10-15 mm;

- on rigid insulation boards - 15-25 mm;

- 25-30 mm - on non-rigid insulation boards.

In the case when the roof slope does not exceed 15%, the screed is first placed on the grooves, and only then on the slopes, but with a slope of more than 15%, the screed procedure is performed in the reverse order - first, the slopes are leveled, then - valleys and grooves.

Almost all modern flat roof houses have building elements protruding above it, such as parapet walls, chimney pipes, etc. These elements should be plastered to a height of at least 25 centimeters.

Special rails are attached to the upper edge of the surface covered with plaster, on which the rolled carpet will be attached. To improve the adhesion of the carpet to the base, the screed should be primed with roofing mastics, having previously been cleaned of debris and dried.

Coating a flat roof with mastics

Roll materials may not be included in the calculation of a flat roof; instead, mastics can be used as an independent roofing material - liquid materials based on purified polyurethane resins with good hydrophobicity and elasticity.

When applied to a flat surface, such as a flat roof, the mastic polymerizes under the influence of moisture in the air, forming a membrane that resembles rubber in composition. This membrane has good waterproofing and protective properties.

Mastic, in addition to its versatility, provides a number of advantages specifically for flat roofs, such as safety, reliability, increased adhesion to building surfaces, resistance to precipitation, microorganisms and ultraviolet radiation.

In addition, it is quite easy to use when covering a flat roof, it can be applied with a roller, brush on the bases in the form of a cement-sand screed or reinforced concrete slabs.

As the climate changes regularly throughout the year and flat roofs are subjected to particularly strong weather effects, they must be as resistant to such influences as possible.

In summer, the temperature of the roof, which is under the direct action of the rays of the sun, rises to + 70 °, and in winter it can drop to -25 °, therefore, when deciding how to cover a flat roof, it should be borne in mind that a high-quality sealant should withstand a temperature difference of at least 100°.

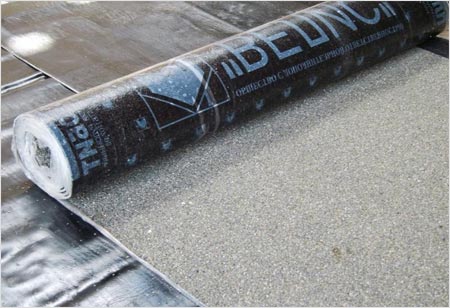

Covering a flat roof with roll materials

When covering a soft roof with rolled materials, the panels are overlapped on the slopes, that is, each laid layer overlaps the joints of the elements of the previous one.

If the roof slope exceeds 5%, then the outer width of the overlap is 100 mm, and the inner width is 70 mm. In the case when the slope does not reach 5%, the width of the overlap of all layers should be at least 100 mm, however, it should be remembered that, for example, for hip roof calculation data will be completely different.

In interleaved layers, the overlaps do not overlap, but are located at a distance equal to half the width of the roofing material roll. All lanes are laid in the same direction.

Useful: if the panel deviates during the gluing process, you should try to return it to its place without peeling it off. If it is not possible to displace, the glued piece of cloth is cut off and glued again, observing an overlap of 100 mm.

The panels should be laid in layers, in case of fixing roofing materials on mastic, the layers should be glued at intervals not less than 12 hours.

Thermal insulation of flat roofs

In the case of a flat roof without an attic, both internal and external insulation methods can be used.

The external method is more common due to its ease of implementation, allowing you to insulate both the roof of a building under construction and already in operation.

There are two types of flat roof thermal insulation devices: single-layer and double-layer. A specific solution is selected in accordance with thermal engineering calculations and strength requirements for roofing.

Thermal insulation slabs are laid on the supporting structure in compliance with the principle of "spread seams". In the case of two-layer insulation, the joints of the lower and upper plates must also be done "in a row".

In those places where the thermal insulation slabs are adjacent to walls, parapets, lighting fixtures, etc., transitional sides for thermal insulation are equipped.

Thermal insulation is fastened to the base in various ways:

- glue method;

- Fastening using ballast (pebbles or paving slabs);

- Mechanical fastening in the form of self-tapping screws when fastening corrugated board and dowels made of plastic with a core for a reinforced concrete base.

Did the article help you?