The abundance of roofing materials - profiled sheets, metal tiles, natural coatings today competed with slate. But, nevertheless, it remains popular in country, individual construction. In this article we will describe what features flexible slate has, as well as other types of slate sheets (galvanized, asbestos).

The abundance of roofing materials - profiled sheets, metal tiles, natural coatings today competed with slate. But, nevertheless, it remains popular in country, individual construction. In this article we will describe what features flexible slate has, as well as other types of slate sheets (galvanized, asbestos).

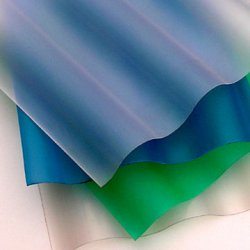

Flexible fiber sheets

Flexible slate is also called "bituminous slate". It is made from mineral, synthetic or vegetable fibers and impregnated with distilled bitumen.

The fibers are processed under high pressure and high temperature. As a result, the water resistance and strength of the roofing material increase.

The use of flexible slate is possible on roofs with a slope of more than 5 degrees, the maximum slope of the slope is not standardized.

The manufacturer produces flexible rectangular roofing sheets with a wavy profile. In appearance, they resemble asbestos-cement sheets, which we will discuss in this article a little later.

The outer surface of the sheets is treated with acrylic or vinyl paint. In addition to the fact that the paint protects the coating sheet slate from ultraviolet radiation, it will allow you to move away from the stereotypes associated with the grayness of asbestos sheets.

Thanks to the paintwork, which includes persistent pigments, you can get green, black, brown, red slate, which allows you to expand the design possibilities for the exterior design of the house.

The inner surface of the flexible sheets has an uncovered bituminous layer, which causes the creation of a waterproof coating on the roof.

Flexible roofing material has various versions:

- Ondulin - soft slate - the wave characterizes its appearance. This French-made coating consists of organic fibers, bitumen, rubber, minerals and coloring pigments. Due to its plasticity, it can be used for slate laying on flat and uneven roofs. The weight of one sheet is 6 kg, and the thickness of the slate is 3 mm. This is a fairly simple and easy-to-install material that has a standard set of additional elements;

- Nulin is almost similar to ondulin: it is durable, strong, and has high heat resistance. One sheet weighs no more than 8 kg. It also has a wavy profile and is quite easy to mount;

- The combination of wave + slate has gutta roofing, which is somewhat different from the two materials mentioned above in composition and properties. This material is reinforced with organic fibers. The top layer is more resistant, as it is impregnated with dyes and resins. Corrugated sheets have elasticity, which allows them to be used on a curved surface. Compared with ondulin and nulin, gutta wins in price, but is inferior in properties;

Advice. Experts recommend using gutta roofing not in residential, but in industrial construction. Frequent lathing is used for the flexible coating device, since bituminous materials are subject to temperature changes.

metal slate

In principle, if we have touched on the topic of non-traditional slate, then it is worth stopping at metal slate.

Galvanized slate is made from sheet steel on special equipment, giving it a wave shape.

Various profiles are available:

- arched;

- transversely bent.

Previously, it was appropriate to use metal slate to cover the roofs of hangars, warehouses, industrial premises.

Thanks to the development of technologies: the application of a polymer-decorative coating to the surface of sheets, it began to be used for the roofs of country houses.

Galvanized slate has the following comparative advantages:

- compared to flexible sheets, it has greater hardness;

- in comparison with profiled sheets, it does not heat up much under the influence of sunlight;

- unlike bitumen sheets, galvanized sheets are more fire resistant;

- compared to metal tiles, they have good sound insulation.

In addition, metal slate is much cheaper than other roofing materials, is resistant to corrosion, is easy to repair, and has a light weight, which makes it easier to transport it to the roof.

asbestos slate

No matter how fast new roofings occupy their niche in the market and gain popularity, in our minds, corrugated slate (asbestos) is associated with the concept of cheap roofing and easy installation.

It is produced by forming a mixture of asbestos, cement, water and curing.

Asbestos fibers act as reinforcement in this roofing, which provide the material with:

- impact strength;

- tensile strength.

Several modifications of asbestos corrugated sheets are produced:

-

- Slate ordinary has a rectangular shape. In addition to the main sheets, parts are produced to cover the ridge, valley, roof intersections with various protruding elements - dormer windows, chimneys, etc.;

- The slate strengthened from ordinary sheets differs in the big size. The purpose of this material is the installation of roofs of industrial facilities;

- Unified slate is becoming more popular due to the fact that it is larger in size than ordinary sheets, but smaller than reinforced ones.

The thickness of asbestos sheets is from 5 to 8 mm, and the reference weight is 21 kg.

To increase the service life and improve the decorative properties, corrugated asbestos sheets are painted with silicate paint with pigments, which gives the following advantages:

-

-

- a protective layer is formed on the surface;

- the rate of water absorption decreases;

- the product is protected from destruction;

- increased frost resistance.

-

Corrugated sheets are used in the arrangement of roofs of structures for any purpose, while smooth slate, produced from the same components as corrugated, is recommended for:

- external facing of industrial buildings;

- building fences;

- as fences and partitions;

- production of ventilation shafts;

- flooring.

Smooth sheets have a flat surface, but have the same properties as wavy ones.

Installation of corrugated slate

Installation of corrugated slate is carried out along the crate with a maximum allowable pitch of 550 mm.

Sheets are stacked in several ways:

- with offset edge;

- in a run.

The first method involves fitting the edges of adjacent elements, therefore it is more laborious, but less expensive.

The second method is due to the overlap of adjacent waves from the lateral and transverse sides, which increases the consumption of slate. Fastening is carried out with special nails.

Attention. If you are fastening an eight-wave slate, then the fasteners are placed along the 2nd and 6th waves to avoid warping of the material. The process of driving nails weakens the strength of the slate, so you must first prepare holes for nails, screws or screws, and then fix them. Fasteners are used with rubber seals. Excessive pinching may cause sheet cracking.

In this article, we examined several types of slate, which allows us to emphasize its properties and compare it with other coatings. It remains only to say that the price of ordinary and flexible slate has a difference of about half.

Did the article help you?