This article talks about how a thatched roof is built with your own hands and how to make it the most high-quality and reliable.

Thatched roofs in European countries today are considered an elite expensive coating, the price of a square meter of which reaches 150 euros.

Such a high price of the material is associated with a number of factors:

- Environmental Safety;

- Deficiency of this material;

- Manual roofing installation technology, etc.

Useful: to qualify as a craftsman who knows how to make a thatched roof, you need to have an experience of 3 to 5 years, and the training lasts one to two years.

In our country, thatched roofs (for example, the thatched roof of a hut), the demand for which is increasing every year, are made according to European technologies.

This type of roofing is most popular in private construction due to the relatively high cost of the material and its installation.

Despite this, thatched roofs can end up costing as much as tiled roofs because they don't require thermal and waterproofing.

Roof mounting with screws

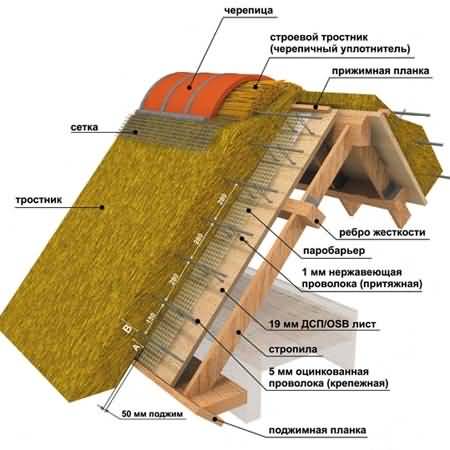

If the straw roof is mounted on screws, the sheaves, pressed with wire, are fastened to the closed flooring.

Fiberboard, multi-layer plywood, glued chipboard, etc. are used as the material for the manufacture of sheathing boards.

Important: Depending on the length of the screws, the minimum shield thickness is 18 mm.

Sheaves of straw are a rather important part of the roof insulation, the gap between them and the lower structure is not made, since the lower structure is airtight.

This allows you to separate the inside from the outside and get a reliable, comfortable and fireproof thatched roof as a result.

The surface of the lower structure should be made even, dry, clean, strong enough and not damaged. In addition, its tightness is an important factor.

It is also important to pay special attention to elements that pass through the thatched roof, such as chimneys and attic windows.

For the manufacture of thatched roofs, freshwater reeds of the highest quality are used, consisting of straight, strong and flexible mature stems, which should not have leaves.

The following reeds are not allowed for use:

- Burnt;

- Moldy;

- Rotten;

- Mixed with grass, branches or stubble.

For making thatched roofs and laying reeds, the following minimum slope angles are required:

- In the case of a small roof, when the length of the slopes does not exceed 2 m, the attic windows have even slopes, the minimum angle is 30 °;

- The minimum angle in the case of a large roof is 40°;

- With round slopes of roof windows - 30 °.

Important: It should also be taken into account that laying reed on a roof with a pitch angle of less than 45° leads to a significant reduction in the life of the thatched roof.

Consider the main nuances of the construction thatched roof structures:

- During the construction of a conventional roof, minimum roof slope is 45 °, old reed can be used as the first layer, as well as loose stems and tops of cattail.

Important: if a thatched house includes such a layer, it can be visible no more than two-thirds from the bottom edge of the roof.

- The maximum allowable inclusion of loose stems in the reed itself is 2%. You should also monitor compliance with each other in the length and thickness of individual reed stems, the thickness of the sheaf of reeds, as well as the established layer.

- In those places where the straw protrudes beyond the boundaries of the lower structure, it is compressed by 4-6 cm, depending on what wind load is expected in this region. Compression is performed in the direction of the outer surface, leaving no gaps. The reed should fit snugly against the inner edges of the roof, while protruding from the clamping bar by about 15 centimeters.

- Wire clamps are made of galvanized steel wire. The first clamp is placed at a distance of 20 cm from the clamping bar, the second - at a distance of 12 cm from the first.The distance to each subsequent layer is 28-30 cm.

- The reed is fastened rather tightly at the distances given above for clamps; sheaves are stitched to the corner beams with a thin steel wire in increments of 22 centimeters.

- If the distance between the clamping bar and the top of the roof does not exceed 7 m, the slope of the roof is more than 40°, and the length of the reed is less than one and a half meters, the thickness of the reed layer laid near the base of the roof should be at least 25 cm. The thickness of the layer near the top of the roof is as a minimum of 22 cm. A wear layer of at least 9 cm should also be made. If the distance between the plank and the top exceeds 7 m, the slope of the roof does not reach 40 °, or the length of the reed is more than 1.5 m, then the thickness of the layers will be 28 and 25 cm, and the wear layer is 10 cm.

Installing a thatched roof on a level base allows it to remain level. Depending on the time of the year and where the reed is harvested, this material can have different colors, lengths and thicknesses, which is quite common on new roofs.

These differences almost completely disappear after a year of operation of the roof and do not affect the quality of its coating.

During installation roof ridge the reed should protrude to a height that allows leaving a distance not exceeding 6 cm between the reed and the ridge, while the length of visible stems should also be no more than 6 cm.

These requirements must be observed when building thatched roofs.

Due to the fact that roofing is done by hand, the quality of the roof will vary as a result, and compliance with these requirements allows you to ensure good roof quality, respectively, increasing its life.

Sheaf garter

Permanent tying of sheaves can be done in the following ways:

- Wire stitching. If the roof simultaneously functions as a ceiling, two people can perform the flashing - one flashes from the outside, the other directs from the inside. The firmware is performed with a needle through which a wire is threaded. At the same time, the guide from the inside helps to return the needle back around the beam. In the absence of access to the roof from the inside, a rounded needle with rings to which the wire is attached is used for flashing. This method is quite laborious and is almost never used today.

- Firmware with screws to which the wire is attached. Screws replace the wire passed under the roof, and fastening is carried out to the roof beam or lathing. The wire to the screws should be attached in advance, providing a length sufficient to flash the entire roof. This method is quite fast and simple, in addition, it does not require an assistant.

- Stitching with nails can be done with the correct installation of the grid, which must withstand this load. This method is also fast and convenient, but the use of a large number of nails significantly increases its cost.

- Stitching with constrictions (pieces of wood, wire or bamboo stalks) 8 mm long can also be used to attach bundles of reeds to the roof. This method is most often used when decorating the roof and its individual elements.

In order to finally level the straw, compact it and give it a neat appearance, it is knocked out with a special spatula-bit, forming a dense layer.

The construction of a thatched roof is a rather laborious and painstaking process, but the result is a relatively inexpensive, environmentally friendly and reliable roof that can serve reliably and efficiently for many years.

Did the article help you?