Slate is a traditional building material used both in the construction of dachas and country houses, as well as industrial, warehouse and public buildings. This article will talk about what advantages this material has and what features distinguish the production of slate.

Slate is a traditional building material used both in the construction of dachas and country houses, as well as industrial, warehouse and public buildings. This article will talk about what advantages this material has and what features distinguish the production of slate.

The main advantages of slate are:

- Low cost compared to other roofing materials;

- Simplicity and convenience slate installation;

- Resistance to low temperatures;

- Increased density, providing fairly good sound insulation;

- Environmental safety for the environment and human health;

- Fire safety slate roof;

- A wide range of different types and types of products.

Specific features of slate production

Currently, slate production in our country is constantly growing, despite the fact that this material has been used in construction for quite a long time and many consider it obsolete.

At the same time, it should be borne in mind that the technology for the production of slate also does not stand still and is constantly being modernized and improved, as well as the equipment used for the manufacture of this material.

Talk about the fact that slate is outdated and has lost its relevance is completely groundless and not objective enough.

Currently, the production of such material as slate is a fairly profitable industry, since there is a fairly stable and stable demand for the final product produced.

The main technologies that equipment for the production of slate uses today are the technologies for the production of three types of slate:

- Asbestos slate;

- Metal slate;

- Euroslate.

Let's look at these three varieties in more detail:

- In the production of asbestos slate, such a natural component as asbestos is used. It is this material that gives such strength to slate due to the presence of fibers in the composition, which break up into separate components during the production process and ultimately form something like a reinforcing mesh.

- metal slate, or, as it is often called, corrugated board, is a fairly common type of slate. For the manufacture of this material, galvanized sheet steel is used, on which, in most cases, an additional protective polymer coating is applied.The production of metal slate requires the use of special equipment, the main principle of which is the profiling technology.

- Euroslate is produced mainly in foreign European countries. This is due to the fact that, according to the results of tests and tests of ordinary asbestos slate, it was found that one of the varieties of asbestos poses a certain threat to human health. In this regard, European manufacturers decided not to use any kind of asbestos at all in the production of slate. . Instead of asbestos, they use materials such as cellulose, jute, fiberglass and basalt fiber.

How slate is made

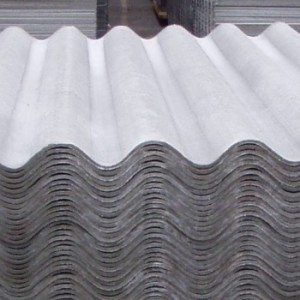

Slate is currently most often called any roofing materials made in the form of corrugated sheets.

In addition to the most widely used sheets of asbestos-cement slate, concepts such as euroslate in the form of corrugated bitumen sheets and asbestos-free slate are used.

In addition, natural slate, that is, natural slate, is quite widely used in construction. But the classical understanding of slate implies precisely sheets of asbestos cement, the production technology of which will be discussed below.

Wavy and flat sheets of asbestos-cement slate are made from asbestos, water and Portland cement.

Asbestos is a natural raw material whose fiber strength is superior to that of steel wire. In addition, these fibers adhere to cement with sufficient quality, after which the material hardens, resulting in a sufficiently strong material resembling stone.

As a result of mixing asbestos fibers with cement, a so-called reinforcing mesh is formed, which gives the slate the necessary strength.

Slate and other asbestos-cement materials are popular in our country not only because of their high strength.

In addition, they have good resistance to cold, fire and high temperatures, moisture. Sheets of this material are not subject to corrosion, are light in weight and are easy to install.

Useful: on the territory of our country there are deposits of most varieties of asbestos, but the most popular in the production of building materials is chrysotile asbestos.

In the production of slate, the quality of the material obtained depends on a number of factors:

- The quantitative ratio of cement and asbestos;

- Uniform distribution of asbestos fibers in cement;

- The fineness of grinding asbestos;

- Length and diameter of asbestos fibers, etc.

Good performance on the listed parameters and ensure the strength and durability of slate.

Foreign manufacturers use in the production of asbestos-cement slate sheets special metal gaskets that form a “wave”.

In our country, until recently, slate was made according to the outdated non-lining method, but at the moment, many domestic manufacturers have also switched to modern technologies.

In addition to the use of gaskets, Russian manufacturers have also mastered the technology of coloring slate, which allows not only to significantly improve the decorative characteristics of the material, but also to increase the overall resistance to wear.

To perform durable staining, silicate or phosphate paints are used, after coating with which the resistance of the material to moisture, sun and various mechanical influences increases.

The harmfulness of asbestos to the human body gives rise to many disputes, and in many European countries the use of asbestos cement slate is prohibited by law.

Here it should be taken into account that only asbestos from the amphibole group, which is not mined in Russia, poses a health hazard. The chemical composition of this asbestos differs from the harmless form of chrysotile asbestos associated with cement, which is used in more than sixty countries around the world.

Important: Despite the harmlessness of chrysotile asbestos, slate workers must take precautions to ensure adequate respiratory protection.

Slate production is one of the leading sectors of the construction industry, since this material is used everywhere and its popularity will remain quite high for many more years.

Did the article help you?